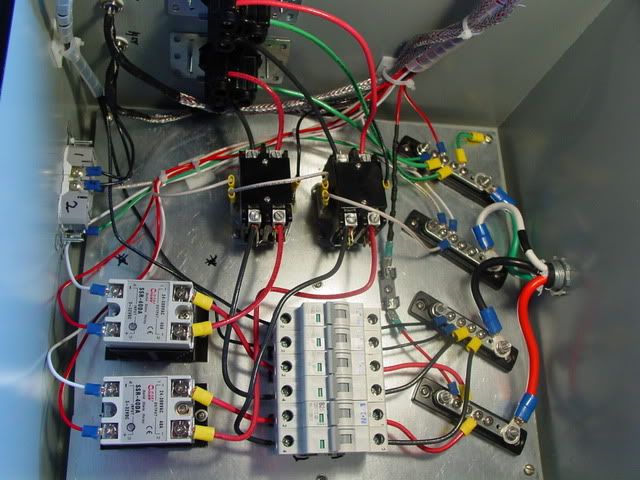

Finished wiring my enclosure finally...

Snaked the shielding from some spare coax cable for the RTD wires inside the box:

Then I wanted to put some sleeving on the RTD wires outside the box. This is mostly for some level of protection, plus it just plain looks better:

Solder on the RTD wires to the disconnect:

Slide the sleeving on:

Secure with shrink tubing:

Do the same on the other end, and this is a before and after:

Now to wire this guy into the enclosure:

[Continued on next post]

Snaked the shielding from some spare coax cable for the RTD wires inside the box:

Then I wanted to put some sleeving on the RTD wires outside the box. This is mostly for some level of protection, plus it just plain looks better:

Solder on the RTD wires to the disconnect:

Slide the sleeving on:

Secure with shrink tubing:

Do the same on the other end, and this is a before and after:

Now to wire this guy into the enclosure:

[Continued on next post]

Ive followed this thread since you started, and you've come a long way. So tell me about this vinyl lettering you have there. If you talked about it before then I missed it. Where did you get it?

Ive followed this thread since you started, and you've come a long way. So tell me about this vinyl lettering you have there. If you talked about it before then I missed it. Where did you get it?