I don't have a valve setup yet??? Do I need a 2in long 1/2in nipple made of brass, stainless, galvanized??? Does my valve need to be stainless, brass?

Already failed once at Home Depot...

Sent from my iPhone using Home Brew

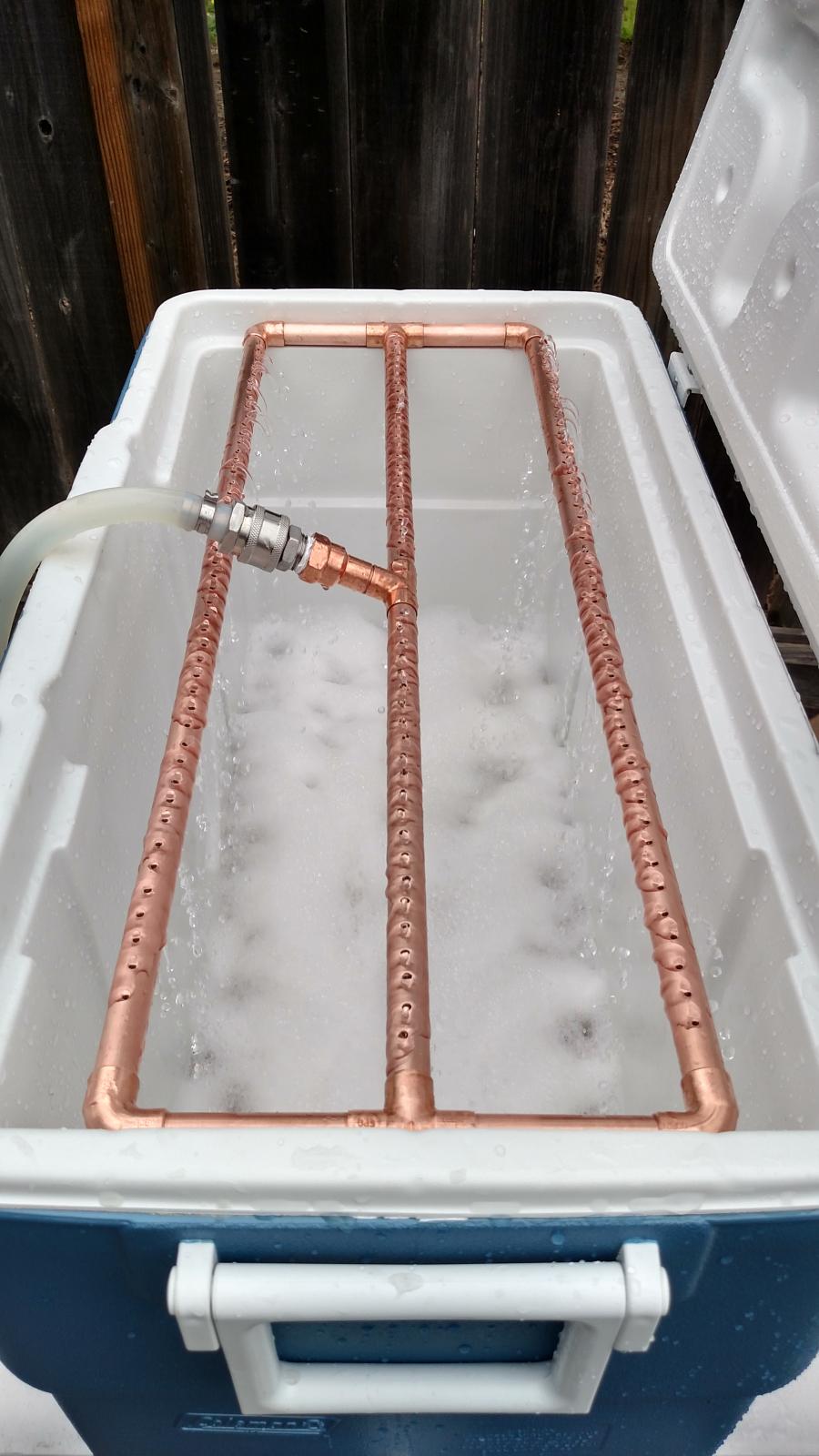

It appears that I used a 1 1/2" long threaded on each end pipe. I also reused the cooler's plastic seal. looks a little dirty in the picture. Note the 4 washers needed for standing off the cooler. If I recall, those are SS washers, and I bought them at Fastenal because they are the only ones who sell SS with the correct inside diameter. The rest is brass or copper in my setup.

I've stood for many hours in that HD isle. I know what you're talking about, but that's why it's called DIY.