OEHokie

Well-Known Member

I'm having trouble deciding where to put stuff around my march pump. As far as march pump performance goes... what's more important... tube resistance or gravity?

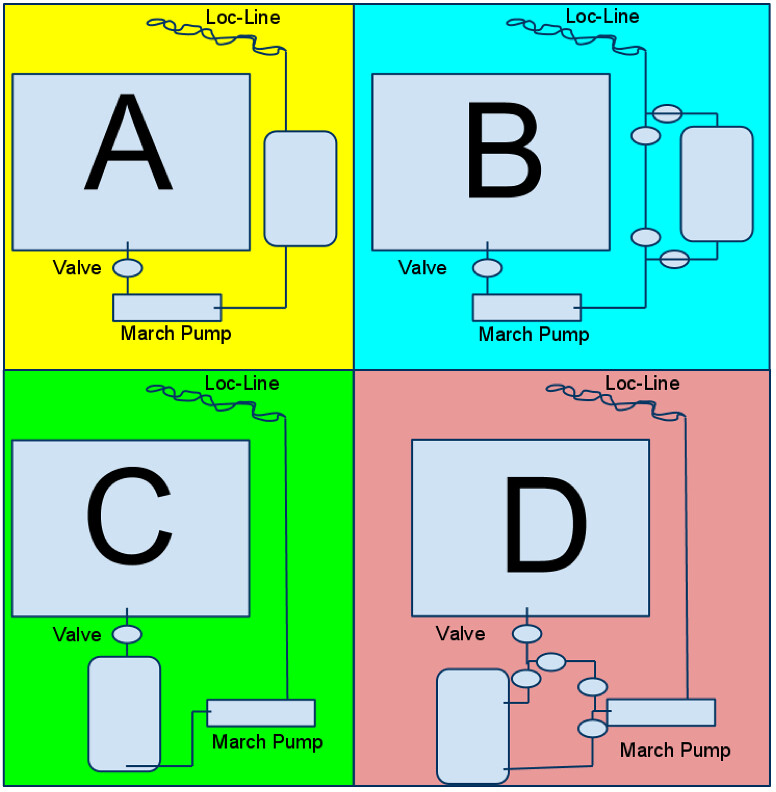

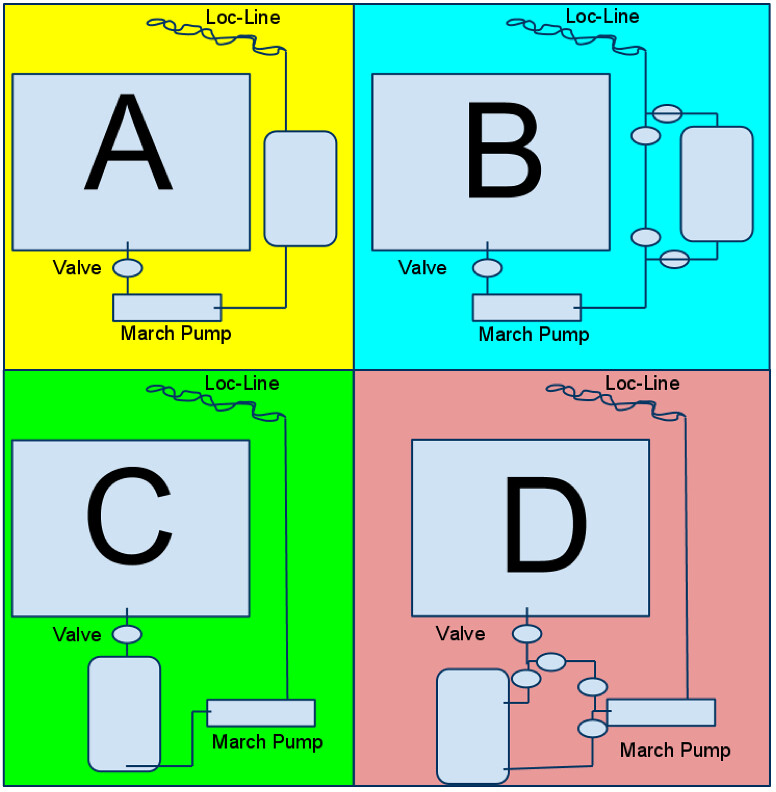

Option A: In-line after pump (Flow always goes through the chillzilla)

Option B: Valved after pump (Flow only goes through chillzilla at the end)

Option C: In-line before pump

Option D: Valved before pump

I'm leaning towards option C or D. I feel like working with the gravity to bring the wort through the chillzilla will help. In C and D the march pump would be oriented towards the bottom of the chillzilla. In A and B the chillzilla will be above the march pump.

In all cases the output of the loc-line will be towards the bottom of the kettle (but only during the cooling process).

Piping will either be stainless steel or silicone The height of the kettle is probably about 2 feet.

Edit: I'm going to go with the After the Pump/Valved Configuration. Should be easier on the pump for the times when I'm not using the chillzilla.

I'm also going to add another T at the start, after the kettle valve, for another outside input.

Thanks for the feedback!

Option A: In-line after pump (Flow always goes through the chillzilla)

Option B: Valved after pump (Flow only goes through chillzilla at the end)

Option C: In-line before pump

Option D: Valved before pump

I'm leaning towards option C or D. I feel like working with the gravity to bring the wort through the chillzilla will help. In C and D the march pump would be oriented towards the bottom of the chillzilla. In A and B the chillzilla will be above the march pump.

In all cases the output of the loc-line will be towards the bottom of the kettle (but only during the cooling process).

Piping will either be stainless steel or silicone The height of the kettle is probably about 2 feet.

Edit: I'm going to go with the After the Pump/Valved Configuration. Should be easier on the pump for the times when I'm not using the chillzilla.

I'm also going to add another T at the start, after the kettle valve, for another outside input.

Thanks for the feedback!