I just read this entire thread and still am a little bit confused being a total electricity noob... could someone help me out here?

I'm planning on buying the ebay controller and using a cut up heavy duty extension cord for all the wiring. I want to use it only for one stage (cooling) but also want to power a fan whenever the cooling turns on.

My understanding is that I can just NOT break any tabs off, then I can just plug in both the fridge and a computer fan (wired up to a cell phone charger) and both will fire at the same time.

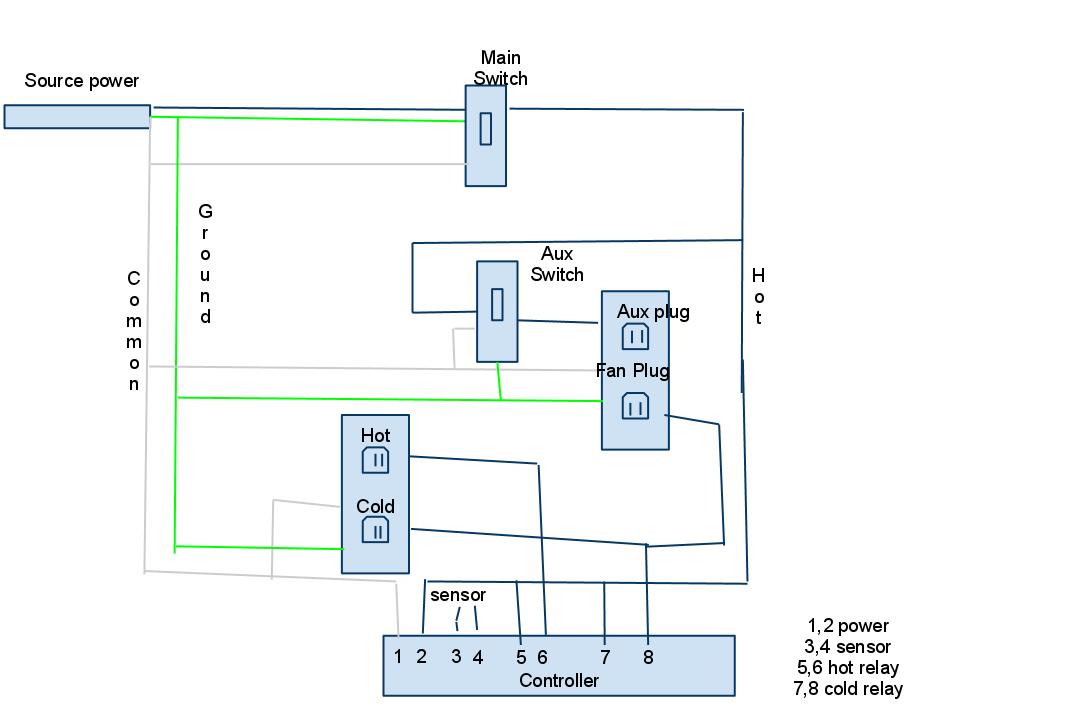

That brings me to my next question... I modified the diagram from the OP to what I think would be correct for my purpose... make sense?

It's electricity so I want to be as sure as possible that I'm doing it right before I start playing with wires.

Something else you could do is build the controller like everyone else has been talking about and make a hot/cold just in case you decide you want to use a brew belt or something in the future. In the mean time get one of those 3 outlet adapters to plug into your cold outlet and plug your freezer and fan into that.