Hi, getting ready to weld up my single tier stand soon and am looking at gathering parts for my control box. I have spent hours searching and comparing, looking at the setups of others and have many questions.

My general setup will be. Electric BK, Electric HLT, Single Infusion Batch Sparge Insulated MLT.

3 Keg system, 240v supply. 1 pump (Leaning toward the LG over the 809)

The elements will be 5500W extra low density elements. They will be controlled by two Aubern PIDs. First question:

Auberins suggested either

http://www.auberins.com/index.php?main_page=product_info&cPath=1&products_id=3

or

http://www.auberins.com/index.php?main_page=product_info&cPath=1&products_id=106

I don't understand the different specs enough to make an informed decision. They both look like they do the same thing.

They suggested the RTD probe for better accuracy. Sounds good to me, plus it looks easier to install. I notice most use the K thermocouple it comes with. Is the nicer probe not worth the $20 to most people?

The current I will draw at 100% is about 23A. Is it worth the extra few dollars to get the 40A ssr and 40A heat sink or will 25A cause me no grief?

MAJOR CONFUSION INCOMING

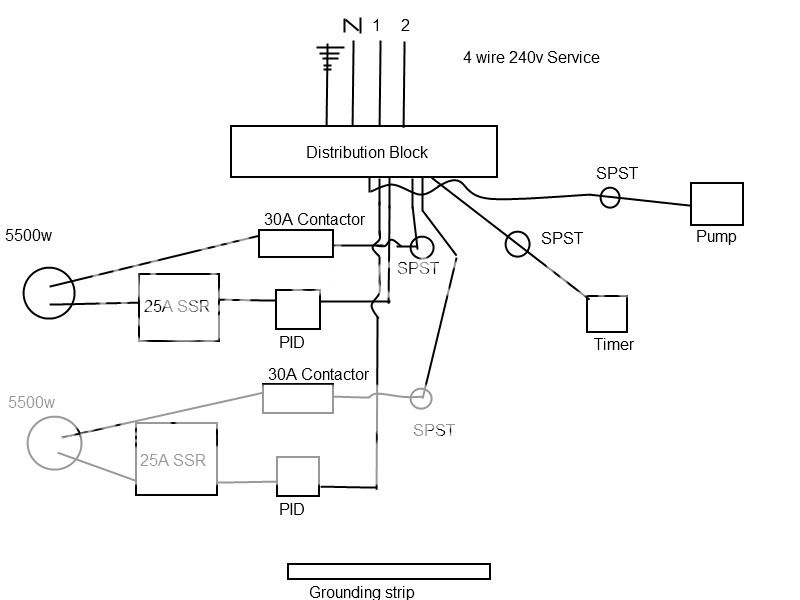

Here is where I really get screwed up. Looking at some conversation and wiring diagrams the PID and SSR only control one of my hot legs to the element. Is that accurate? Does that mean I need two SSR for each PID so I can shut the element off completely? Or is that why people get the Double Pole Single Throw toggle switch? How could you turn off the element but still have the PID on so a temperature can be read?

Luckily, a coworker's dad is an electrician that is going to help me assemble the box. I just need to figure out what to buy to get me to what I want.

What I want is 2 PID's that control the two 5500w elements. A digital hardwired timer (The $30 from Auberins). The PID/Timer need to stay on regardless of the elements being on. Toggle switches for each element and for a 120v pump. Indicator lights letting me know which element or pump is on. Maybe another 120v switch and indicator for a stirrer.

Any recommendations for switches or lights would be awesome. I want to stay away from rocker switches with the LED indicator in them.

This makes me want to take a college class on electronics as this seems to be over my head.

My general setup will be. Electric BK, Electric HLT, Single Infusion Batch Sparge Insulated MLT.

3 Keg system, 240v supply. 1 pump (Leaning toward the LG over the 809)

The elements will be 5500W extra low density elements. They will be controlled by two Aubern PIDs. First question:

Auberins suggested either

http://www.auberins.com/index.php?main_page=product_info&cPath=1&products_id=3

or

http://www.auberins.com/index.php?main_page=product_info&cPath=1&products_id=106

I don't understand the different specs enough to make an informed decision. They both look like they do the same thing.

They suggested the RTD probe for better accuracy. Sounds good to me, plus it looks easier to install. I notice most use the K thermocouple it comes with. Is the nicer probe not worth the $20 to most people?

The current I will draw at 100% is about 23A. Is it worth the extra few dollars to get the 40A ssr and 40A heat sink or will 25A cause me no grief?

MAJOR CONFUSION INCOMING

Here is where I really get screwed up. Looking at some conversation and wiring diagrams the PID and SSR only control one of my hot legs to the element. Is that accurate? Does that mean I need two SSR for each PID so I can shut the element off completely? Or is that why people get the Double Pole Single Throw toggle switch? How could you turn off the element but still have the PID on so a temperature can be read?

Luckily, a coworker's dad is an electrician that is going to help me assemble the box. I just need to figure out what to buy to get me to what I want.

What I want is 2 PID's that control the two 5500w elements. A digital hardwired timer (The $30 from Auberins). The PID/Timer need to stay on regardless of the elements being on. Toggle switches for each element and for a 120v pump. Indicator lights letting me know which element or pump is on. Maybe another 120v switch and indicator for a stirrer.

Any recommendations for switches or lights would be awesome. I want to stay away from rocker switches with the LED indicator in them.

This makes me want to take a college class on electronics as this seems to be over my head.