Update: after I placed my order there was a note placed by the company stating that the piece I ordered was not the best piece for my unit (based on the serial number I provided). They replaced my order with what True recommended. The new part was $10 cheaper too. A+ for customer service.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

True TDD-2 Kegerator remodel/touchup

- Thread starter kchomebrew

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

t_d_harvey

Member

- Joined

- May 20, 2014

- Messages

- 15

- Reaction score

- 5

Nice Mikey! Great set-up Phillip.

I will say the evaporation pan does work great unless you have installed the Kegerators under a bar top as I did...big no no on my part. Not enough air circulation for the rear vents resulting in an over filled evaporation pan! If anyone has any suggestions on a work around so I can use the pan, it would be greatly appreciated. I have the unit out right now and would be a great time to do some work.

Btw Phillip, so jealous of your taps! Exact setup I want to get to, going to have some strong convincing to the wife to get it done.

Here is my set-up, don't have a picture of the keg side, but you get the idea. Bar is rock faced and the keg sits in a spot under the bar that has about 6" on either side. Also it is the Tdd-3:

I will say the evaporation pan does work great unless you have installed the Kegerators under a bar top as I did...big no no on my part. Not enough air circulation for the rear vents resulting in an over filled evaporation pan! If anyone has any suggestions on a work around so I can use the pan, it would be greatly appreciated. I have the unit out right now and would be a great time to do some work.

Btw Phillip, so jealous of your taps! Exact setup I want to get to, going to have some strong convincing to the wife to get it done.

Here is my set-up, don't have a picture of the keg side, but you get the idea. Bar is rock faced and the keg sits in a spot under the bar that has about 6" on either side. Also it is the Tdd-3:

shadowpaige64507

Active Member

MikeyA,

I've experienced what your talking about with the ice at the bottom. In my case I have a slow freon leak and when the system gets low it runs the compressor more and creates excess water and lots of ice. Even freezing some of my yeast bank. I would recommend having the freon level checked.

I've experienced what your talking about with the ice at the bottom. In my case I have a slow freon leak and when the system gets low it runs the compressor more and creates excess water and lots of ice. Even freezing some of my yeast bank. I would recommend having the freon level checked.

philipCT

Brewniversity student

- Joined

- May 10, 2013

- Messages

- 771

- Reaction score

- 171

Nice Mikey! Great set-up Phillip.

...

Btw Phillip, so jealous of your taps! Exact setup I want to get to, going to have some strong convincing to the wife to get it done.

Here is my set-up, don't have a picture of the keg side, but you get the idea. Bar is rock faced and the keg sits in a spot under the bar that has about 6" on either side. Also it is the Tdd-3:

Hah! I have to say that is a fine looking setup too. I love the stone. My plan is to build a bar around my kegerator too - I just haven't gotten there yet!

The TDD-2 has a condenser vent on the back side of the unit. I plan to build in a vent in the bar structure so as not to block that airflow.

t_d_harvey

Member

- Joined

- May 20, 2014

- Messages

- 15

- Reaction score

- 5

Yea, would be highly suggested. Wish I would have thought of that when I built mine. Would b a pain to do it now, but maybe one day I can get it done.

Thanks btw! I got stone every where in my house. Lol. Luckily I know a guy that owns a stone yard...below is my kitchen.

Thanks btw! I got stone every where in my house. Lol. Luckily I know a guy that owns a stone yard...below is my kitchen.

Ok...I finally got my replacement piece from True. Starting to dig into this project, I fee like it's going to be a little more involved than I realized. How were you guys able to access the screws to remove the fan? Once I get that disconnected, do I just pull out the cold air tubes?

philipCT

Brewniversity student

- Joined

- May 10, 2013

- Messages

- 771

- Reaction score

- 171

Yeah, I hate working on these things.

You just yanked and jimmy and inch those tubes right outta there. The screws are a *****. I bought a hex nut bit for my drill but I also needed a hand tool to access some of those screws.

For what it's worth, you probably only need to replace that bottom pan piece so you may consider leaving the bigger piece that's attached to the roof of the box right where it is and just replace the pan part. They are totally separate.

Good luck. You will earn your homebrew tonight.

You just yanked and jimmy and inch those tubes right outta there. The screws are a *****. I bought a hex nut bit for my drill but I also needed a hand tool to access some of those screws.

For what it's worth, you probably only need to replace that bottom pan piece so you may consider leaving the bigger piece that's attached to the roof of the box right where it is and just replace the pan part. They are totally separate.

Good luck. You will earn your homebrew tonight.

I'm having a hell of a time getting he old evap pan off. Probably because it's been stuck on for the last 23 years. I noticed two wires (one black, one white) that runs through the back, left corner of the evap pan. Do these wires go to the fan? I can't tell without taking apart a bunch of stuff I don't wanna talk apart if I don't have to. If they don't go to the fan, I'll just cut them and not worry about trying to disconnect them and run them through the new evap pan.

philipCT

Brewniversity student

- Joined

- May 10, 2013

- Messages

- 771

- Reaction score

- 171

Very likely those wires feed the fan and the light. On mine they were joined with some wiring nuts and strapped down to the topside of the fan mounting plate. You probably don't want to cut those. Here are some shots of what my wiring looked like. And yes, I replaced those hoses, as ridiculously expensive as the replacement parts were.

Are you trying to remove the entire pan or just the bottom part? Only the bottom part is the culprit in this story - that's where the leaks are. As long as you get all the screws out, that should come out with a little convincing. Getting the new one back on will be the tough part because it's got to fit back into the gasket.

I know it's tight in there, but do you have any photos?

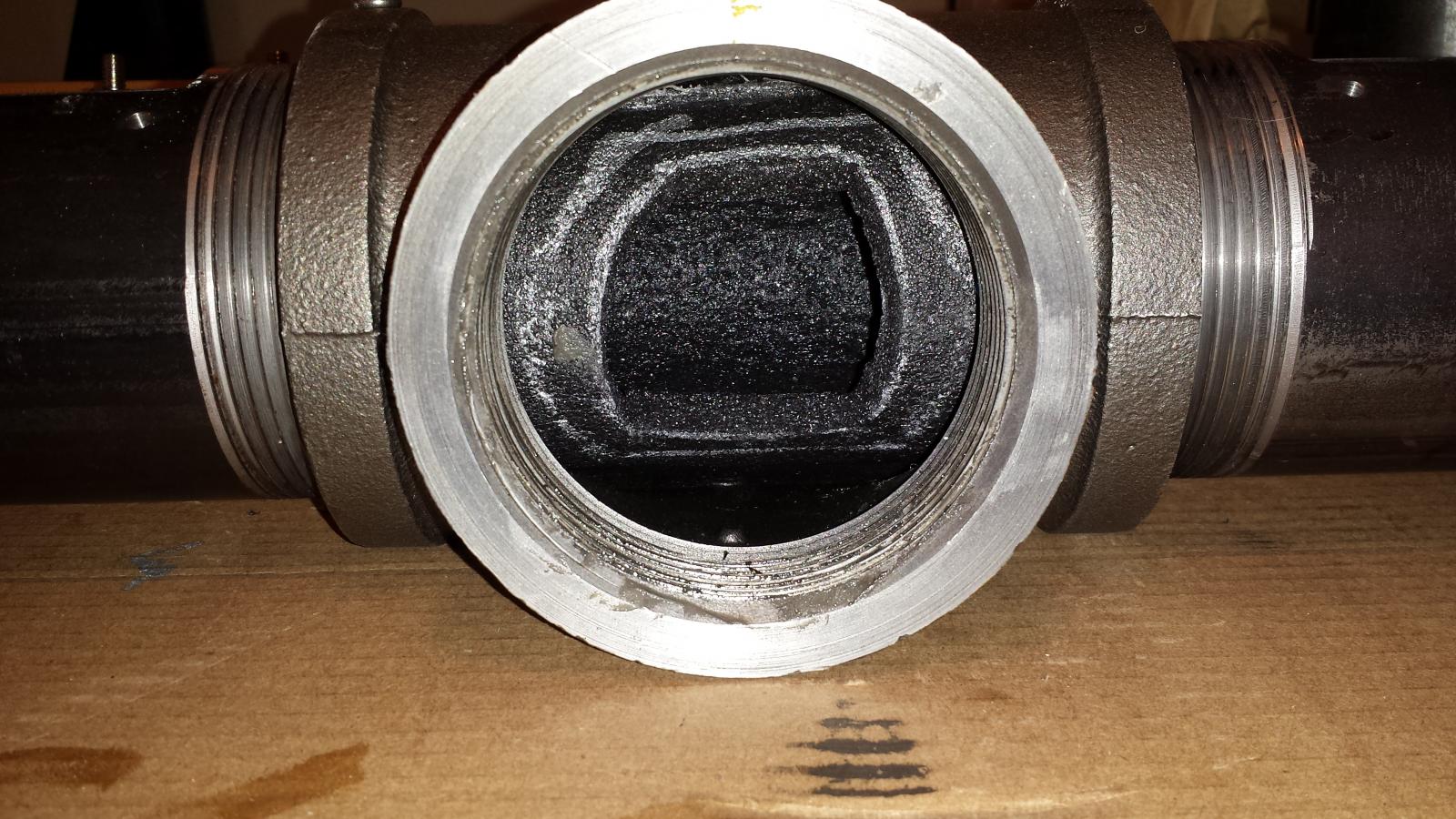

And for yucks, here's a shot of the gas tube racks I put in at the back of the kegerator.

Are you trying to remove the entire pan or just the bottom part? Only the bottom part is the culprit in this story - that's where the leaks are. As long as you get all the screws out, that should come out with a little convincing. Getting the new one back on will be the tough part because it's got to fit back into the gasket.

I know it's tight in there, but do you have any photos?

And for yucks, here's a shot of the gas tube racks I put in at the back of the kegerator.

So.....I finally re-read your original post and realized that you said to just replace the bottom pan....that's what I'm going to do now. Sorry for not listening the first time (maybe my wife is right about me not listening??? Lol)

jasonvincent

New Member

- Joined

- Jan 27, 2013

- Messages

- 1

- Reaction score

- 0

I've recently acquired a TDD-3 from my father-in-law. It is awesome as is this post for tips on working on them. My evap pan is leaking, so I have a project in my future.

Questions about your tap tower upgrade, what did you use to insulate the inside of the tower? Do you experience any condensation? Do you hang your hoses at the top of the vertical sections of the tower, or try to extend them into the horizontal section?

Questions about your tap tower upgrade, what did you use to insulate the inside of the tower? Do you experience any condensation? Do you hang your hoses at the top of the vertical sections of the tower, or try to extend them into the horizontal section?

lonerunman

Member

Questions about your tap tower upgrade, what did you use to insulate the inside of the tower? Do you experience any condensation? Do you hang your hoses at the top of the vertical sections of the tower, or try to extend them into the horizontal section?

Hi Jason - I insulated my tower with some spare blue camping sleeping pad that I had kicking around. It's that cheap pad that most outdoorsy stores sell, but you could use any similar closed-cell foam you find.

After installing my shanks, tailpieces and lines, I cut the foam to length and with enough width to wrap inside the tower. I was able to shove the foam up the length of the tower since it was stiff enough. Voila!

As for the cap, I jammed some bubble wrap into the top of the tower, trying to get it down and around the tailpiece, then popped the cap back on. I'm a little tight for space in there because I doubled up my taps (it came with one tap per tower, and I added a second tap to each - yeah!).

Overall it works pretty well, but I do get a bit of condensation around the shanks and at the bottom of the towers where they are mounted into the fridge unit. I guess there's not much/any insulation at these points.

But most importantly, the beer flows out fine without foaming

Hope that helps. What have others done to insulate their towers?

Bruce

p.s. what an awesome fridge, isn't it? Mine's an old renovation recovery as well - it was going to the landfill but all it needed was a serious cleanup and a new fan. I still need some new door seals, but dang they're spendy!

philipCT

Brewniversity student

- Joined

- May 10, 2013

- Messages

- 771

- Reaction score

- 171

...

Questions about your tap tower upgrade, what did you use to insulate the inside of the tower? Do you experience any condensation? Do you hang your hoses at the top of the vertical sections of the tower, or try to extend them into the horizontal section?

Well good luck with that evap pan repair!

re: insulation - I found cylinders of closed cell foam that were about 2" in diameter. I did a fair amount of cutting and gluing to make several pieces that fit nice and tight around everything. Hope these pics help but LMK if you have any questions.

I don't get any condensation on the pipes. They are definitely cold to the touch though.

Here's what I ordered from Zoro:

Zoro Item Product Name Description Shipping Unit Price Qty. Amount

G1242552 Closed Cell Pipe Insulation Pipe Insulation,2 In. ID,6 ft. L,Black Expedited Shipping Available $4.07 2 $8.14

Subtotal $8.14

Shipping $5.00

Tax $0.84

Total $13.98

bdawgbrewer

New Member

- Joined

- Aug 15, 2019

- Messages

- 2

- Reaction score

- 0

k

Going to bring this convo back almost 10 years later... I have a TDD-1 that I also have to replace the evap tray. For those who did this, did you end up using any kind of rubberized spray (sealant) to the tray for longevity or was it unnecessary?

Also, have any of you had to deal with any kind of acetone smell coming from the fridge? I get a whiff sometimes when I walk by it. It isn't a refrigerant leak, so I'm not 100% sure what it is. My old man thinks it might be the compressor heating up old paint or glue, or possibly dust. There is also plumber's putty it seems holding two sheet metal pieces to separate wires around the evaporator fan and they do rest on the coil, so maybe it's that stuff heating up?

Any help would be appreciated if any of you guys are still around! Thanks!

Also, have any of you had to deal with any kind of acetone smell coming from the fridge? I get a whiff sometimes when I walk by it. It isn't a refrigerant leak, so I'm not 100% sure what it is. My old man thinks it might be the compressor heating up old paint or glue, or possibly dust. There is also plumber's putty it seems holding two sheet metal pieces to separate wires around the evaporator fan and they do rest on the coil, so maybe it's that stuff heating up?

Any help would be appreciated if any of you guys are still around! Thanks!

Last edited:

Similar threads

- Replies

- 15

- Views

- 874