MaxOut

Well-Known Member

Thank you Whutever I'm humbled by all the nice words.

cowgo said:Can you post pics of your entire garage to include the kitchen dining area? Your next build has to be a garage bar with all the bling.

225 said:What did you use for the electronic gas valves?

Honeywell SmartValves. I used the ones with intermittent hot surface ignition and standing pilot. I like these because they do not require a separate ignition module. I could supply you with the part numbers of the ones I used if you are interested.

BrewHobby1 said:Maxout, amazing system!

I am in the market for starting a build and I just go from an awesome build to an unbelievably more awesome build. I feel like a honey bee that doesn't know where to stop. All of you creative people are killing me. I hate all of you. Now I will have to go take a welding class. Cr*p! Oh wait, the things I could try to make! My wife is gonna kill me.

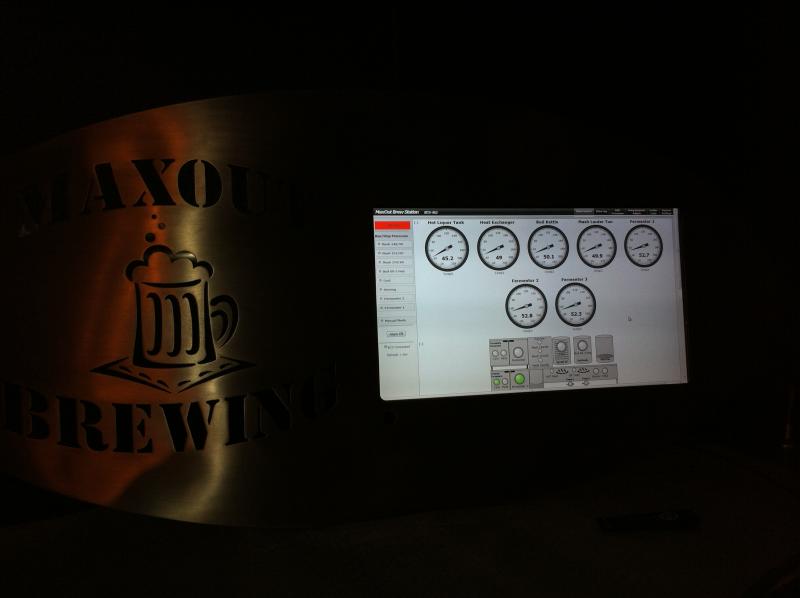

MaxOut said:I wanted to clear the working counter and decided to upgrade the 19” computer screen and get it off the counter. I went wireless with the keyboard and mouse and made a custom stainless sign to house the new 32” LED screen and custom lighted sign. Here is a few build shots of the sign and installation.

HopsJunkie said:Seriously, I hope you got a good deal on that steam kettle cause holy crap those things are expensive. I speak from kitchen experience on that one.

MaxOut said:Found it on Craigslist advertised as the ultimate crab cooker. The add said it was 30 gallon and turned out to be 60. Was originally jetted for natural gas but the guy had it re jetted for propane so he could run it on portable tanks. He said it would cut off and needed a thermocouple. I drove two hours and bought it on the spot. I paid $350.00 for the kettle and another $50.00 for the heavy duty stir paddle. Turns out whoever re jetted it did not adjust the air on the eight burners. I adjusted the air and plumbed it in to my existing propane supply and I was good to go. I put steel heavy duty casters on it a new power cord, new dump valve, sight glass, camlocks on lid, mounting plate and a good cleaning. Total I have about $800.00 in it. To buy the kettle new is over $18K. More than I was looking to spend for a larger boil kettle but compared to a 55 gallon Blichman it's a good buy with its own heat source. Win Win

Brew-ta-sauraus said:What do you think in total $ you have into that Brewery?

BrewHobby1 said:Okay.....WOW!

Another fine example of a mix of insanity, money, and time.

Da%n! I hope you give tours. I might stop by.

Great logo. Not that you should go over the top on this build but that sign would look sick with flames (real or on an LCD) behind the letters and beer mug. I'll just throw that out.Wanted to have the kegs private labeled and made a few extra to label the other equipment. Made from stainless on a plasma table and backed with the black FRP board for contrast.

Beernip said:Great logo. Not that you should go over the top on this build but that sign would look sick with flames (real or on an LCD) behind the letters and beer mug. I'll just throw that out.

Unbelievable build man!

chairbornrangerx said:Truly inspirational! Amazing build for sure

I just picked up a Stainless 3 basin 8ft long sink myself on Saturday for part of my home brewery build. So many ideas I could take from this thread!

I raise my glass to you sir

Man!....I've got a long way to go. Sweet brewery. I like the utility cart you have setup.

Enter your email address to join: