runningweird

Well-Known Member

So I got an old 6 tap tower from a kind gentleman in Florida and I set about trying to get my giant 26 cubic foot freezer inside the house so I could make a keezer. Needless to say the house is too small and the freezer to big, so in a flash one late night I decided to put the kegs in the basement in a fridge and run a line upstairs to the tower.

This is how it started – a cheap pine cabinet from Just Cabinets – I am not a woodworker( at least not a good one) and the tower.

The original owner had dissasembled the tower for shipping, and after an hour in a hardware store searching for a bolt/screw that I thought would work I gave up and called perlick. They said haha you are dumb, not a screw, a pop rivet. So off to the pop rivet section I went. a few stainless washers and I was all set, what was once a rickety tower was now sturdy and solid.

I ordered a 100 foot roll of that bev line offered by BirdManBrewing a while back in the vending section. That stuff is hard to get on the barbs but once on there it will not come off.

you can see that I added hose clamps - i was just trying to be cautious and as of right now with three lines running there are no leaks.

After reading about how to keep beer cool along the lines I was either going to use the glycol setup in the tower or use a fan, the space constraints got me to go with the glycol lines - instead of glycol I am using saltwater in a bucket in the freezer of my fridge downstairs and a 29 dollar pond pump from Lowes that advertised a head height of 4.1 feet.

The glycol setup was made of copper while the beer lines were stainless steel coming out of the tower. Onto the copper glycol pipes I fitted 1/2 inch vinyl tubing - around 15 feet long on both the in and out - and onto the beer lines I put the accuflex bev tubing. Getting those on was tough and required lots of cursing and two pots full of hot water. A pro tip for using this stuff - use welders gloves to handle it after taking it out of the hot water.

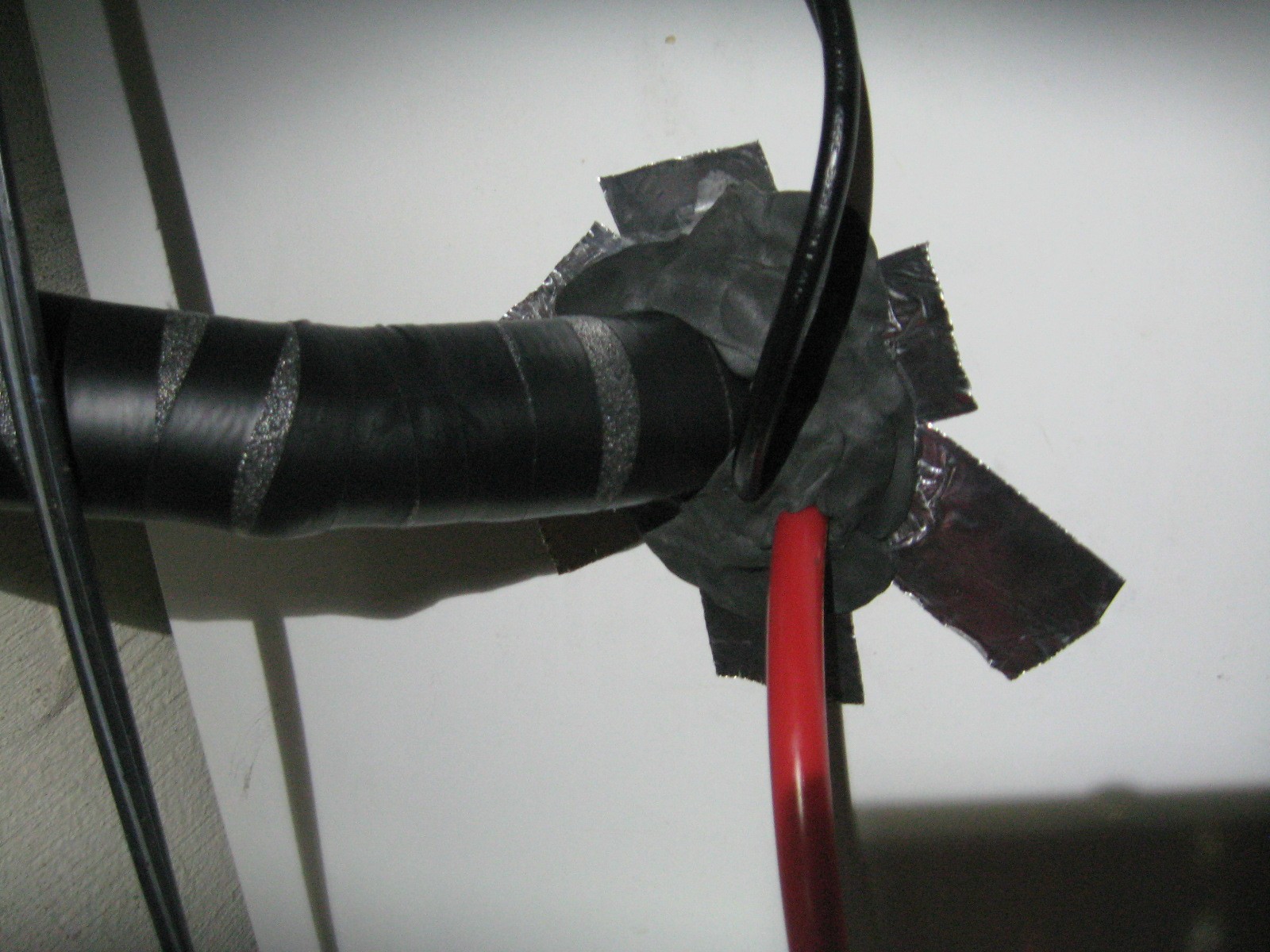

To make the trunk line - instead of buying one for 98 dollars a foot premade - I placed all the beer lines around one of the vinyl tubes(which had been arbitrarily chosen to be the "cold fluid to the tower" line in a semicircle to keep them in contact with the cold fluid and keep down foam. I secured the return line to the back of the cold line and secured them all together with zip ties every few inches. I know that professional trunk lines have a plastic interior, so I decided to make the interior easier to work with and try to stop condensation by wrapping the entire thing in saran wrap. worked pretty well and made getting the foam closed up easier than it could have been.

The foam had two self adhesive sides that stuck together to hold the tubing shut, I wanted more than that so I decided a wrapping with electrical tape would help - and it did. It made feeding the line through the hold I cut to the basement a lot simpler and rip free. I even had my son help me do it - and telling an 11 year old what to do with something like this while you yell commands and directions through the living room floor is not supposed to be as easy as it was.

EDIT: I had one of the QD posts break off of the bev seal line and tried the boiling water thing to fix it( which involved a jet boil stove, a headlamp and me burning my fingers and some arm hair. I bought a heat gun for $20 from True value which made working with the tubing so much easier. A heat gun is a must for anyone using this tubing.

This is how it started – a cheap pine cabinet from Just Cabinets – I am not a woodworker( at least not a good one) and the tower.

The original owner had dissasembled the tower for shipping, and after an hour in a hardware store searching for a bolt/screw that I thought would work I gave up and called perlick. They said haha you are dumb, not a screw, a pop rivet. So off to the pop rivet section I went. a few stainless washers and I was all set, what was once a rickety tower was now sturdy and solid.

I ordered a 100 foot roll of that bev line offered by BirdManBrewing a while back in the vending section. That stuff is hard to get on the barbs but once on there it will not come off.

you can see that I added hose clamps - i was just trying to be cautious and as of right now with three lines running there are no leaks.

After reading about how to keep beer cool along the lines I was either going to use the glycol setup in the tower or use a fan, the space constraints got me to go with the glycol lines - instead of glycol I am using saltwater in a bucket in the freezer of my fridge downstairs and a 29 dollar pond pump from Lowes that advertised a head height of 4.1 feet.

The glycol setup was made of copper while the beer lines were stainless steel coming out of the tower. Onto the copper glycol pipes I fitted 1/2 inch vinyl tubing - around 15 feet long on both the in and out - and onto the beer lines I put the accuflex bev tubing. Getting those on was tough and required lots of cursing and two pots full of hot water. A pro tip for using this stuff - use welders gloves to handle it after taking it out of the hot water.

To make the trunk line - instead of buying one for 98 dollars a foot premade - I placed all the beer lines around one of the vinyl tubes(which had been arbitrarily chosen to be the "cold fluid to the tower" line in a semicircle to keep them in contact with the cold fluid and keep down foam. I secured the return line to the back of the cold line and secured them all together with zip ties every few inches. I know that professional trunk lines have a plastic interior, so I decided to make the interior easier to work with and try to stop condensation by wrapping the entire thing in saran wrap. worked pretty well and made getting the foam closed up easier than it could have been.

The foam had two self adhesive sides that stuck together to hold the tubing shut, I wanted more than that so I decided a wrapping with electrical tape would help - and it did. It made feeding the line through the hold I cut to the basement a lot simpler and rip free. I even had my son help me do it - and telling an 11 year old what to do with something like this while you yell commands and directions through the living room floor is not supposed to be as easy as it was.

EDIT: I had one of the QD posts break off of the bev seal line and tried the boiling water thing to fix it( which involved a jet boil stove, a headlamp and me burning my fingers and some arm hair. I bought a heat gun for $20 from True value which made working with the tubing so much easier. A heat gun is a must for anyone using this tubing.