You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Blichmann Therminator vs.....

- Thread starter archer75

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Golddiggie

Well-Known Member

i don't think there is any difference between plate chillers of the same size besides brand name and price. on blichmann's website they compare apples to oranges to show how their chiller is better it would be more useful for them to compare chillers of the same size.

Golddiggie

Well-Known Member

i don't think there is any difference between plate chillers of the same size besides brand name and price. on blichmann's website they compare apples to oranges to show how their chiller is better it would be more useful for them to compare chillers of the same size.

But that would be fair.

Golddiggie

Well-Known Member

With shipping the DD chiller is only $10 less than the blichmann for me. Does it perform better? Or are they both about the same?

The one I linked to is 1-1/2 times the size of the Blichmann. I easily chill ~7 gallons of wort (closer to 7-1/2) to under 60F in maybe 10 minutes (cooler and faster in the winter, takes a little longer in the summer, due to chill water temps). IMO/IME, all 40 plate chillers of the same size will chill in pretty much the same amount of time. Once you get longer/larger plates, your chill time goes down fast. That's why the 20 plate large chiller (most common is the Shirron) can perform pretty close to a smaller shaped 40 plate chiller. Duda Diesel has a chart on their site to help you figure things out. A lot also depends on the speed the wort it going through the chiller, as well as flow rate of the chill water. Dialing in that goes a long way to getting better chill times.

Keep in mind, most places also only give time frames to get to 75F. NOT down to where many of us go to pitch. The last few degrees are the hardest to reach, often taking longer (if not as long as) than it took to get to ~100F (from boil).

Something else to remember. With plate chillers, the chill water feed hose diameter has a large impact on the chill time. Go with either a 5/8" or 3/4" ID hose there.

Golddiggie

Well-Known Member

The DD has an option for male NPT for the wort or barbs welded on. The barbs seem like the way to go for me. Preference either way?

I went with the NPT fittings. That way I could use QD's on mine and not worry. With barbs, you'll probably want to use clamps on them, which adds another layer of complexity to the system. With the NPT fittings you could use barb fittings later, if you really want to. I'd rather be more flexible than less... What happens if in a year, or two, you decide you want to use QD's on everything? With that chiller, you won't be able to. If you get the one with the NPT fittings, you can just change the barbs over to whatever QD you get.

archer75

Well-Known Member

One more question, I plan on running this out of my BK into a blichmann hop rocket, then to the DD and then the fermenter. Somewhere in this line I was going to install a pump to move the wort. Where should the pump be placed in this setup?

My BK sits on a blichmann burner with the leg extensions so it's a couple feet off the ground but not enough to gravity feed everything in the flow, thus the pump. Should I bother to put ball valves on the pump to control the flow? The kettle does have a ball valve on it.

My BK sits on a blichmann burner with the leg extensions so it's a couple feet off the ground but not enough to gravity feed everything in the flow, thus the pump. Should I bother to put ball valves on the pump to control the flow? The kettle does have a ball valve on it.

I run a hop rocket to CFC. You'll want your pump between the kettle and hop rocket. You'll also want a ball valve on the outlet of the pump. You don't want to restrict flow TO the pump as it will impede its performance.

Golddiggie

Well-Known Member

One more question, I plan on running this out of my BK into a blichmann hop rocket, then to the DD and then the fermenter. Somewhere in this line I was going to install a pump to move the wort. Where should the pump be placed in this setup?

Put it right after the kettle.

YES!!! Triple YES if you plan to run boiling hot wort through to sanitize (only needs 30-60 seconds at over 200F to be sanitized).My BK sits on a blichmann burner with the leg extensions so it's a couple feet off the ground but not enough to gravity feed everything in the flow, thus the pump. Should I bother to put ball valves on the pump to control the flow?

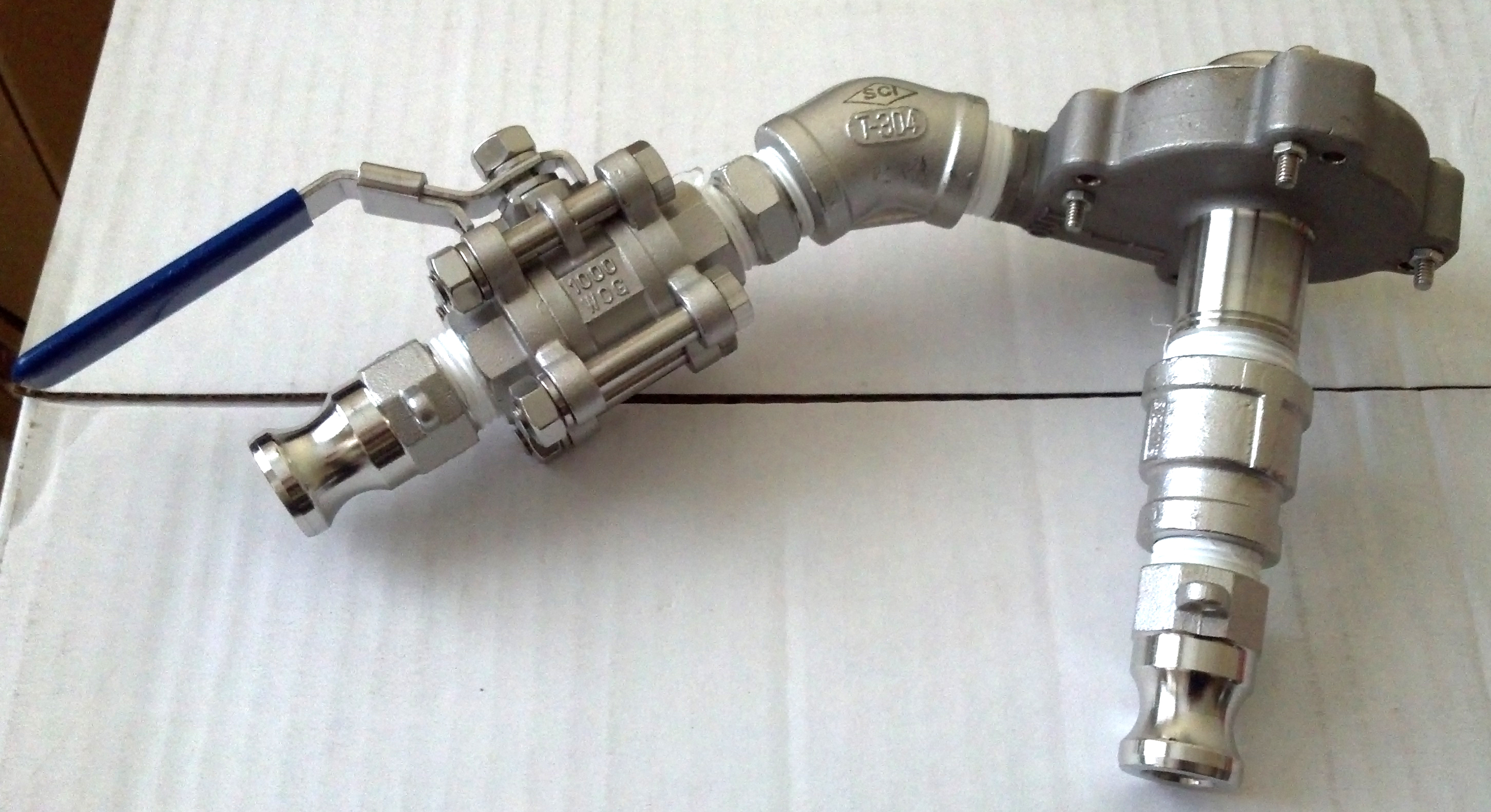

That only makes it easier to connect things up. I would also plan to make a recirculation setup. Basically, you run the boiling hot wort through the chiller, back into the kettle for a while. Then you start the chill water feed to get the temperature down. You can add the hop rocket whenever you want after the chiller is sanitized. Or even add it during the boil (not used one, probably never will at home). Once you hit a good level recirculating the wort (with the chill water going) you kick the output from the chiller over to the fermenting vessel. I do this with an attachment on the plate chiller. It has two valves (and a thermometer fitting) so that I can simply change where the wort is flowing. Turn off the pump, close one valve and open the other. Easy as pie.The kettle does have a ball valve on it.

My pump head:

Similar threads

- Replies

- 5

- Views

- 776

- Replies

- 0

- Views

- 309

- Replies

- 6

- Views

- 1K

- Replies

- 0

- Views

- 577