After 2 weeks I finally got my power quote done, it is scheduled to be installed next Saturday. I will have a 50 amp (GFCI) sub panel in my brewing area that will house a 240 volt 30 amp circuit, and a 120 volt 20 amp circuit. Thanks to a lot of helpful advise I got in here I was able to get this first step accomplished.

My next step is to electrify my stainless steel 9 gallon Bayou Classic kettle. I am going to use it to heat the strike water for my 10 gallon Igloo cooler MLT. And I am also going to use it for my boil kettle as well.

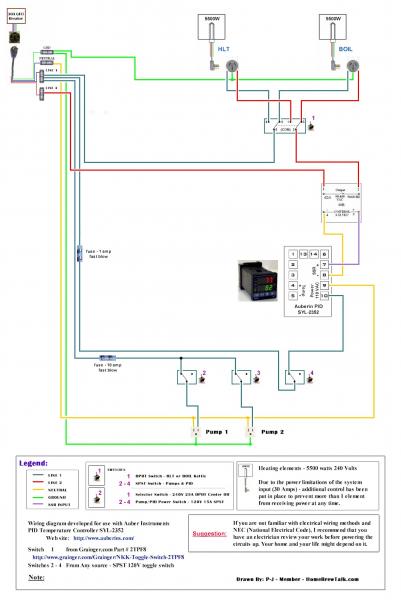

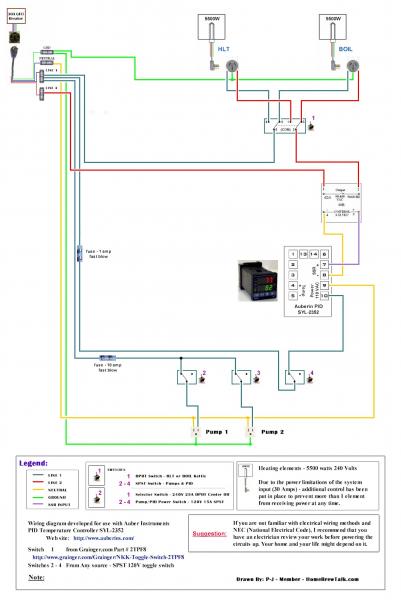

Basically I am going to use a 5500 watt element controlled by an Auber 2352 PID. I am going to use a modified (one element, and no pumps) version of the attached wiring diagram from P-J.

I believe that this should be a simple first step into the world of electric brewing. If I can successfully take this first step and be able to brew beer without propane and all the associated carbon monoxide dangers I'll be pretty happy. That way I can brew beer as I take my time and work on building a nice dual element/dual pump control box system.

So if anyone has any advise or any tips on this next step I would appreciate hearing it. Thanks!

My next step is to electrify my stainless steel 9 gallon Bayou Classic kettle. I am going to use it to heat the strike water for my 10 gallon Igloo cooler MLT. And I am also going to use it for my boil kettle as well.

Basically I am going to use a 5500 watt element controlled by an Auber 2352 PID. I am going to use a modified (one element, and no pumps) version of the attached wiring diagram from P-J.

I believe that this should be a simple first step into the world of electric brewing. If I can successfully take this first step and be able to brew beer without propane and all the associated carbon monoxide dangers I'll be pretty happy. That way I can brew beer as I take my time and work on building a nice dual element/dual pump control box system.

So if anyone has any advise or any tips on this next step I would appreciate hearing it. Thanks!