kuenro02

Well-Known Member

I heard that some guys use there herms coil as there wort chiller. Does anyone have pictures, sketchup, or explaination of how to do this? Thanks

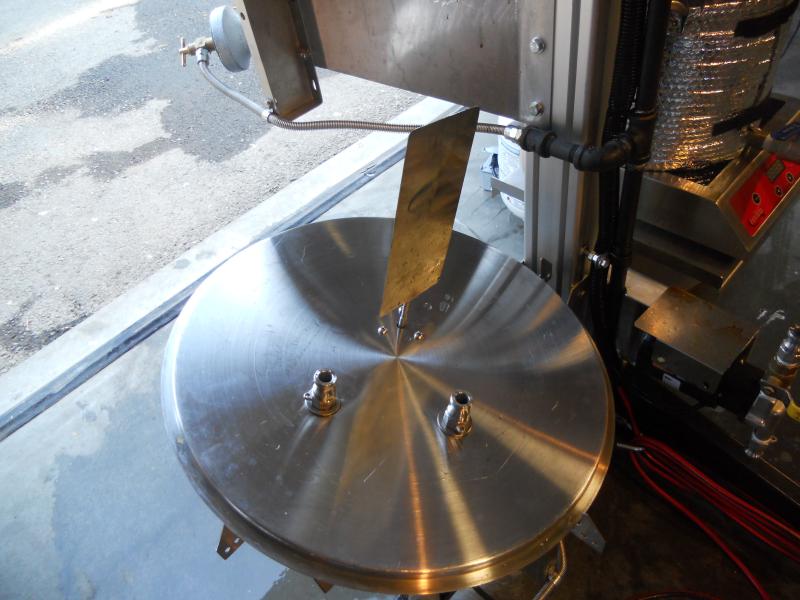

Mine is attached to the lid with cam lock quick connects. It consists of two coils, one inside the other working in parallel.I heard that some guys use there herms coil as there wort chiller. Does anyone have pictures, sketchup, or explaination of how to do this? Thanks

Why did you go with 2 coils? Just for more surface area? Then you can have it in your HLT for your herms coil and then you put it in your BK to run cool water through it? How did you connect your 2 coils? Thanks

I started with a 70' coil and it was too slow. I cut it half and made two 35' coils.

I use it as a HERMS and then move the lid to the BK for an immersion chiller.

I connected them with standard copper fittings. One coil delivers water to the bottom of the coil first and the other to the top first. They are manifolded into two 1/2' copper pipes, then into the quick connects. They really work well. From boil to 65 degrees in fifteen minutes with the motor spinning the paddle.

I have heard others bragging about the same chilling time, but mine really does it.

The two 3/8" coils are connected into the two 1/2" copper pipes. You can see the 90degree elbows on the bottom. On the top side (hidden from the photo) are two "Tees" that the top end of the coils are attached. One of the 1/2" pipes feeds in and the other drains out.I only see 2 water lines? Where are the other two?

The two 3/8" coils are connected into the two 1/2" copper pipes. You can see the 90degree elbows on the bottom. On the top side (hidden from the photo) are two "Tees" that the top end of the coils are attached. One of the 1/2" pipes feeds in and the other drains out.

Makes sense, I was confused how you had them hooked up from the pictures. Thanks!:rockin:

On second thought, is your hot water and your cold water side by side on the bottom of the coil? Aren't you just swapping BTU's from each other? Wouldn't it be better to have the cold go in the bottom and out the top of the coil? I suppose the agitation makes that a moot point?

Mine is attached to the lid with cam lock quick connects. It consists of two coils, one inside the other working in parallel.

It has a gear reduction motor on the lid attached to a stainless steel paddle to circulate the wort. It works good.

Enter your email address to join: