Nice call on the red light. That would be really submarine like. That was the only bulb I had on hand so I do need a better bulb. That's just a plain old 60W bulb.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DIY Walk In Cooler Build

- Thread starter Irrenarzt

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

I went ahead and paid for the month of photobucket and I am migrating pics over to imgur. I should be able to get all the pics moved in a months time. Otherwise, it's a work week so I won't be doing much to the cooler. I do have a long weekend coming up for the holiday so I expect to be on it all weekend, except for Saturday night as Paulie is having a cheap beer party at his house, whatever that means.

Also, I got a call from the HOA guy. He wanted to come over and take pics of the shed before my meeting with the architectural board on July 9th. I was hoping to hammer out the cooler before that meeting so that they couldn't do much in terms of halting construction. Let's hope I can blow him off all week as I have a short week followed by a 4 day weekend to work on this.

Also, I got a call from the HOA guy. He wanted to come over and take pics of the shed before my meeting with the architectural board on July 9th. I was hoping to hammer out the cooler before that meeting so that they couldn't do much in terms of halting construction. Let's hope I can blow him off all week as I have a short week followed by a 4 day weekend to work on this.

So I had a slow day at work and managed to migrate all the pics to Imgur. It took awhile but I had it down there towards the end. Screw Photobucket!

so i had a slow day at work and managed to migrate all the pics to imgur. It took awhile but i had it down there towards the end. Screw photobucket!

freedom!!!

And here I am happy if I get time to attach my new drill to my Monster Mill.... You are doing a phenomenal job! I can already see you moving into the cold room during the hot(ter) months!

I am pushing to get this done ASAP because the HOA guy wants to come to take pics of the SHED. I don't think he is aware of the cooler yet. He might just schit out his left nut if he comes over and sees both.

I you going to holographically project wood panels onto the insulation?  Good luck!

Good luck!

freedom!!!

Indeed. All for the low cost of 2.99.

I also deleted a bunch of older pics to reduce the bandwidth so they can't kill it again for threads other than this one. Screw those bastiges!

I inadvertently deleted a few ones I didn't want to delete of my old 80/20 brew frame. My apologies to those of you who were interested in that. My advice is to skip the 80/20 and go stainless. You'll never see your cross members anneal and start to bend under load.

Did a little today after work:

150 W bulb:

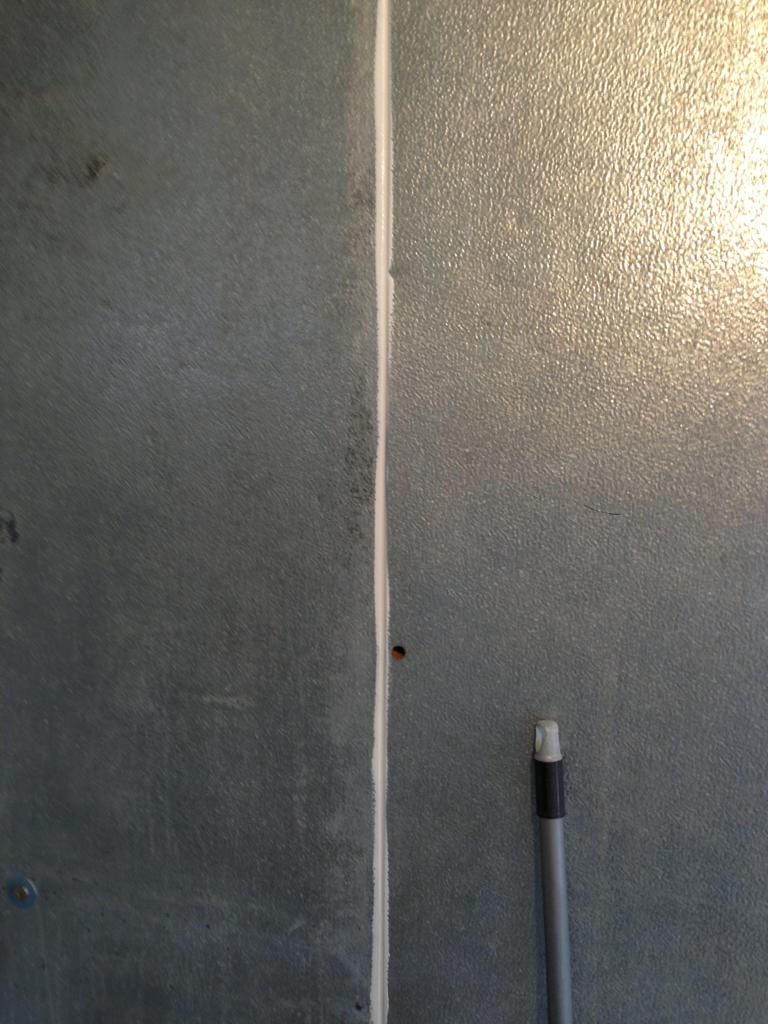

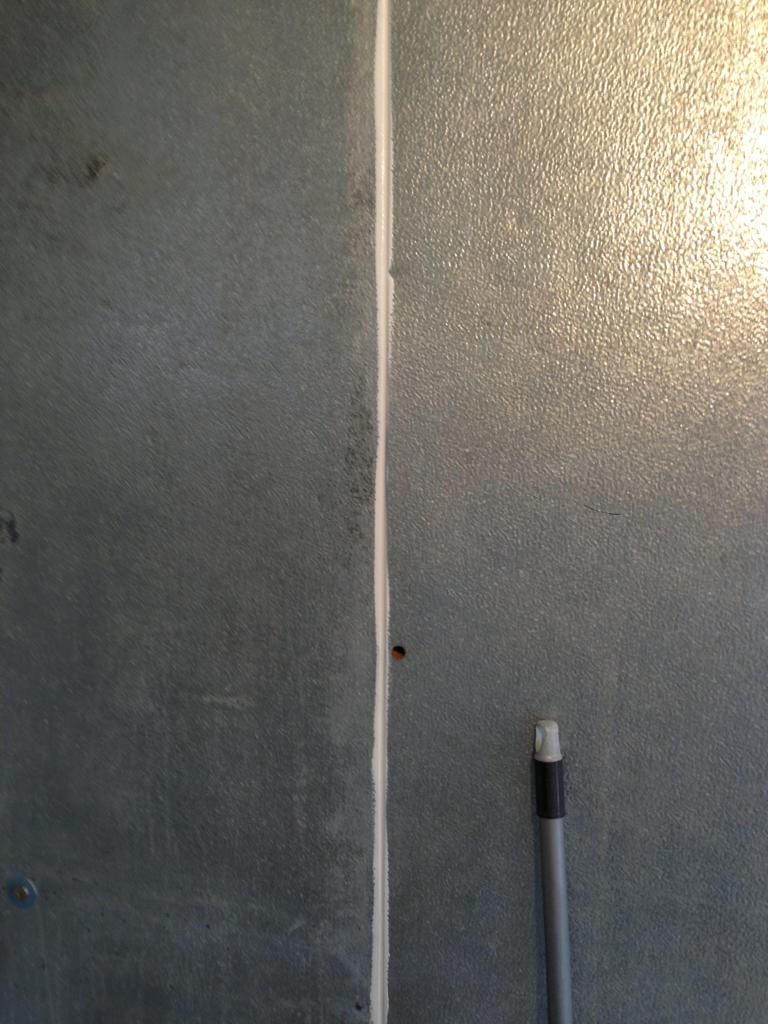

Started caulking the gaps:

150 W bulb:

Started caulking the gaps:

Again I left a couple hours early to try and get a few things done. G. Greg is at the taphouse getting drunk so he won't be of any use tonight. That's OK though as it's a mellow night.

Started flashing the seams:

More about an hour later:

What you cannot see is that besides caulking the seam between each panel, I am running a bead of PL Premium Advanced along each side of the seam to bond the flashing to the cooler panel. Then I am screwing them in with sheet metal screws, which bite pretty well for future reference.

Started flashing the seams:

More about an hour later:

What you cannot see is that besides caulking the seam between each panel, I am running a bead of PL Premium Advanced along each side of the seam to bond the flashing to the cooler panel. Then I am screwing them in with sheet metal screws, which bite pretty well for future reference.

Happy Independence Day everyone. Today I have a beer tasting to attend at 5 but in the meantime, I'm returning a bunch of extra stuff to the home depot and picking up some new supplies. I'll probably get some work done this afternoon but I doubt I can get much done today. Greg is tied up with his own projects so his involvement is winding down it appears. We should have a big push this weekend though, even without him.

I wanted to ask what people think I should use to bond the wrinkled plastic sheeting to the foam on the back of the door? I like Deep Six's idea of foam on the back of the door but I'm not sure what to use to mount the plastic? I'm thinking PL Premium as this stuff bonds just about everything it seems.

Lizard chillaxin' in the hot air gap where the heat escapes from the inner thermal barrier layer. Didn't expect the reptiles to be hanging out there but it is warm there. On the west AC side wall, you can blow out a match with the thermal exhaust in the peak heat of the day. That stuff is impressive but we still need to cut out a bit more of the stucco scratch and brown to help the intake of air at the bottom. Devil is in the details...

Started swapping out the hex lags for the torx ones (you might recall I had to get hex ones to sub as the torx ones were out of stock but I got a new box of torx ones at HD this morning). Also got the strip in just to the right of and up to the AC opening:

It wrinkled a bit which makes it look even more Iron Man prototype but it'll get painted over soon enough.

I got a bunch of 90 degree flashing today so I'm starting to wrap all the exposed foam edges for protection around the service panel/AC opening:

I had to make a 2.5" in x 3/4" deep cutout for the AC box:

I wanted to ask what people think I should use to bond the wrinkled plastic sheeting to the foam on the back of the door? I like Deep Six's idea of foam on the back of the door but I'm not sure what to use to mount the plastic? I'm thinking PL Premium as this stuff bonds just about everything it seems.

Lizard chillaxin' in the hot air gap where the heat escapes from the inner thermal barrier layer. Didn't expect the reptiles to be hanging out there but it is warm there. On the west AC side wall, you can blow out a match with the thermal exhaust in the peak heat of the day. That stuff is impressive but we still need to cut out a bit more of the stucco scratch and brown to help the intake of air at the bottom. Devil is in the details...

Started swapping out the hex lags for the torx ones (you might recall I had to get hex ones to sub as the torx ones were out of stock but I got a new box of torx ones at HD this morning). Also got the strip in just to the right of and up to the AC opening:

It wrinkled a bit which makes it look even more Iron Man prototype but it'll get painted over soon enough.

I got a bunch of 90 degree flashing today so I'm starting to wrap all the exposed foam edges for protection around the service panel/AC opening:

I had to make a 2.5" in x 3/4" deep cutout for the AC box:

Crowemagnonman

Member

- Joined

- Jul 4, 2013

- Messages

- 9

- Reaction score

- 1

Amazing build! Wish I could be more help with your questions, but I no construct good

Happy Independence Day everyone. Today I have a beer tasting to attend at 5 but in the meantime, I'm returning a bunch of extra stuff to the home depot and picking up some new supplies. I'll probably get some work done this afternoon but I doubt I can get much done today. Greg is tied up with his own projects so his involvement is winding down it appears. We should have a big push this weekend though, even without him.

I wanted to ask what people think I should use to bond the wrinkled plastic sheeting to the foam on the back of the door? I like Deep Six's idea of foam on the back of the door but I'm not sure what to use to mount the plastic? I'm thinking PL Premium as this stuff bonds just about everything it seems.

Lizard chillaxin' in the hot air gap where the heat escapes from the inner thermal barrier layer. Didn't expect the reptiles to be hanging out there but it is warm there. On the west AC side wall, you can blow out a match with the thermal exhaust in the peak heat of the day. That stuff is impressive but we still need to cut out a bit more of the stucco scratch and brown to help the intake of air at the bottom. Devil is in the details...

I think that your walk-in cooler compares to professionally-made ones like craft beer does to "mainstream" beers. You love what you're doing and your attention to detail is phenomenal! It will be better than anything anyone else would have built for you!

Thanks Funny. I appreciate the kind words. I'm taking a lunch break now but I'll be back at it. Got off to a slow start this morning as I needed to sleep in a bit today.

Got the service port all corner flashed:

Added bitumen based waterproofing to the sill where the AC will sit:

Got the side studs as well:

The AC port prepped and flashed. Should be able to withstand some water now. I had to cover the thermal vents for that section but I had no choice as it would have had exposed OSB edges which won't withstand much water at all:

AC case all cleaned and ready to mount:

If you build a cooler, don't leave your AC unit outside for 2 months while you build as it'll get filthy with sawdust and other dirt and it'll be a ***** to clean. Don't open the box until you have to.

Started priming the trim:

Drilling out 3" holes for venting the airspace above the flat and sloped roofs:

Painted the OSB that will go under the eaves:

Back to mounting the AC case:

Big props to my man Reagor who came down to help install the AC unit. You definitely need two people to get that fracker in place.

AC unit in place:

It's working fine luckily. Even after spending half an hour washing it out as it was full of dirt and pink insulation dust.

Foamed the gaps:

I will wait for the foam to cure and try to dress it up a bit by cutting it flat and capping it somehow.

I had dinner and a couple beers and went back to cutting excess foam. I will also need a different cover for the electrical box as I had to cut the hell out of the current one just to get the plug to fit in the enclosure. I had to cut off the latching part so now the cover won't snap shut, but the AC plug now fits. I think one without a cover will have to do. The AC plug has a GFCI built in so it should protect me if it gets wet.

The devil is in the details. Back to it tomorrow. Gotta like these long weekends.

Got the service port all corner flashed:

Added bitumen based waterproofing to the sill where the AC will sit:

Got the side studs as well:

The AC port prepped and flashed. Should be able to withstand some water now. I had to cover the thermal vents for that section but I had no choice as it would have had exposed OSB edges which won't withstand much water at all:

AC case all cleaned and ready to mount:

If you build a cooler, don't leave your AC unit outside for 2 months while you build as it'll get filthy with sawdust and other dirt and it'll be a ***** to clean. Don't open the box until you have to.

Started priming the trim:

Drilling out 3" holes for venting the airspace above the flat and sloped roofs:

Painted the OSB that will go under the eaves:

Back to mounting the AC case:

Big props to my man Reagor who came down to help install the AC unit. You definitely need two people to get that fracker in place.

AC unit in place:

It's working fine luckily. Even after spending half an hour washing it out as it was full of dirt and pink insulation dust.

Foamed the gaps:

I will wait for the foam to cure and try to dress it up a bit by cutting it flat and capping it somehow.

I had dinner and a couple beers and went back to cutting excess foam. I will also need a different cover for the electrical box as I had to cut the hell out of the current one just to get the plug to fit in the enclosure. I had to cut off the latching part so now the cover won't snap shut, but the AC plug now fits. I think one without a cover will have to do. The AC plug has a GFCI built in so it should protect me if it gets wet.

The devil is in the details. Back to it tomorrow. Gotta like these long weekends.

Slow start today as I slept in a bit. I went to the dump early, grabbed a 20 oz Red Bull and a burrito and got to work.

Got a couple more pieces of flashing in:

Ran out of these kind of screws so I need to go back to the Home Despot. Luckily Paulie is having a cheap beer party tonight so I can hit there on the way to his house.

Got the trim framing on the door up:

I needed something to fill that gap that I can nail into for the case moulding that will go up later.

Got the soffits up as well:

Got a couple more pieces of flashing in:

Ran out of these kind of screws so I need to go back to the Home Despot. Luckily Paulie is having a cheap beer party tonight so I can hit there on the way to his house.

Got the trim framing on the door up:

I needed something to fill that gap that I can nail into for the case moulding that will go up later.

Got the soffits up as well:

It's really hot today so I'm taking a break for now. I need some stuff at the Home Depot so the only thing I can do right now is stucco but it's too hot for that.

I'm meeting with the HOA's architectural committee on the 9th, which is coming up soon. I'll see what they say then.

Which gap are you referring to?

Got some cloud cover so got back to it.

SECOND color coat on shed to fix Marshall's Helen Keller paint mess:

Color coat going up on the walk in:

You can clearly see the color lightens up quite a bit as it dries.

I'm meeting with the HOA's architectural committee on the 9th, which is coming up soon. I'll see what they say then.

Which gap are you referring to?

Got some cloud cover so got back to it.

SECOND color coat on shed to fix Marshall's Helen Keller paint mess:

Color coat going up on the walk in:

You can clearly see the color lightens up quite a bit as it dries.

- Joined

- May 6, 2013

- Messages

- 14,033

- Reaction score

- 3,377

damn those look great, i dont think the HOA will be able to complain about anything once they see them

Well I know for sure the roofing material (the galvanized corrugated) is not an "allowed" building material so either I will have to get a variance or paint it. I'll learn more on the 9th.

Cooler is officially stucco'd:

Off to Paulie's to drink some schwag brew.

Off to Paulie's to drink some schwag brew.

Looks awesome. And the gap I think is on the above pic. You had mentioned "I needed something to fill that gap that I can nail into for the case moulding that will go up later." And wasnt sure if the the area above the door and down the side. Your craftsmanship has been amazing so far so you can tell whatever you choose it will be great.

That's damned sexy, if the HOA guy gives you a hard time you could keep him in there for a while till ya get a chance to bury him out in the dessert.

LOL

LOL

That's damned sexy, if the HOA guy gives you a hard time you could keep him in there for a while till ya get a chance to bury him out in the dessert.

LOL

It should almost always be considered as the last option, but sometimes you just have to dig a hole.

There is also a strong solution of sodium hydroxide. Never discount the chemical option as it's usually less labor intensive.

It's wicked hot out today so I'm just taking it kind of easy. I went to make a dump run earlier, then stopped at the store to get stuff to make a big crockpot of green chile bacon baked beans.

I also wetted down the color coats but no pics of that as that's kind of boring. Next I cut some cured foam from last night:

I sprayed in some additional foam after that:

I had the AC blowing on me while I was doing that. It definitely works.

I think I'll work on the door after lunch while the foam cures.

Reagor came over after lunch. He actually brought a breakfast burrito for me which was a bit poorly timed but tasty nonetheless.

We took an old walk in panel, ripped off all the steel cladding and cut it to fit the back of the door. We then glued it to the door with PL Premium and weighted it down with a box of tiles and the shelving units for the walk in:

After that we took a Session break:

Sorry for the blurry pic, I was being too fast when I took that pic.

Then it started raining like a motherf'er:

Bad time to take the door off the cooler unfortunately:

Again sorry for the blurry shot.

I also wetted down the color coats but no pics of that as that's kind of boring. Next I cut some cured foam from last night:

I sprayed in some additional foam after that:

I had the AC blowing on me while I was doing that. It definitely works.

I think I'll work on the door after lunch while the foam cures.

Reagor came over after lunch. He actually brought a breakfast burrito for me which was a bit poorly timed but tasty nonetheless.

We took an old walk in panel, ripped off all the steel cladding and cut it to fit the back of the door. We then glued it to the door with PL Premium and weighted it down with a box of tiles and the shelving units for the walk in:

After that we took a Session break:

Sorry for the blurry pic, I was being too fast when I took that pic.

Then it started raining like a motherf'er:

Bad time to take the door off the cooler unfortunately:

Again sorry for the blurry shot.

- Joined

- Mar 18, 2012

- Messages

- 2,418

- Reaction score

- 3,058

Will your cooling unit be able to cool the room down. A/C is less efficient when it's hot outside.

Have you not read all 27 pages of this thread? Nanook of the North could live quite happily in this epic build.

Irrenarzt, you have my admiration for your attention to detail and doing it right the first time. Well, except for that little painting hiccup.

I take responsibility for not paying closer attention to Marshall. He did say he knew how to paint and I tend to give people the benefit of the doubt. That he fracked up so bad is really hard to believe and it was a setback, but the damage has been repaired. I'm moving on and I hope that kid figures out his way in life. He dropped out of high school which I find hard to believe as they basically just give you a diploma for showing up these days. Poor kid better figure something out quick.

Thanks for the good words. And yes, the AC is overspec'd for the volume I am cooling. See here:

http://www.storeitcold.com/sizebrand.html

My cooler is 12' x 6' nominally but it's actually a bit smaller inside since my walls are so thick. My inner dimensions ended up being 10' 9" long x 5' 5" wide x 7' high. This 24kBTU AC unit will easily cool this space I think. Also I have a feeling the HOA is going to make me put up some screening and paint the galvanized roofing. I will likely have to put up some kind of fencing but I think I can get away with solar screening on the west cooler wall which will help keep the AC unit cooler, which in turn will make it work less hard. I had the AC running today and it was down to 59 in about 5 minutes with no door seals, no door insulation, and a 3" hole in the wall leading into the garage where it was 85 F.

Thanks for the good words. And yes, the AC is overspec'd for the volume I am cooling. See here:

http://www.storeitcold.com/sizebrand.html

My cooler is 12' x 6' nominally but it's actually a bit smaller inside since my walls are so thick. My inner dimensions ended up being 10' 9" long x 5' 5" wide x 7' high. This 24kBTU AC unit will easily cool this space I think. Also I have a feeling the HOA is going to make me put up some screening and paint the galvanized roofing. I will likely have to put up some kind of fencing but I think I can get away with solar screening on the west cooler wall which will help keep the AC unit cooler, which in turn will make it work less hard. I had the AC running today and it was down to 59 in about 5 minutes with no door seals, no door insulation, and a 3" hole in the wall leading into the garage where it was 85 F.

Had to stop for the day as I was getting ambitious and tried to put up a 10' overhead corner flashing around a corner by myself and totally screwed it up. I wasn't liking it so I took it down and threw it in the back of the truck. Time to eat and have a few beers. Got a lot done this weekend so it's a good time to call it.

Should have been patient and waited for someone to help me hold it up. I was a little too anxious. I want to get this damn thing done.

Should have been patient and waited for someone to help me hold it up. I was a little too anxious. I want to get this damn thing done.

nsring

Member

Have you thought about putting solar panels on the roof to cut back AC electricity costs? HOA probably wouldn't dog that.

Have you thought about putting solar panels on the roof to cut back AC electricity costs? HOA probably wouldn't dog that.

I have considered it and it is a possibility as the tax incentives are good. You can write off the entire cost of the cooler as well as it would be considered construction related to the solar power upgrade but I would need to finance about 25K, of which about 10K would be recoverable in about 9 months. The system would definitely be beneficial in the long run. I'd prefer not to have the additional payment at this time but it is definitely something worth considering.

Definitely following this. I've read all 270 posts now and am intrigued! Beautiful work my friend! And here all I want to cool down is an inside bar! lol

Unfortunately, the taps will be in the garage, not in the cooler itself. Once we get the shelving in, I doubt there will be a whole lot of room to be hanging out in there.

Gotcha. How about a chest freezer that fits in the space you have? An AC unit, even a small one, will take up a lot of space. Perhaps a chest freezer with a temperature controller is a better option? Then you can run lines through the lid to a tower on the bar?

I have considered it and it is a possibility as the tax incentives are good. You can write off the entire cost of the cooler as well as it would be considered construction related to the solar power upgrade but I would need to finance about 25K, of which about 10K would be recoverable in about 9 months. The system would definitely be beneficial in the long run. I'd prefer not to have the additional payment at this time but it is definitely something worth considering.

If you are persuing this avenue I hear that sometimes you can arrange with the DOT the purchase of lightly used solar panels from their signs. Apparently they often have rules where after so long or if output is less than a certain amount they have to get rid of them. Worth checking out to save some money.

Worth looking at, thanks for the tip.

johnsnownw

Well-Known Member

Solar charging, eh?

4 of these = 1000 watts @ $1500

http://www.amazon.com/dp/B00635Y1AQ/?tag=skimlinks_replacement-20

This little guy = $573

http://www.amazon.com/dp/B0052UIPIC/?tag=skimlinks_replacement-20

Deep Cycle Battery Bank with relevant connectors = $1200 or so

Power Inverter = $500

Final Cost: $3,773.

I'm considering something similar in the future when we purchase an electric vehicle...would be nice to at least partially charge it from solar.

You live in a climate that is pretty much perfect for solar power...I'd be seriously looking into it if I lived there...granted you've just put quite a dent in your finances recently.

4 of these = 1000 watts @ $1500

http://www.amazon.com/dp/B00635Y1AQ/?tag=skimlinks_replacement-20

This little guy = $573

http://www.amazon.com/dp/B0052UIPIC/?tag=skimlinks_replacement-20

Deep Cycle Battery Bank with relevant connectors = $1200 or so

Power Inverter = $500

Final Cost: $3,773.

I'm considering something similar in the future when we purchase an electric vehicle...would be nice to at least partially charge it from solar.

You live in a climate that is pretty much perfect for solar power...I'd be seriously looking into it if I lived there...granted you've just put quite a dent in your finances recently.

Last edited by a moderator:

Loving this thread - been following from the slidelines and read every post. Thought I'd share a little bit about my own similar project.

I'm building a walk-in wine/beer cooler for wine barrels/bottles, and cellared beer (kegs and bottles). I'll maintain it around 55F, not ideal for beer but great for wine which is where my larger investment lies. I'm not half as handy as you, so I've had to outsource building of the main structure. I'm going to insulate it myself though, and use a wine cooling unit to maintain temp and humidity.

Thanks for some great ideas and inspiration!

I'm building a walk-in wine/beer cooler for wine barrels/bottles, and cellared beer (kegs and bottles). I'll maintain it around 55F, not ideal for beer but great for wine which is where my larger investment lies. I'm not half as handy as you, so I've had to outsource building of the main structure. I'm going to insulate it myself though, and use a wine cooling unit to maintain temp and humidity.

Thanks for some great ideas and inspiration!

Excellent. I'm glad this thread will be of value to others building a similar structure.

On a more worrisome note, I have to go meet the HOA architectural board tonight after work. The compliance officer called me this morning and left a message saying he was going to go take pictures this afternoon from the back yard for tonight's meeting. Apparently something they consider is screening and he wanted to evaluate the need for screening by taking comprehensive pictures of the layout.

I submitted drawings about 10 days ago for the shed, not the cooler. So the cat will be out of the bag as he will certainly see it and photograph it. I will have to explain the cooler.

My argument will be that I built the shed first, and that the cooler is identical to the shed with the exception of insulation and power/AC and that I wanted to discuss the shed first as it was built first. I'm not sure what they will say but it could be ugly.

If anyone has a better argument, I am open to suggestions.

On a more worrisome note, I have to go meet the HOA architectural board tonight after work. The compliance officer called me this morning and left a message saying he was going to go take pictures this afternoon from the back yard for tonight's meeting. Apparently something they consider is screening and he wanted to evaluate the need for screening by taking comprehensive pictures of the layout.

I submitted drawings about 10 days ago for the shed, not the cooler. So the cat will be out of the bag as he will certainly see it and photograph it. I will have to explain the cooler.

My argument will be that I built the shed first, and that the cooler is identical to the shed with the exception of insulation and power/AC and that I wanted to discuss the shed first as it was built first. I'm not sure what they will say but it could be ugly.

If anyone has a better argument, I am open to suggestions.

Similar threads

- Replies

- 4

- Views

- 926

- Replies

- 6

- Views

- 679