JonClayton

Well-Known Member

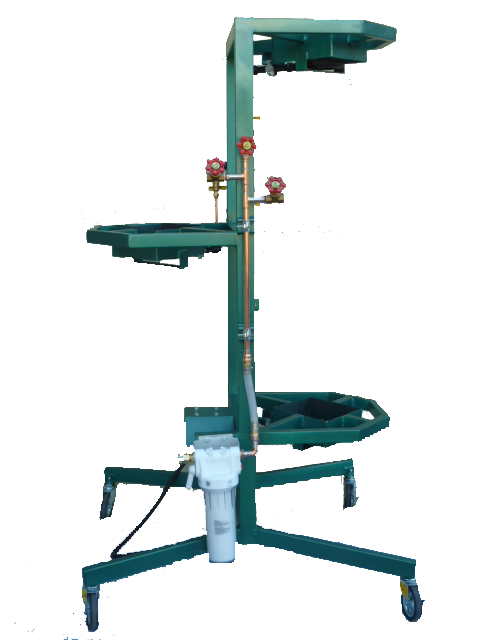

I have decided to have a stand built using desertbrews's plans posted here by lil'sparky https://www.homebrewtalk.com/f11/3-tier-tree-sculpture-plans-27324/

Eventually, I would one day like to automate the temp control on system with some sort of pid or similar control, but for now I think I will just do the stand and natural gas burners.

Question: If in the future I wanted to add temperature automation, am I wasting a lot of time/energy just making the functional brew stand first? What is the easiest way to add the temp control? All that I really want to be able to do it tell the system maintain the hlt at 170, maintain mash at 155 etc and have it control the burners to do so.

The system that I've seen used some sort of part taken off at gas hot water heater to control the burner and some sort of PID to control that part, but it was a bit over my head

Eventually, I would one day like to automate the temp control on system with some sort of pid or similar control, but for now I think I will just do the stand and natural gas burners.

Question: If in the future I wanted to add temperature automation, am I wasting a lot of time/energy just making the functional brew stand first? What is the easiest way to add the temp control? All that I really want to be able to do it tell the system maintain the hlt at 170, maintain mash at 155 etc and have it control the burners to do so.

The system that I've seen used some sort of part taken off at gas hot water heater to control the burner and some sort of PID to control that part, but it was a bit over my head