JackSmith

Well-Known Member

As I attempt to transition from occasional brewer of OK beer to serious brewer of good beer, one of the first things I need to do is get fermentation temperature under control. To that end, I've built a chest-freezer-based fermentation chamber. The design is based on many of the keezers I've seen on this site. It's a simple 7 cubic foot chest freezer with a collar, a Love TSS2-2100, and a space heater.

Parts:

Tools:

I started off by building the collar. It's a simple box with mitered joints. I glued the corners and tacked them together with the finish nailer. While the glue was still wet, I made sure the box was square by measuring the diagonals, then installed the angle brackets. I checked for square once more, then left it overnight so the glue could set up.

The next day I planned where I wanted the Love TSS2-2100 to be mounted on the face, and the receptacle to be mounted on the back. I marked the cuts, then removed the wood by drilling the corners and connecting the dots with a coping saw. A couple coats of polyurethane, and it was time for wiring.

Wiring the Love controller was simple, thanks to all the help I found on this site, especially this diagram. Thanks Boerderij_Kabouter! I chose to wire it up such that it uses a single receptacle, split-wired so that each outlet is switched separately. The upper outlet is for heat, the lower is for cooling:

You can see in the picture above that I left the hinges in their factory position and just attached them to the collar. I wanted the collar to lift up when opening the freezer so that I wouldn't have to lift full carboys over it.

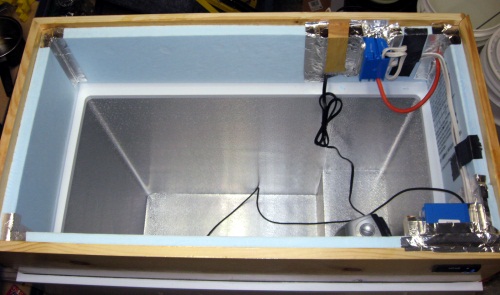

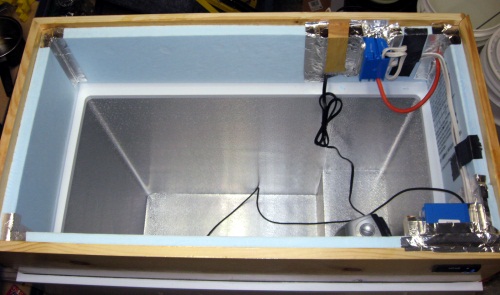

With the wiring done, I added some insulation - Blue XPS board cut to fit and stuck to the collar with spray adhesive - then sealed the corners with foil tape. Tyvek tape would be more appropriate for sealing up foam insulation, but I didn't have any on-hand but I did have aluminum duct tape. Then wome weatherstripping on the bottom of the collar and some strong double-sided tape on top for mounting the freezer lid, and it was done.

I programmed the Love controller with plenty of help from this board, particularly this post by ClaudiusB. Cheers! I tested it for a day with a carboy full of water. I taped the probe to the carboy under some bubble wrap, set SP1 to 67F, and let it go. After a few hours the carboy temp went from 77F to 67F and was very stable after 12 hours. Now, the freezer's unplugged waiting for next weekend's brew session.

I know I didn't cover any new ground with this build, but I still wanted to share. If you have any questions, I'll be happy to answer. Thanks for reading!

Parts:

- GE FCM7SUWW chest freezer, purchased new from the big box store

- Love TSS2-2100

- 14-2 Romex Wire

- Weather Stripping

- Double-sided tape

- Extruded Polystyrene insulation board

- Spray Adhesivem/heaters/model_754200.html"]Lasko 754200 Ceramic Heater[/URL]

- Standard wall receptacle and box

- Foil Tape

- Right-angle Brackets

- Wood Glue

- Polyurethane

Tools:

- Miter Saw

- Coping Saw

- Random Orbital Sander

- Finish Nailer

- Utility Knife

- Screwdrivers

- Wire snip/stripper

I started off by building the collar. It's a simple box with mitered joints. I glued the corners and tacked them together with the finish nailer. While the glue was still wet, I made sure the box was square by measuring the diagonals, then installed the angle brackets. I checked for square once more, then left it overnight so the glue could set up.

The next day I planned where I wanted the Love TSS2-2100 to be mounted on the face, and the receptacle to be mounted on the back. I marked the cuts, then removed the wood by drilling the corners and connecting the dots with a coping saw. A couple coats of polyurethane, and it was time for wiring.

Wiring the Love controller was simple, thanks to all the help I found on this site, especially this diagram. Thanks Boerderij_Kabouter! I chose to wire it up such that it uses a single receptacle, split-wired so that each outlet is switched separately. The upper outlet is for heat, the lower is for cooling:

You can see in the picture above that I left the hinges in their factory position and just attached them to the collar. I wanted the collar to lift up when opening the freezer so that I wouldn't have to lift full carboys over it.

With the wiring done, I added some insulation - Blue XPS board cut to fit and stuck to the collar with spray adhesive - then sealed the corners with foil tape. Tyvek tape would be more appropriate for sealing up foam insulation, but I didn't have any on-hand but I did have aluminum duct tape. Then wome weatherstripping on the bottom of the collar and some strong double-sided tape on top for mounting the freezer lid, and it was done.

I programmed the Love controller with plenty of help from this board, particularly this post by ClaudiusB. Cheers! I tested it for a day with a carboy full of water. I taped the probe to the carboy under some bubble wrap, set SP1 to 67F, and let it go. After a few hours the carboy temp went from 77F to 67F and was very stable after 12 hours. Now, the freezer's unplugged waiting for next weekend's brew session.

I know I didn't cover any new ground with this build, but I still wanted to share. If you have any questions, I'll be happy to answer. Thanks for reading!

.

.