aboantopick

Well-Known Member

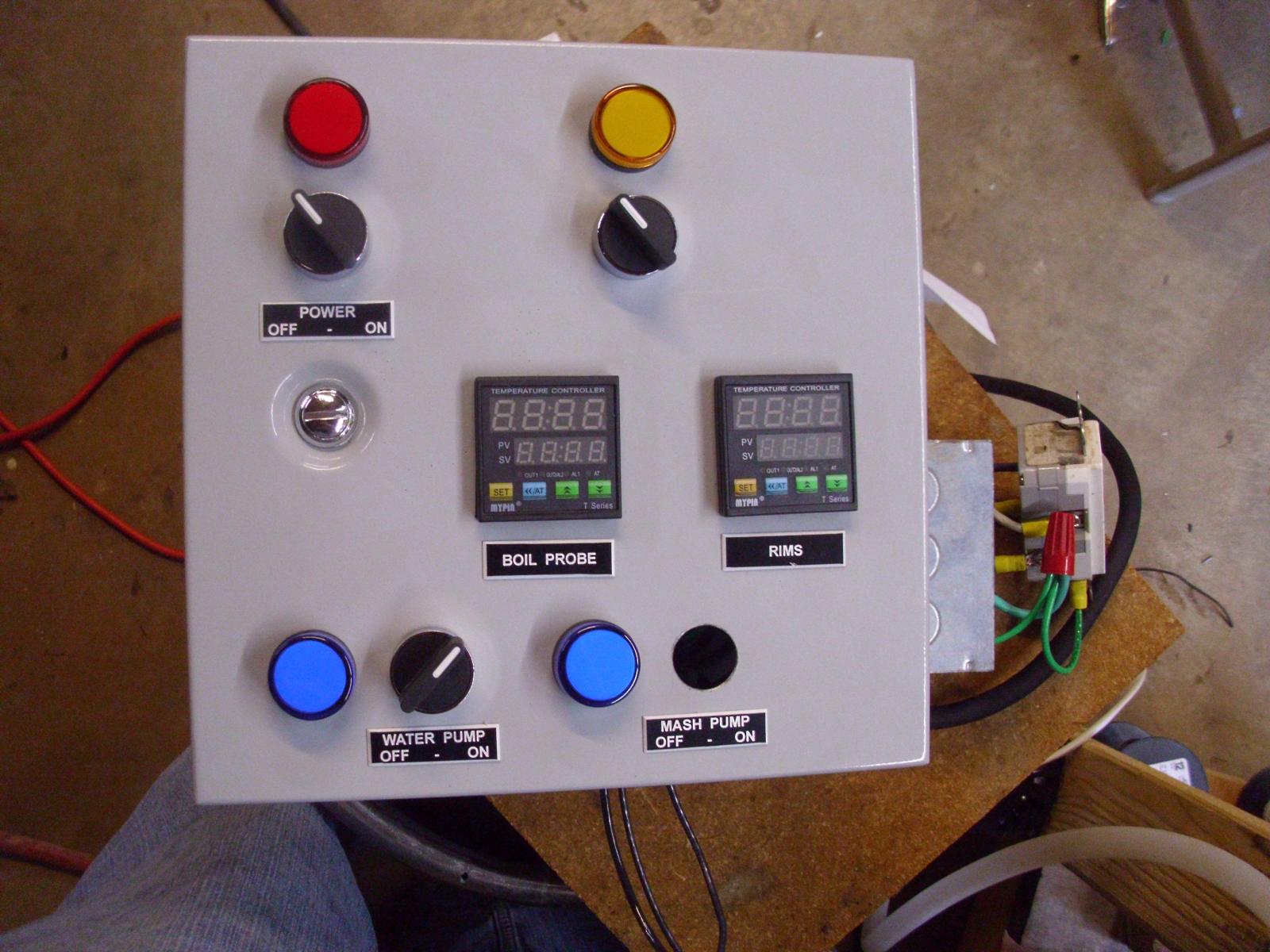

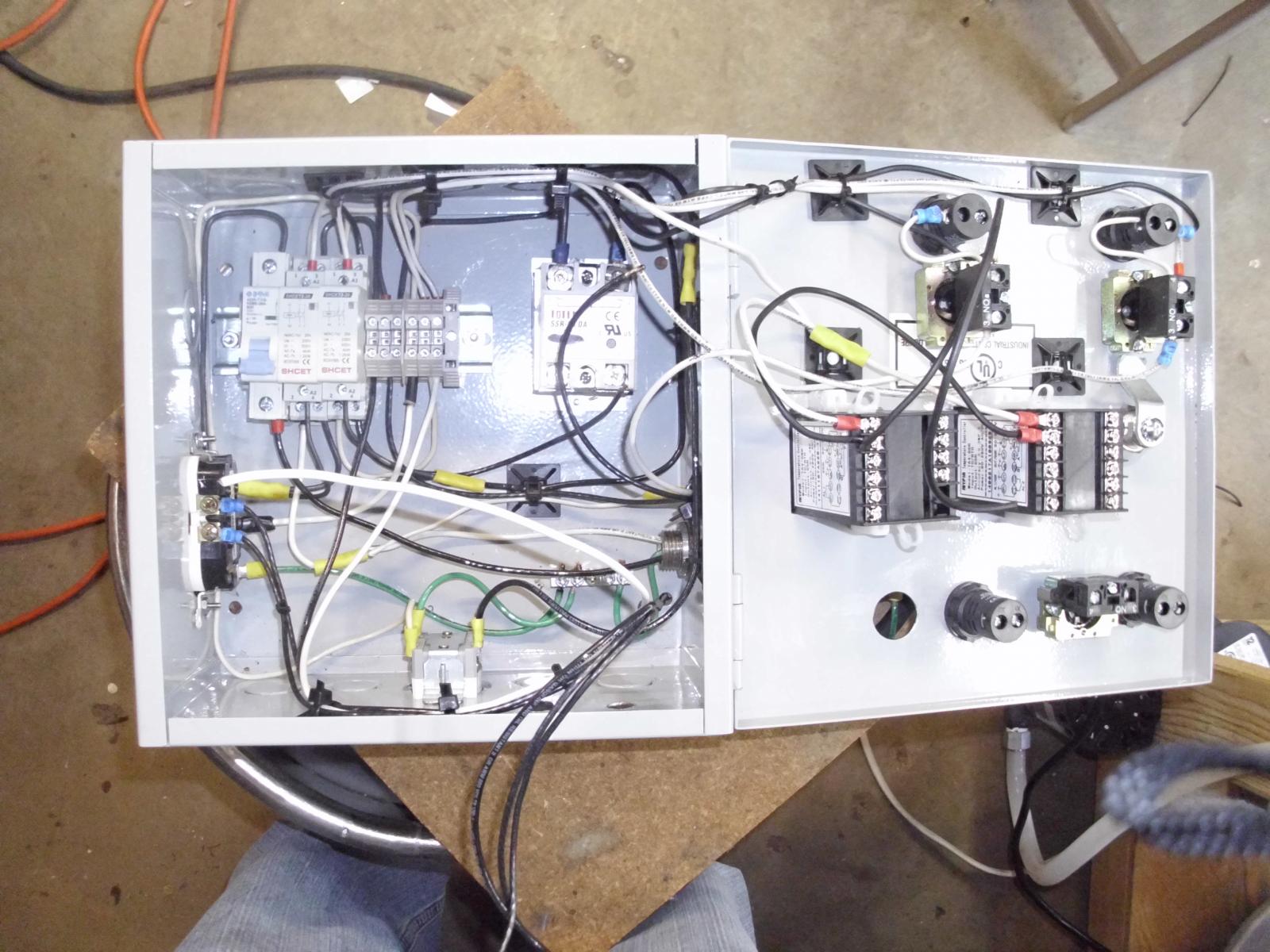

This is my brewery as created last year. I started to add a HERMS to keep my mash water up to temp and generally improve my brewery. After much planning I decided on a 2000W RIMS system and keep my Propane BK. My mash tun was going to stay a 10 gl cooler but decided to sell it and convert a 15.5 kegger.

I will post pics as I go along hoping someone ran into the same issues I may have.

I got news today that the 1-1/2"x8" SS pipe I ordered from Zorro for 20 bucks is not coming until 3-31-15.

I will post pics as I go along hoping someone ran into the same issues I may have.

I got news today that the 1-1/2"x8" SS pipe I ordered from Zorro for 20 bucks is not coming until 3-31-15.