planker101

Well-Known Member

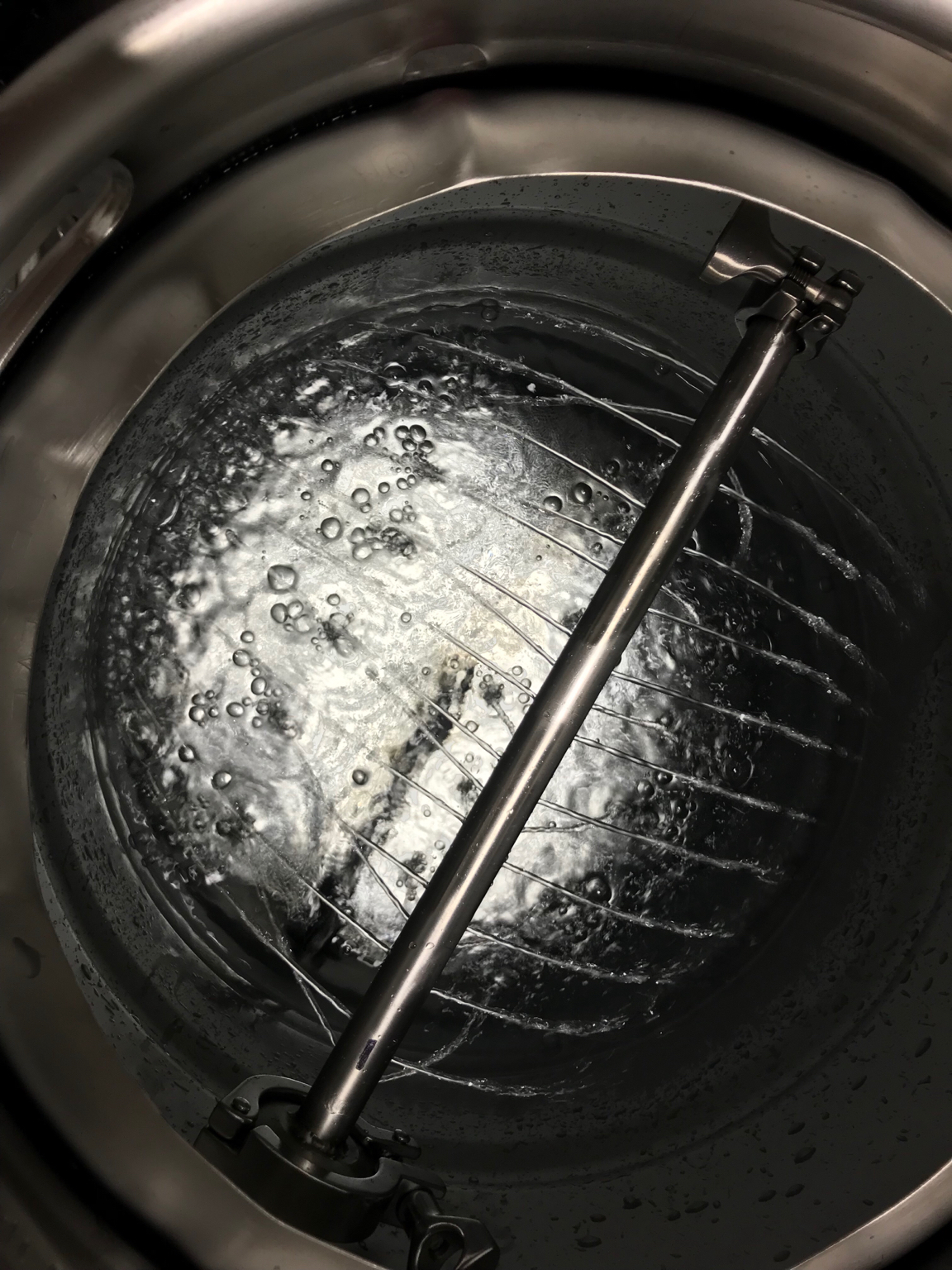

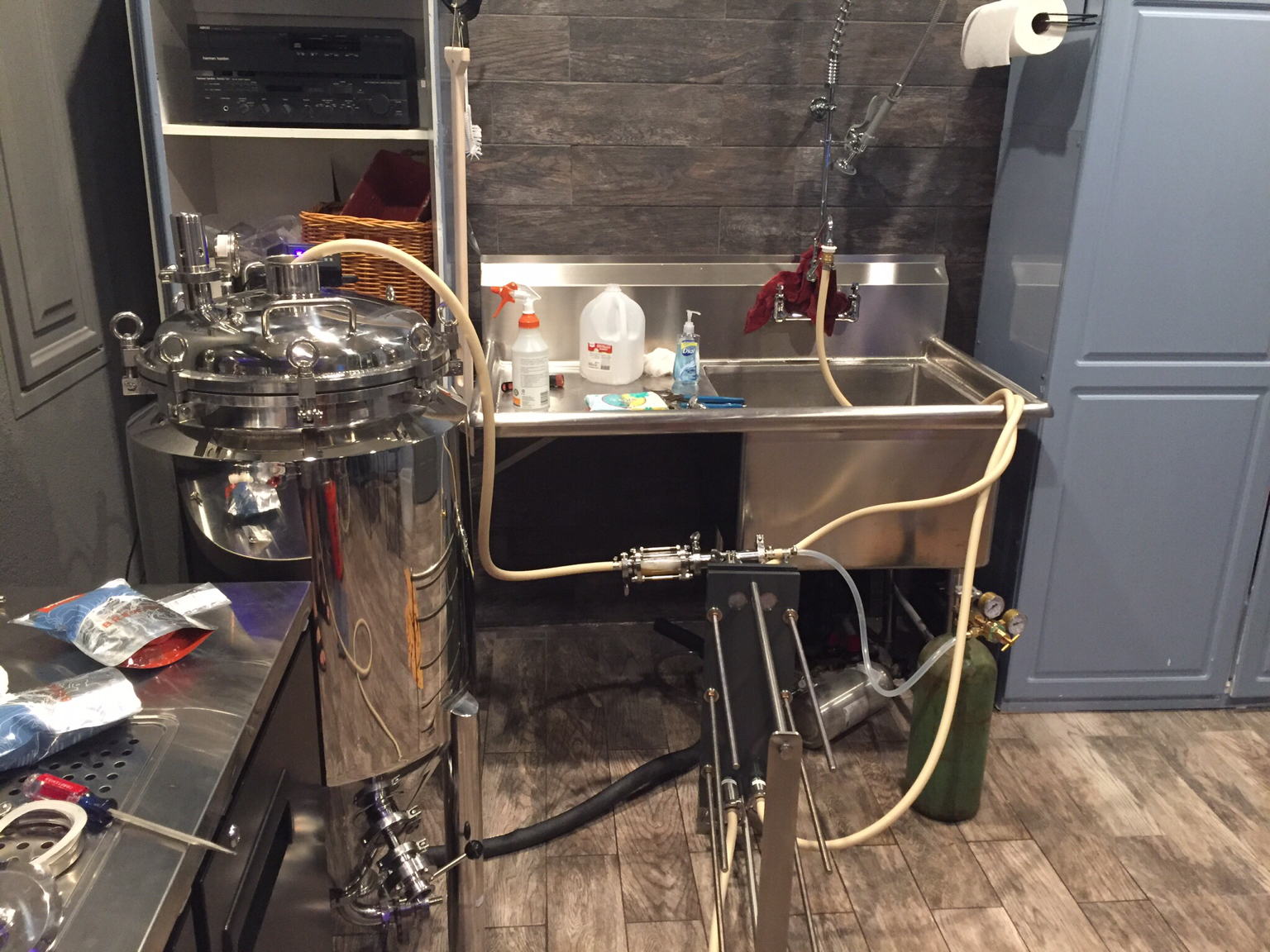

Just when I think I've seen it all!

That looks pretty amazing. Have you brewed on it yet?

Yeah, did a test batch to make sure it worked and it does. I actually preferred it to my overly expensive BIAB setup I built. I sell stands on occasion though and will have to remake the breWheel in stainless and with a few asthetic mods if I am going to keep it at the house.