Got a buddy with a small brewery across town who wants to make a batch of this for a 500L Belgian quad. Anybody have any tips or tricks for doing this on a larger scale? I'm mostly wondering about heat: should he run a bigger flame to heat a greater volume, or will he risk scorching the sugar or getting it to a boil before it's all dissolved that way?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

20 lb of sugar and a jar of yeast nutrient

- Thread starter SnickASaurusRex

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Got a buddy with a small brewery across town who wants to make a batch of this for a 500L Belgian quad. Anybody have any tips or tricks for doing this on a larger scale? I'm mostly wondering about heat: should he run a bigger flame to heat a greater volume, or will he risk scorching the sugar or getting it to a boil before it's all dissolved that way?

He definitely should gain experience with sugar syrups by doing a few small batches of say 1-5 pounds progressively, so he can get a feel for what happens and what to look out and watch for. Thick bottomed pots help to diffuse heat and an accurate thermometer is paramount.

Temperature is key, so having some cold water ready to add to the bubbly sugar mixture is essential. While adding heat, evaporation continues, you can't stop that in an open vessel, and that raises the boiling temperature of the mixture. This is unwanted during the maillard reaction process, it needs to remain steady for a long time. On my first try it got too hot suddenly and it turned very dark quickly, the resulting syrup was acrid and not usable. On the 3rd try I knew what to watch out for and add some cold water repeatedly to reduce the boiling point of the thick sugar mixture quickly. It's easy to make it too dark way too soon.

He definitely should gain experience with sugar syrups by doing a few small batches of say 1-5 pounds progressively, so he can get a feel for what happens and what to look out and watch for. Thick bottomed pots help to diffuse heat and an accurate thermometer is paramount.

Temperature is key, so having some cold water ready to add to the bubbly sugar mixture is essential. While adding heat, evaporation continues, you can't stop that in an open vessel, and that raises the boiling temperature of the mixture. This is unwanted during the maillard reaction process, it needs to remain steady for a long time. On my first try it got too hot suddenly and it turned very dark quickly, the resulting syrup was acrid and not usable. On the 3rd try I knew what to watch out for and add some cold water repeatedly to reduce the boiling point of the thick sugar mixture quickly. It's easy to make it too dark way too soon.

Interesting. The part in red is kind've the opposite of my experience with candi syrup and brewing: for the most part my early attempts were pretty successful because I followed the processes diligently. Then I started to go fast and loose and a couple later syrups and more of my recent beers than I care to admit came out poorly, so now I'm returning to the quality control side of things to try and get back on track. I'll pass on the suggestion about starting smaller so he doesn't waste the time, sugar, and precious DAP I carried back from the States on a poorly-made 20kg batch.

Interesting. The part in red is kind've the opposite of my experience with candi syrup and brewing: for the most part my early attempts were pretty successful because I followed the processes diligently. Then I started to go fast and loose and a couple later syrups and more of my recent beers than I care to admit came out poorly, so now I'm returning to the quality control side of things to try and get back on track. I'll pass on the suggestion about starting smaller so he doesn't waste the time, sugar, and precious DAP I carried back from the States on a poorly-made 20kg batch.

I followed the process diligently too, but didn't realize that the temps keep rising as the mixture starts to contain less and less water (through evaporation) and relatively more sugar, thus raising the boiling point. The only way to keep the temp at the correct level, say 260F, is by adding small amounts of cold water, a teaspoon in a pound batch, every few minutes or when needed, even with the burner turned way down.

Strange you cannot buy DAP where you live. Di-Ammonium Phosphate is a very common chemical and ingredient.

TastyAdventure

Well-Known Member

- Joined

- Sep 15, 2013

- Messages

- 731

- Reaction score

- 51

I read this whole thread and made a lb of dark sugar for my "BDSA." I used s small amount of citric acid per another source, bc I had it in hand and apparently it works.

I simmered the sugar for 1 hr 15 min, temp was between 250-270. It did not turn out quite as dark as I hoped, and after added to the beer didn't add much color at all. There's also not a lot of deep "dark fruit" flavors in the finished product.

Should I go out and get some DAP next time? Is "Yeast Nutrient" the same thing? (I have some of that)

Also, some sources say you should up temp to 300 for darker colors, others are adamant to not get too high...

I will be trying this again for a Dubbel

I simmered the sugar for 1 hr 15 min, temp was between 250-270. It did not turn out quite as dark as I hoped, and after added to the beer didn't add much color at all. There's also not a lot of deep "dark fruit" flavors in the finished product.

Should I go out and get some DAP next time? Is "Yeast Nutrient" the same thing? (I have some of that)

Also, some sources say you should up temp to 300 for darker colors, others are adamant to not get too high...

I will be trying this again for a Dubbel

Beerswimmer

Well-Known Member

I have been making my own candi sugar/syrup for a while now. I find that I need to add date sugar to mine to get it as dark as D-180 and to have a similar flavor. I buy a pound of dates, split in half and de-seed, bake at 400 until dark and crispy, remove from heat and grind into powder. I add the date sugar to the boiling sugar with some water when the sugar gets to a dark red color and cook for another 15-20 mins or so.

I followed the process diligently too, but didn't realize that the temps kept rising as the mixture starts to contain less and less water (through evaporation) and relatively more sugar, thus raising the boiling point. The only way to keep the temp at the correct level, say 260F, is by adding small amounts of cold water, a teaspoon in a pound batch, every few minutes or when needed, even with the burner turned way down.

Strange you cannot buy DAP where you live. Di-Ammonium Phosphate is a very common chemical and ingredient.

I'm not very good at chemical name translation for the search, and none of my Chinese homebrew buddies have been able to help either. The batches I've made were all done with way overpriced yeast energizer, which I believe is DAP and dead yeast cells as a nutrient.

Interesting, that about adding water to slow down the boil. Once it starts to rise above the soft ball stage, the temperature rises really fast so the darkening does occur quickly, but I thought that was just how it was supposed to be. I'll have to try adding bits of water to slow it down next time I make a batch.

I read this whole thread and made a lb of dark sugar for my "BDSA." I used s small amount of citric acid per another source, bc I had it in hand and apparently it works.

I simmered the sugar for 1 hr 15 min, temp was between 250-270. It did not turn out quite as dark as I hoped, and after added to the beer didn't add much color at all. There's also not a lot of deep "dark fruit" flavors in the finished product.

Should I go out and get some DAP next time? Is "Yeast Nutrient" the same thing? (I have some of that)

Also, some sources say you should up temp to 300 for darker colors, others are adamant to not get too high...

I will be trying this again for a Dubbel

I think citric acid is good for caramelization and DAP is good for maillard reactions, but I'm probably wrong. I've also found that this stuff doesn't add much color - a pound of the darkest I can make (without burnt sugar flavors) barely bumps up the color of a five pound batch of beer, maybe 1-2 SRM difference.

Yeast Nutrient is generally dead yeast, it doesn't contain the chemicals needed for the reaction we're going for. Yeast energizer is a mixture of DAP and yeast nutrient, but pure DAP (I think I paid $4 for a 1 lb bag that should be adequate for around 100 lb of the darkest candi syrup in this thread) is best.

orangehero

Well-Known Member

Diammonium phosphate is pretty much the definition of yeast nutrient.

Citric acid enhances inversion, or the breakdown of sucrose into fructose and glucose, which then go on to react with nitrogen compounds (the ammonium in DAP) to form maillard products. The phosphate forms phosphoric acid and acts in a similar role when you use DAP.

High pH helps to drive maillard reactions, so the best course would be to first invert the sucrose, neutralize the acid (although you can invert just through elevated temp), and then perform the maillard forming step at a raised pH.

Also, when you change the source of nitrogen (DAP) or have a more complex source (DAP + yeast) you will create a different flavor profile.

http://www.midwestsupplies.com/yeast-energizer-vs-yeast-nutrient.html

Citric acid enhances inversion, or the breakdown of sucrose into fructose and glucose, which then go on to react with nitrogen compounds (the ammonium in DAP) to form maillard products. The phosphate forms phosphoric acid and acts in a similar role when you use DAP.

High pH helps to drive maillard reactions, so the best course would be to first invert the sucrose, neutralize the acid (although you can invert just through elevated temp), and then perform the maillard forming step at a raised pH.

Also, when you change the source of nitrogen (DAP) or have a more complex source (DAP + yeast) you will create a different flavor profile.

http://www.midwestsupplies.com/yeast-energizer-vs-yeast-nutrient.html

Diammonium phosphate is pretty much the definition of yeast nutrient.

Citric acid enhances inversion, or the breakdown of sucrose into fructose and glucose, which then go on to react with nitrogen compounds (the ammonium in DAP) to form maillard products. The phosphate forms phosphoric acid and acts in a similar role when you use DAP.

High pH helps to drive maillard reactions, so the best course would be to first invert the sucrose, neutralize the acid (although you can invert just through elevated temp), and then perform the maillard forming step at a raised pH.

Also, when you change the source of nitrogen (DAP) or have a more complex source (DAP + yeast) you will create a different flavor profile.

http://www.midwestsupplies.com/yeast-energizer-vs-yeast-nutrient.html

I stand corrected and elaborated upon. Listen to this guy - not my imprecise and occasionally wrong drivel.

Diammonium phosphate is pretty much the definition of yeast nutrient.

Citric acid enhances inversion, or the breakdown of sucrose into fructose and glucose, which then go on to react with nitrogen compounds (the ammonium in DAP) to form maillard products. The phosphate forms phosphoric acid and acts in a similar role when you use DAP.

High pH helps to drive maillard reactions, so the best course would be to first invert the sucrose, neutralize the acid (although you can invert just through elevated temp), and then perform the maillard forming step at a raised pH.

Also, when you change the source of nitrogen (DAP) or have a more complex source (DAP + yeast) you will create a different flavor profile.

http://www.midwestsupplies.com/yeast-energizer-vs-yeast-nutrient.html

Spot on!

Let me add, some yeast nutrients contain other products such as Urea, minerals, trace elements, vitamins, etc. In addition to DAP (not the caulk!), a pinch of Epsom Salt (Mg), a drop of EV olive oil, I always add a smidgen of chelated Zinc (crushed "vitamin" pills) to my yeast starter wort toward the end of the boil.

Here is a link RyanBrew's Blog with a different sugar experiment than SnickASaurusRex's (the OP).

Couple of questions as I am looking to make 3-4 lbs of sugar for a Quad I'll be brewing in the next couple weeks, waiting for a dubbel/Belgian Stout to finish fermenting to use the yeast cake for the Quad.

1. How many pounds does each "batch" make, the OP says about 1 quart, but how much is that by weight?

2. Has anybody tried making double or triple batches, since I need 3lbs of Dark Candi Syrup, let's say the OP makes 1lb, can I just triple the ingredients or should I make 3 batches? Either is fine and I would rather make 3 batches rather than attempt it and end up with 3 lbs of burnt sugar and then have to make separate batches.

3.When calculating the ABV does this work out like table sugar or is it less fermentable? If less fermentable is their a ballpark "extract potential" that can be used to figure out how much it will contribute to the OG? Mainly trying to ensure I get close to the estimated gravity instead of a lot lower. 3lbs of Candi Syrup should add about 2.8% ABV, or 18 gravity points so it could end up being a big difference.

Thanks!!!

1. How many pounds does each "batch" make, the OP says about 1 quart, but how much is that by weight?

2. Has anybody tried making double or triple batches, since I need 3lbs of Dark Candi Syrup, let's say the OP makes 1lb, can I just triple the ingredients or should I make 3 batches? Either is fine and I would rather make 3 batches rather than attempt it and end up with 3 lbs of burnt sugar and then have to make separate batches.

3.When calculating the ABV does this work out like table sugar or is it less fermentable? If less fermentable is their a ballpark "extract potential" that can be used to figure out how much it will contribute to the OG? Mainly trying to ensure I get close to the estimated gravity instead of a lot lower. 3lbs of Candi Syrup should add about 2.8% ABV, or 18 gravity points so it could end up being a big difference.

Thanks!!!

Couple of questions as I am looking to make 3-4 lbs of sugar for a Quad I'll be brewing in the next couple weeks, waiting for a dubbel/Belgian Stout to finish fermenting to use the yeast cake for the Quad.

1. How many pounds does each "batch" make, the OP says about 1 quart, but how much is that by weight?

2. Has anybody tried making double or triple batches, since I need 3lbs of Dark Candi Syrup, let's say the OP makes 1lb, can I just triple the ingredients or should I make 3 batches? Either is fine and I would rather make 3 batches rather than attempt it and end up with 3 lbs of burnt sugar and then have to make separate batches.

3.When calculating the ABV does this work out like table sugar or is it less fermentable? If less fermentable is their a ballpark "extract potential" that can be used to figure out how much it will contribute to the OG? Mainly trying to ensure I get close to the estimated gravity instead of a lot lower. 3lbs of Candi Syrup should add about 2.8% ABV, or 18 gravity points so it could end up being a big difference.

Thanks!!!

1) 1 pound of sugar makes one pound of syrup, for all good measure.

2) If you've never done it before, make 1 pound batches until you've got the hang of it. Look for the posts a little higher up re: 20 kilos of it.

3) The darker the less fermentable, but I doubt it's ever less than 80-90% fermentable, unless it turned to charcoal.

1) 1 pound of sugar makes one pound of syrup, for all good measure.

2) If you've never done it before, make 1 pound batches until you've got the hang of it. Look for the posts a little higher up re: 20 kilos of it.

3) The darker the less fermentable, but I doubt it's ever less than 80-90% fermentable, unless it turned to charcoal.

This.

1) A one pound batch will weigh a bit more than a pound when finished because you're adding a bit of water, but you're also likely to lose a bit of sugar on the walls of your pan. Sugarwise a one pound batch probably retains somewhere from 90-95% of the sugar you put into it. Of course, you could rinse that extra sugar out of the pan and into your syrup with some hot water; that would thin out the syrup and make it weigh more, but since you're adding it wort that's 98% water anyway the extra water weight won't hurt anything as long as you recognize in your calculations that it's a pound of syrup even if it weighs more than a pound.

2) The posts in question are in the last page or two. Recognize that there's a huge potential for boilover with this: the boiling sugar can foam up to several times its original volume during the process, so use a suitable cooking vessel and be ready to stir it down or manage the heat source a lot. I'm not sure how much a bigger batch will affect that, but I would be wary of going too big without some practice.

3) The Caramel Amber Ale recipe on the forums here uses a pound of this (amber-mahogany color range) and a pound and a half of C60 or C80 in a 5 gallon batch. I ferment my version of that beer with S-04, a medium-attenuating yeast, and often get FG's in the 1.002-1.004 range, which is crazy for S-04 much less a beer with a pound and a half of caramel malt. I've got to assume this is pretty near 100% fermentable in order to reach those FG's.

Thank you both for the input. Sounds sager to go with at least a couple small batches first. I made the caramel amber a few years ago, was my 3rd or 4th brew and the only trouble I had with the caramel was my thermometer stopped working in the middle of making it, otherwise it went well.

Well, that's odd.

I made this again (Syrup #5) and when it hit 250F the whole batch suddenly recrystallized!

I tried stirring it up, but it had the consistency of a pot of sand.

I added a cup of water and tried to return the syrup to liquid.

As soon as it gets close to 250F it recrystallizes! I've never seen anything like this... is it the ammonium carbonate?

I made this again (Syrup #5) and when it hit 250F the whole batch suddenly recrystallized!

I tried stirring it up, but it had the consistency of a pot of sand.

I added a cup of water and tried to return the syrup to liquid.

As soon as it gets close to 250F it recrystallizes! I've never seen anything like this... is it the ammonium carbonate?

Well, that's odd.

I made this again (Syrup #5) and when it hit 250F the whole batch suddenly recrystallized!

I tried stirring it up, but it had the consistency of a pot of sand.

I added a cup of water and tried to return the syrup to liquid.

As soon as it gets close to 250F it recrystallizes! I've never seen anything like this... is it the ammonium carbonate?

Ok, is it because I didn't invert the sugar first by boiling it for 30 minutes with citric acid?

Well, that's odd.

I made this again (Syrup #5) and when it hit 250F the whole batch suddenly recrystallized!

I tried stirring it up, but it had the consistency of a pot of sand.

I added a cup of water and tried to return the syrup to liquid.

As soon as it gets close to 250F it recrystallizes! I've never seen anything like this... is it the ammonium carbonate?

Where in recipe #5 does it mention Ammonium Carbonate? It's akin to sodium carbonate (washing soda) and very alkaline. It may cause an entirely different reaction mechanism. Perhaps you've invented something?

No way to obtain DAP? It's makes up part of many fertilizers, used on large scale, a very common and cheap ingredient.

Although it sounds intriguing, I've never made Sugar #5 so I can't tell you what to expect. But #4 at 290°F (deep amber) is easily my favorite of the dark ones. Mahogany (300°F) is a bit more difficult as it can turn to tar suddenly if the temp overshoots. Hence keeping cold water nearby. You can always bring the temps back up, but once you've exceeded certain temps you can't undo it.

Ok, is it because I didn't invert the sugar first by boiling it for 30 minutes with citric acid?

The OP's recipe does not mention inverting. Ryan's blog I mentioned before does, and goes into that a little. To completely invert, you must boil for a few hours, with acid, it's not a fast process. It's different from the caramels, though.

Where in recipe #5 does it mention Ammonium Carbonate? It's akin to sodium carbonate (washing soda) and very alkaline. It may cause an entirely different reaction mechanism. Perhaps you've invented something?

No way to obtain DAP? It's makes up part of many fertilizers, used on large scale, a very common and cheap ingredient.

Although it sounds intriguing, I've never made Sugar #5 so I can't tell you what to expect. But #4 at 290°F (deep amber) is easily my favorite of the dark ones. Mahogany (300°F) is a bit more difficult as it can turn to tar suddenly if the temp overshoots. Hence keeping cold water nearby. You can always bring the temps back up, but once you've exceeded certain temps you can't undo it.

The OP's recipe does not mention inverting. Ryan's blog I mentioned before does, and goes into that a little. To completely invert, you must boil for a few hours, with acid, it's not a fast process. It's different from the caramels, though.

I didn't invent it really, I did some related reading around the web and discovered that ammonium carbonate is Baker's Ammonia - used as a leavening agent in some cultures.

Ammonia is NH3 - a compound of nitrogen and hydrogen - we need nitrogen for the Maillard reaction and carbonate is a base to neutralize the citric acid so the syrup doesn't have a sour taste.

I am redoing the process tonight and it's working perfectly!

Here's my process:

2 Kg white sugar

500 ml water

2 gm citric acid

cook over medium heat until thermometer shows 220F. hold at 220F for 30 full minutes to invert the sucrose to fructose and glucose (simpler sugars).

add

40 gm ammonium carbonate "(NH4)2CO3"

cook at medium heat until thermometer shows 290F

add 1 cup water (watch for spatters)

cook again to 290F

add 1 cup water

cook this time to 240F and pour into preheated mason jars.

Seal hot.

They'll keep for ages.

I used this syrup in a Black IPA a couple of months ago to add colour without adding a burnt flavour and lighten the body.

I won gold in the IPA category in the most recent National competition!

The dead (thread) live again!

[emoji217]

I call it "threadsurrection".

Exactly! These kind of threads lean themselves well for going dormant for a while, ready to be awoken at any time.

It's the strange ones that suddenly pop up from the deep that are more curious.

I did this last night, I hit 290 twice and ended up with a very light caramel color syrup that tasted mostly like plain sugar with only hints of light toffee notes (I did use DAP). I heated it on medium, it seemed to only take about 15-20 minutes to reach 290 each time. I'm going to try again tonight, will I get better results if I leave it on low and let it take longer or do people try to leave it at 290 for a few minutes before adding the water?

I did this last night, I hit 290 twice and ended up with a very light caramel color syrup that tasted mostly like plain sugar with only hints of light toffee notes (I did use DAP). I heated it on medium, it seemed to only take about 15-20 minutes to reach 290 each time. I'm going to try again tonight, will I get better results if I leave it on low and let it take longer or do people try to leave it at 290 for a few minutes before adding the water?

Definitely slow it down. My experience is limited, but I've been in the same boat as you, where I needed to hit my temp two or three times to reach the desired color and flavor profile because I was heating it too fast.

Definitely slow it down. My experience is limited, but I've been in the same boat as you, where I needed to hit my temp two or three times to reach the desired color and flavor profile because I was heating it too fast.

Thanks, that was the problem. I made another batch, heated it on medium-low and also waited until it was almost boiling before I added the DAP, it took more than 1.5 hours total to reach the 290 and then 270, but the color and flavors are much better.

Ok, I see where I went wrong here...

I didn't have DAP and used Baker's Ammonia instead, but needed an acid to invert the sugar so it would stay in liquid form and not crystallize.

Not in the original post, but a few posts later, he explains that:

So, since the nitrogen source I used was bound to a base rather than an acid the sugar inversion couldn't happen.

With DAP you get both a nitrogen source for the Maillard reaction and an acid for the sugar inversion.

The method I used inverts with an acid first, then adds an alkaline nitrogen source which darkens it and neutralizes the acid.

Both achieve the same effect, but I need to do some experimentation to see what the flavour difference may be. If none, the DAP method is easier.

I didn't have DAP and used Baker's Ammonia instead, but needed an acid to invert the sugar so it would stay in liquid form and not crystallize.

Not in the original post, but a few posts later, he explains that:

DAP provides Nitrogen for mailard reactions (non enzymatic browning) to occur. These occur between ~270F and ~320F. Another source of nitrogen is ammonium bicarbonate. It is a leaven used by professional bakers.

As DAP breaks down around ~270F it separates into two molecules of ammonium and dehydrate-phosphoric acid. So it provides both the nitrogen for browning and the acid for inversion.

So, since the nitrogen source I used was bound to a base rather than an acid the sugar inversion couldn't happen.

With DAP you get both a nitrogen source for the Maillard reaction and an acid for the sugar inversion.

The method I used inverts with an acid first, then adds an alkaline nitrogen source which darkens it and neutralizes the acid.

Both achieve the same effect, but I need to do some experimentation to see what the flavour difference may be. If none, the DAP method is easier.

stever1000

Well-Known Member

- Joined

- Oct 15, 2014

- Messages

- 822

- Reaction score

- 49

I hope to make some this weekend, how crucial is a quality thermometer? I have one that is meant for high temps and for candy making, but it only reads in 10F increments

I hope to make some this weekend, how crucial is a quality thermometer? I have one that is meant for high temps and for candy making, but it only reads in 10F increments

Accuracy within 10F is fine. I would check the reading in boiling water (should be 212F if you're at or near sea level) and note the difference if any. Then correct at the higher temps with the same amount. Watch the sugar as it boils and use common sense. You can always check for soft ball stage by dropping a few drops of the syrup in a cup with cold water. It should form a soft ball when rolling between forefingers.

Start slow, you can always go up, but never back. Enjoy, it's a great process.

JayDubWill

Well-Known Member

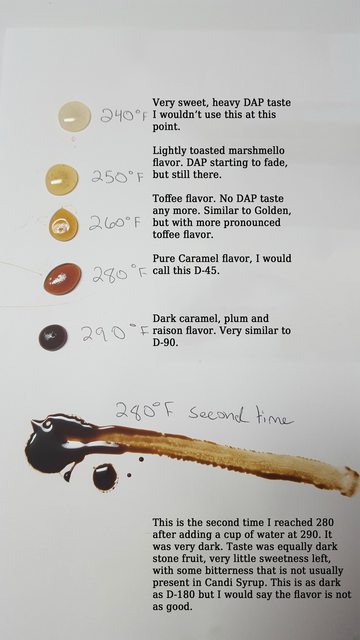

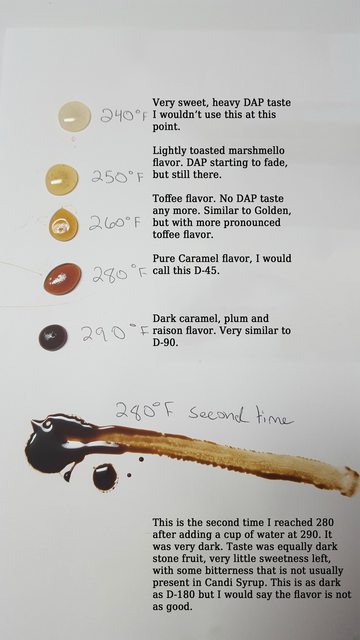

I thought I would share my results. I followed the directions for sugar #5 and also heeded the advice of go slowly. It took just under two hours total but I ran out of time to get it to 290 the second time, and honestly I felt that the flavor was heading towards roasty acrid and away from dark stone fruit so I cut it off at 280 and added the last cup of water.

Singletrack

Because it's judgement that defeats us.

Are these color palettes made prior to dilution with cooling water, or are they the final product?

Maybe it's my imagination, but my color seemed to lighten after dilution.

Maybe it's my imagination, but my color seemed to lighten after dilution.

JayDubWill

Well-Known Member

Are these color palettes made prior to dilution with cooling water, or are they the final product?

Maybe it's my imagination, but my color seemed to lighten after dilution.

With the exception of the very bottom smear these are all prior to adding the first cup of water to reduce the temp. The very bottom 280F is after adding the second cup and again bringing the water up to max temp (280, in my case). I didn't take any pictures after adding the third cup of water and bringing the temp up to 240F.

I went really slow, keeping my (electric) stove on medium low. I took an hour just to get it to 290 the first time, then another 40 minutes to get back up to 280. I increased the heat on the third "rise" to 240 since I was running out of time. Hope that clears things up.

Honestly, I don't think I would do a second rise again, I think the taste took a significant turn for the worse, but that may have been the yeast hulls in my DAP scorching. I might try it again if I can find some purer DAP, or maybe just bring it up nice and slow to 300 if I need it extra dark.

TCollins

Well-Known Member

- Joined

- Aug 7, 2015

- Messages

- 65

- Reaction score

- 6

2lb of 290 using DAP...stoked! Thanks for the recipe. By the taste it is it already appears it will be well with the effort. Though it was really simple!

TimView attachment ImageUploadedByHome Brew1447803850.688453.jpg

TimView attachment ImageUploadedByHome Brew1447803850.688453.jpg

2lb of 290 using DAP...stoked! Thanks for the recipe. By the taste it is it already appears it will be well with the effort. Though it was really simple!

TimView attachment 316730

This is 290F?

Mine seem to come out much darker at the same temperature and measurements.

Accuracy within 10F is fine. I would check the reading in boiling water (should be 212F if you're at or near sea level) and note the difference if any. Then correct at the higher temps with the same amount. Watch the sugar as it boils and use common sense. You can always check for soft ball stage by dropping a few drops of the syrup in a cup with cold water. It should form a soft ball when rolling between forefingers.

Start slow, you can always go up, but never back. Enjoy, it's a great process.

I'm using DAP now since it's easier than a 2 stage process.

I add the DAP at the beginning since the sugar needs an acid and 30 minutes of 220F to invert so it doesn't recrystallize.

I find my syrups come out quite dark, though the flavour and aroma are good.

Water boils at 205F at my altitude, should my 280 be more like 273?

I'm using DAP now since it's easier than a 2 stage process.

I add the DAP at the beginning since the sugar needs an acid and 30 minutes of 220F to invert so it doesn't recrystallize.

I find my syrups come out quite dark, though the flavour and aroma are good.

Water boils at 205F at my altitude, should my 280 be more like 273?

DAP is not an acid, and the breakdown products don't form acid either, but a base. You can smell the ammonia coming out.

There are conversion tables/calcs online to determine your altitude boiling points. It's probably closer to 10-12 degrees lower if 280F at sea level.

orangehero

Well-Known Member

It decomposes into ammonia and phosphoric acid, so to a limited extent this does accelerate inversion compared to heat alone.

TCollins

Well-Known Member

- Joined

- Aug 7, 2015

- Messages

- 65

- Reaction score

- 6

This is 290F?

Mine seem to come out much darker at the same temperature and measurements.

Yup! Maybe I screwed up? Tastes good [emoji3]

Yup! Maybe I screwed up? Tastes good [emoji3]

I dunno... maybe I screwed up. Mine tastes good too!

DAP is not an acid, and the breakdown products don't form acid either, but a base. You can smell the ammonia coming out.

There are conversion tables/calcs online to determine your altitude boiling points. It's probably closer to 10-12 degrees lower if 280F at sea level.

Ammonia and phosphoric acid. That's the acid part.

Without acid and heat there is no inversion and the sugar will recrystallize before it hits candy temperature. Perhaps it's the type of white sugar we get around here, but I need to make sure I invert the sugar before I try to take it up over 240F.

tennesseean_87

Well-Known Member

I've started to branch out from beer and cider to do a few wine kits and a mead, and I had a crazy idea. Since it's almost completely fermentable, how would this stuff work for making a wine-strength beverage like mead? Would the flavors be too strong without the sweetness? Has anyone tried it?

Similar threads

- Replies

- 0

- Views

- 1K

- Replies

- 6

- Views

- 997