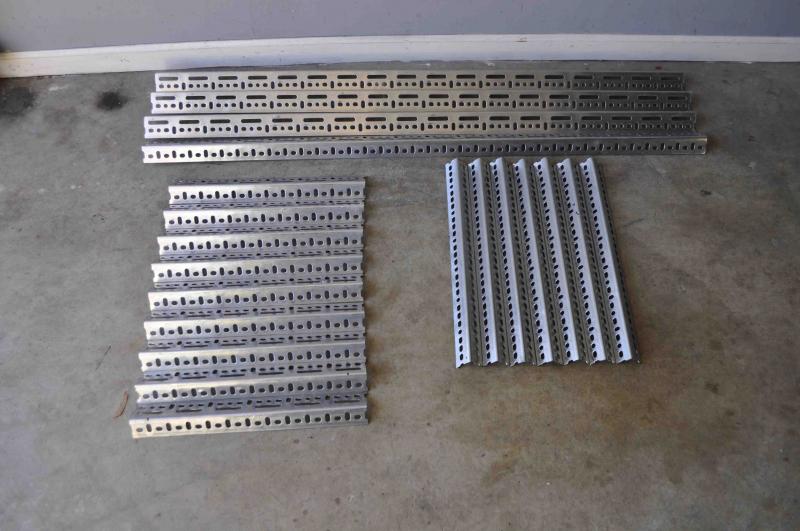

Miscue - No, I didn't purchase any more materiel to add the mounting bracket for the pumps. I used the Wallace build pictures as a guide when I built mine. I used the 2-1/4 x 1-1/2" for the frame of the stand. Basically the two long rectangles that are connected by the legs are cut from the bigger pieces of steel. Below is how I cut the 2-1/4x1-1/2" steel; if you are careful you will have one 6' length left over.

|____________ 52"____|___16.5"_____|

----------------------------------------- x 4

|__16.5__|__16.5__|__16.5__|__16.5__|

----------------------------------------- x 1

|______________72"__________________|

----------------------------------------- x 1

I cut the 1-1/2 x 1-1/2 steel like below. The fifth one is used as a support on the back side of the frame. the other four are used as the legs of the frame.

|___21____|___21____|___21____|

-------------------------------------

|___21____|___21____|

-------------------------------------

This left over angle let me cut 3 more 21" pieces from the 2-1/4x1-1/2" to use as a pump mount. you can see it on post #89 of the thread on the last two pictures. I also reinforced the pump mount with more scrap leftover from the build. I will post pictures later today, my two year old needs her breakfast.

I hope this helps. If you have any more questions just shoot me a pm.

Jabin