SookeBrewing

Well-Known Member

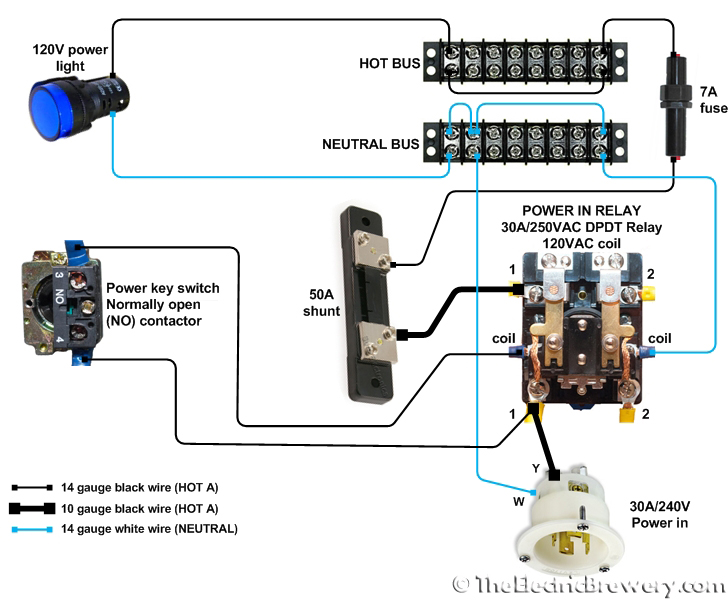

Hi all, as you may know I am working on a Kal build, and I bought some relays that another HBT user went with that were much cheaper (and enclosed which I liked).

I'm just curious about how to wire these things, since they look different than the Kal ones.

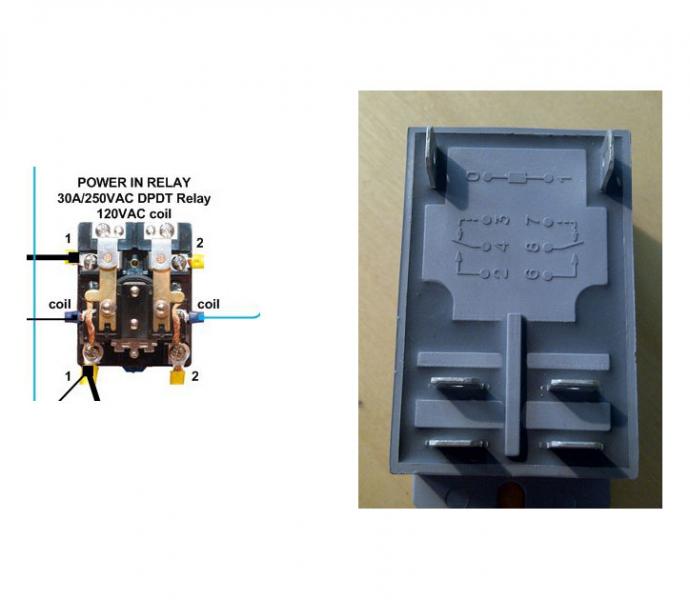

Is the picture below pretty much the way it's done? It looks similar, as far as the orientation of the terminals on my relays.

ie, is the wiring diagram on the left, how I would connect mine on the right?

Thanks!

I'm just curious about how to wire these things, since they look different than the Kal ones.

Is the picture below pretty much the way it's done? It looks similar, as far as the orientation of the terminals on my relays.

ie, is the wiring diagram on the left, how I would connect mine on the right?

Thanks!