You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Can someone familiar with Beersmith help me setup my equipment or link me to a guide?

- Thread starter bhamade

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

I'll try to help.. Let's hear about your set up

I have a 30 gallon Blichmann Brew Kettle as my boil ketter/hot liquor tank. It has the hop blocker addon and a diptube, so there shouldn't be much lost in the final boil. I plan to mainly do 10 gallon to 15 gallon batches. I have a Mash Hawk for a Mash Tun: http://www.irpinconline.com/HomeBrew_Solutions/Tech_Specs.html

I use these burners with a 30 psi regulator although I am about to switch it over to natural gas: http://www.northernbrewer.com/shop/cast-iron-banjo-burner-burner-only.html

I use a pump to pump the water from the kettle to the mashtun, then I pump the wort back into the kettle for the final boil. I do a vorlauf and run the wort back through itself before I pump it into the kettle. Then it goes kettle through a chiller into whatever I am fermenting in. I use glass and buckets both.

If I forgot to mention any parts of my system let me know.

I use these burners with a 30 psi regulator although I am about to switch it over to natural gas: http://www.northernbrewer.com/shop/cast-iron-banjo-burner-burner-only.html

I use a pump to pump the water from the kettle to the mashtun, then I pump the wort back into the kettle for the final boil. I do a vorlauf and run the wort back through itself before I pump it into the kettle. Then it goes kettle through a chiller into whatever I am fermenting in. I use glass and buckets both.

If I forgot to mention any parts of my system let me know.

Sorry.. been away let me read your post closely

Your set up sounds top notch. Have you brewed 5 g batches of all grain before?

Your set up sounds top notch. Have you brewed 5 g batches of all grain before?

Yes, but it was before I upgraded to the Blichmann Kettle. Before I was using a keggle and did 5 gallon batches of recipes I found on here to learn the ropes. Now that I have my workflow dialed in I've upgraded to the Blichmann and want to use Beersmith to be more scientific with my brewing and recipe formulations.

Here's a download to BeerSmith. Good program. Free for three weeks and if you like it it's 25 bucks or so to own. It will help you out more than I can. http://beersmith.com/download-beersmith/

Edit You already have beersmith?

Edit You already have beersmith?

Okay.. wasn't paying attention. Upgrading is same same. Most important factors only you will know about your system and plug into BSII. Boil off rate, mash tun loss, kettle loss. Do some experiments to find the numbers and plug them in. Might take a few times to get it dialed in but then you'll be good. Make sure you update your equipment and batch size profile. If your equipment profile isn't in beersmith you can add it.

Here's a download to BeerSmith. Good program. Free for three weeks and if you like it it's 25 bucks or so to own. It will help you out more than I can. http://beersmith.com/download-beersmith/

Edit You already have beersmith?

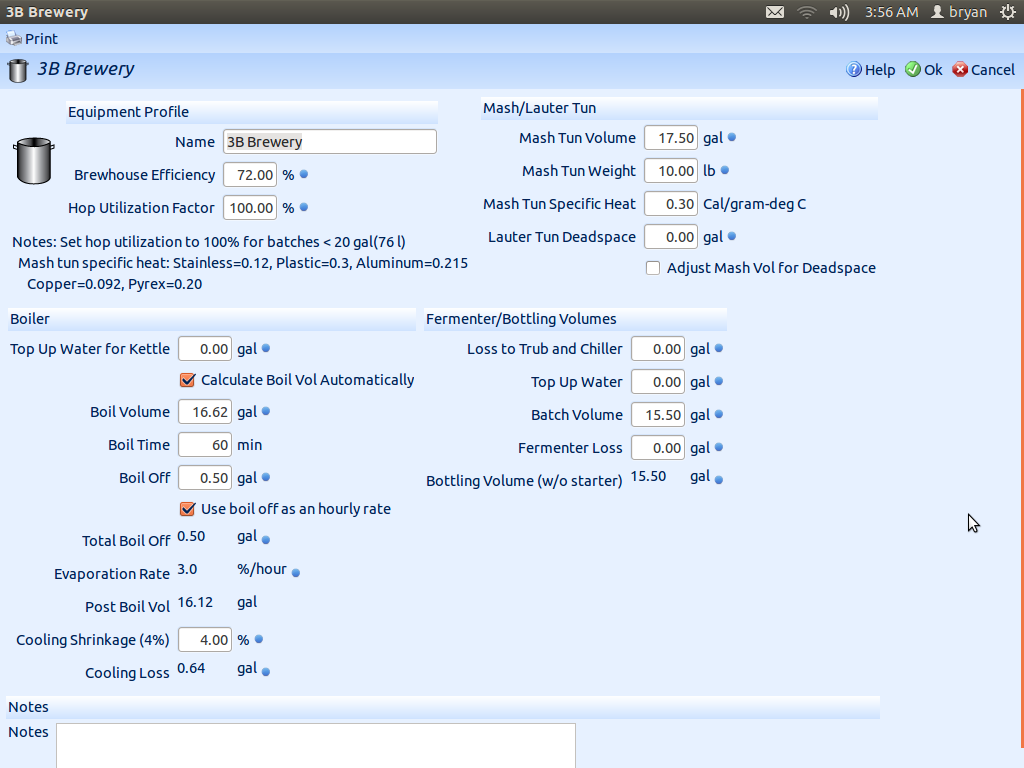

Yes I do. I need help setting up the equipment section for my setup. I think I did it properly, but I'd like a second opinion. Here's my setup now, let me know if anything needs changing.

Boil off rate looks a bit low. I'd do a test to determine boil off per hour. Boil 5 g of water, note the agressiveness of the boil and try to maintain that in your wort boil. Measure after cooled. The loss is the boil off/hr. Not a percentage. Just how much you will boil off in an hour, whether it be a 2 gallon boil or 15.

Mash ton loss was zero? That's pretty good but unrealistic. Put some water in the tun, let it drain with the siphoning tube installed, just as if you were draining it during a brew session. Whatever amount of water left over is the mash tun is dead space.

Also wort lost to trub/cooling lines(plate chiller) need to get an idea of that as well

Mash ton loss was zero? That's pretty good but unrealistic. Put some water in the tun, let it drain with the siphoning tube installed, just as if you were draining it during a brew session. Whatever amount of water left over is the mash tun is dead space.

Also wort lost to trub/cooling lines(plate chiller) need to get an idea of that as well

I will measure the boil off and dead space tomorrow. I didn't change the number to 0 it was already set to 0 and I never edited it. I will get on it tomorrow.Boil off rate looks a bit low. I'd do a test to determine boil off per hour. Boil 5 g of water, note the agressiveness of the boil and try to maintain that in your wort boil. Measure after cooled. The loss is you boil off/hr. Not a percentage. Just how much you will boil off in an hour, whether it be a 2 gallon boil or 15.

Mash ton loss was zero? That's pretty good but unrealistic. Put some water in the tun, let it drain with the siphoning tube installed, just as if you were draining it during a brew session. Whatever water amount of water left over is the mash tun dead space.

Also wort lost to trub/cooling lines(plate chiller) need to get an idea of that as well

As far as the wort loss to the cooler, I have a technique I use that minimizes losses going through the chiller. I've actually measured that before and there was less than a quarter of a regular pint glass. The trub loss won't be measurable until I make my next batch.

Thank you so much for your help man. If you ever make it to Georgia free beers for you my friend.

Thanks bhamade

It will take a little dialing in, maybe one or two or three brews to gets things set. Patience as you know is a key to brewing good beer.

Doubt I'll get down to Georgia but would take you up on the offer if I was closer.

Do have a question for you, how the heck do you get those screen shots put up on here?

Cheers and happy brewing!

Dan

It will take a little dialing in, maybe one or two or three brews to gets things set. Patience as you know is a key to brewing good beer.

Doubt I'll get down to Georgia but would take you up on the offer if I was closer.

Do have a question for you, how the heck do you get those screen shots put up on here?

Cheers and happy brewing!

Dan

Thanks bhamade

It will take a little dialing in, maybe one or two or three brews to gets things set. Patience as you know is a key to brewing good beer.

Doubt I'll get down to Georgia but would take you up on the offer if I was closer.

Do have a question for you, how the heck do you get those screen shots put up on here?

Cheers and happy brewing!

Dan

Open up whatever you want to screenshot and make it fullscreen. Then hit the print screen button. Then open up any image editing software and hit ctrl+v. Then save the document to wherever you want. Then go to imgur.com and upload the image to there. Then copy the link under direct link on the right hand side then hit the image button on here and paste in the url. It sounds really long, but it only takes about one minute if you know what you're doing.

Okay will give that a try. Just copied, pasted and printed your post #15

Will try this tomorrow and probably screw it up, but I'll get it.

Thanks my friend.. it's late here now almost 2 am. I'd better go to bed

Will try this tomorrow and probably screw it up, but I'll get it.

Thanks my friend.. it's late here now almost 2 am. I'd better go to bed

TopherM

Well-Known Member

Make sure over your next 2-3 brews that you take the time to calculate your actual efficiency on your new equipment using a consistent grain crush from whereever you typically buy grain (or if you mill your own). Inputting your proper average efficiency in your custom equipment profile is VITAL to most of the calculations in BeerSmith being accurate.

Once you have this equipment profile dialed in, through, BeerSmith is friggin invaluable!!

Once you have this equipment profile dialed in, through, BeerSmith is friggin invaluable!!

There is a video on the Beersmith web page that walks through setting up equipment. I have watched it a few times and am still on a trial for Beersmith. Your probably gonna be still tweaking your profile for a few batches. I am writing everything down on paper when I brew each batch and then going back after I brew and adding the recipe and tweaking equipment profiles.

Subscribed

I'm still confused by BeerSmith..

I'm still confused by BeerSmith..

If you want to make your life easier, leave trub losses at 0. Some even advocate leaving lauter dead space at 0. There is a major design flaw in BeerSmith in that is uses 'to the fermenter' efficiency as the only user efficiency input for recipe calculations. Setting losses to 0 reverts this to the more useful 'in the kettle' efficiency.I will measure the boil off and dead space tomorrow. I didn't change the number to 0 it was already set to 0 and I never edited it. I will get on it tomorrow.

As far as the wort loss to the cooler, I have a technique I use that minimizes losses going through the chiller. I've actually measured that before and there was less than a quarter of a regular pint glass. The trub loss won't be measurable until I make my next batch.

Thank you so much for your help man. If you ever make it to Georgia free beers for you my friend.

To account for post boil losses, simply increase your batch size (use the 'scaling tool' with 'keep OG, SRM, IBU' the same checked). This makes adjusting for the many things that affect losses much easier like equip mods, ingredient changes (think leaf vs. pellet), trubby grain bills, BIAB, grind changes, etc.

If you use the trub loss field in BeerSmith, whenever you change that value, you have to figure out (no tool in BeerSmith) by how much to adjust your 'to the fermenter' efficiency to get your 'to the kettle' (mash) efficiency back to normal, since that phase of brewing didn't change, only post boil losses.

Getting the right volume of wort in the kettle is the most important thing. That makes nailing your IBU, SRM, OG, etc much easier to nail. Big deal if you end up with a little more or less beer, as long as it is the style you want. The big advantage is that if you mod your gear to leave 2 liters more, or less, all you have to do is scale the batch for that. Same goes for accounting for switching from pellet to leaf hops- just scale the batch by the volume you need to compensate for. No goofy efficiency calcs to try to get your mash eff back to normal after a change to post boil volume in your system.

If you want to make your life easier, leave trub losses at 0. Some even advocate leaving lauter dead space at 0. There is a major design flaw in BeerSmith in that is uses 'to the fermenter' efficiency as the only user efficiency input for recipe calculations. Setting losses to 0 reverts this to the more useful 'in the kettle' efficiency.

To account for post boil losses, simply increase your batch size (use the 'scaling tool' with 'keep OG, SRM, IBU' the same checked). This makes adjusting for the many things that affect losses much easier like equip mods, ingredient changes (think leaf vs. pellet), trubby grain bills, BIAB, grind changes, etc.

If you use the trub loss field in BeerSmith, whenever you change that value, you have to figure out (no tool in BeerSmith) by how much to adjust your 'to the fermenter' efficiency to get your 'to the kettle' (mash) efficiency back to normal, since that phase of brewing didn't change, only post boil losses.

Getting the right volume of wort in the kettle is the most important thing. That makes nailing your IBU, SRM, OG, etc much easier to nail. Big deal if you end up with a little more or less beer, as long as it is the style you want. The big advantage is that if you mod your gear to leave 2 liters more, or less, all you have to do is scale the batch for that. Same goes for accounting for switching from pellet to leaf hops- just scale the batch by the volume you need to compensate for. No goofy efficiency calcs to try to get you mash eff back to normal for a post boil volume change.

I did some extensive Googling earlier and saw the same advice. Does this advice still apply to 2.1 or did they tweark their formulas due to feedback?

I also use a Bazooka screen as my filter instead of a falsebottom, so I assume that would mean I should go 0 on my dead space?

There is a guide that states you can switch to using trub loss in 2.0, but nothing has changed as far as I can tell, and a lot of hard core users still recommend against using trub loss in BeerSmith. I have only used 2.1, and it is still a serious pit fall if you don't watch what you are doing.I did some extensive Googling earlier and saw the same advice. Does this advice still apply to 2.1 or did they tweark their formulas due to feedback?

There is only one major flaw that is going to be addressed, and it only affects extract brewers. The problem that is the root cause of the extract issue looks like it will remain. The BeerSmith guys seem to consider it a feature, where I consider it a design flaw. I don't understand it, especially when there have to be guides on how to set up your equipment, and 3rd party online calculators to run numbers for you to get values to enter, all because of the flawed design choice they refuse to abandon. Isn't the premise of buying brewing software to have it do calcs for you? All the numbers are there for it to do it even in its flawed way, as well as the proper way if they switched.

I was the one who found the issue and reported it. I also stated my opinion on the poor design choice they made that caused the problem, and why it will still continue cause problems for all grainers. My commentary hasn't been well received, so I don't have much hope for a fix.

Are you talking MLT, or BK?I also use a Bazooka screen as my filter instead of a falsebottom, so I assume that would mean I should go 0 on my dead space?

Setting the lauter dead space to zero, when it actually isn't, may be a bit trickier to manually compensate for than setting trub loss to 0 for the BK. All you do for that is increase the batch size by the exact same amount as your losses. I know how to do it with hand calcs, but knowing if it would work to fake out BeerSmith would take some looking into the matter. That thing does some weird mojo to back into a recipe from the fermenter volume.

If you just want to know your lauter tun or boil kettle dead space, that is easy enough to figure out. Just put a couple of gallons in there, and start a siphon. Make sure you have a hose hooked to the out valve, and positioned just like brewday. Without it, the siphon will stop with much more water in the vessel than usual. Unless you don't use a hose on your valve on brewday, I guess, but you really should.

You will have to make a WAG as a prediction for your trub loss on your first brew. There are some calculators and rules of thumb out there for predicting losses to hops, both pellet and leaf, as well as break material. For an APA, I would start with increasing the batch by 1G for a pellet 10G batch, and 3G for a leaf 15G batch, that way it should result in a full batch size into the fermenter. If you have less trub loss than you predicted, just stop early. The last bit from the BK can sometimes have a lot of junk in it anyway. You could also save it and do a 'fast ferment' to check your estimated FG, but for your first brew day with new gear, things will be hectic enough as it is without adding crap.

There is a guide that states you can switch to using trub loss in 2.0, but nothing has changed as far as I can tell, and a lot of hard core users still recommend against using trub loss in BeerSmith. I have only used 2.1, and it is still a serious pit fall if you don't watch what you are doing.

There is only one major flaw that is going to be addressed, and it only affects extract brewers. The problem that is the root cause of the extract issue looks like it will remain. The BeerSmith guys seem to consider it a feature, where I consider it a design flaw. I don't understand it, especially when there have to be guides on how to set up your equipment, and 3rd party online calculators to run numbers for you to get values to enter, all because of the flawed design choice they refuse to abandon. Isn't the premise of buying brewing software to have it do calcs for you? All the numbers are there for it to do it even in its flawed way, as well as the proper way if they switched.

I was the one who found the issue and reported it. I also stated my opinion on the poor design choice they made that caused the problem, and why it will still continue cause problems for all grainers. My commentary hasn't been well received, so I don't have much hope for a fix.

Are you talking MLT, or BK?

Setting the lauter dead space to zero, when it actually isn't, may be a bit trickier to manually compensate for than setting trub loss to 0 for the BK. All you do for that is increase the batch size by the exact same amount as your losses. I know how to do it with hand calcs, but knowing if it would work to fake out BeerSmith would take some looking into the matter. That thing does some weird mojo to back into a recipe from the fermenter volume.

If you just want to know your lauter tun or boil kettle dead space, that is easy enough to figure out. Just put a couple of gallons in there, and start a siphon. Make sure you have a hose hooked to the out valve, and positioned just like brewday. Without it, the siphon will stop with much more water in the vessel than usual. Unless you don't use a hose on your valve on brewday, I guess, but you really should.

You will have to make a WAG as a prediction for your trub loss on your first brew. There are some calculators and rules of thumb out there for predicting losses to hops, both pellet and leaf, as well as break material. For an APA, I would start with increasing the batch by 1G for a pellet 10G batch, and 3G for a leaf 15G batch, that way it should result in a full batch size into the fermenter. If you have less trub loss than you predicted, just stop early. The last bit from the BK can sometimes have a lot of junk in it anyway. You could also save it and do a 'fast ferment' to check your estimated FG, but for your first brew day with new gear, things will be hectic enough as it is without adding crap.

I meant my Mash Tun. It's unfortunate the guy is stubborn about his program. That's why I prefer open source when available. When it's a team you end up with the best ideas.

Thank you for your help. You've given me much insight. I will report back with my results.

There is an open source program, BrewTarget, that is almost as complete as BeerSmith, but all in all, BeerSmith is probably better- as long as you don't use the trub loss field.That's why I prefer open source when available. When it's a team you end up with the best ideas.

The guy who created/spearheads BrewTarget is a member here, and is really open to new ideas. They are planning a rewrite of BrewTarget, and I am thinking of contributing, now that I have learned most of what I would need to know while debugging BeerSmith.

MisterTipsy

Well-Known Member

epic beersmith trub loss bitchfest thread here

http://www.beersmith.com/forum/index.php/topic,4911.0.html

http://www.beersmith.com/forum/index.php/topic,4911.0.html

What is your take on the issue?epic beersmith trub loss bitchfest thread here

http://www.beersmith.com/forum/index.php/topic,4911.0.html

I find the fanboyism over there comical. So easy to use their own words against them.

This one is good, too.

http://www.beersmith.com/forum/index.php/topic,7459.0.html

MisterTipsy

Well-Known Member

The KnowItAll guy is correct and so are you. Maybe you are the same person.

Notice how MrBeersmith remained silent on the issue. And the fanboyism over there is funny. hahaha!

The trub flaw doesn't prevent me from using the software. The beer tastes good and it finishes just like Beersmith says it should, so I have no real complaints about Beersmith.

Notice how MrBeersmith remained silent on the issue. And the fanboyism over there is funny. hahaha!

The trub flaw doesn't prevent me from using the software. The beer tastes good and it finishes just like Beersmith says it should, so I have no real complaints about Beersmith.

Similar threads

- Replies

- 32

- Views

- 2K

- Replies

- 2

- Views

- 447

- Replies

- 48

- Views

- 3K