You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

High efficiency Guys

- Thread starter DonH

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

The old timers used to write that efficiency didn't matter, and chasing it is a fool's game. Meh, I chased it lots.

Turns out they were right, haven't figured out my efficiency in several years. I'm not criticizing anyone doing it, I think it's great to dig into the numbers, but in the end you'll find that it won't change much and you won't care much either.

Turns out they were right, haven't figured out my efficiency in several years. I'm not criticizing anyone doing it, I think it's great to dig into the numbers, but in the end you'll find that it won't change much and you won't care much either.

The old timers used to write that efficiency didn't matter, and chasing it is a fool's game. Meh, I chased it lots.

Turns out they were right, haven't figured out my efficiency in several years. I'm not criticizing anyone doing it, I think it's great to dig into the numbers, but in the end you'll find that it won't change much and you won't care much either.

Advertising your age, I see

I'm definitely interested in my efficiency numbers. My grain source is a bit more sketchy than the professional stuff most of you guys are using, and my efficiency numbers have tended to fall in the 60's, but in one case (ironically my biggest beer) broke 80%. My intention with keeping an eye on efficiency is to get a better idea of what I should expect on a typical brewday so I can calculate my grainbills accordingly.

Chasing high efficiency might be a sort of white whale, but I can definitely see the appeal, especially for BIAB. If I'm getting 60% efficiency and the OP is getting 85%, he can make much bigger beers with the same-size kettle, where I have to spend more on grain and would be forced to do two separate mashes for the same results on some big beers. It's not necessarily worth losing any sleep over, but it's worth some consideration.

cluckk

Well-Known Member

I've been hitting mid-80's since I started grinding my own grain. I calculate it with BeerSmith just for repeatability reasons, and to warn me when something went wrong.

Of course, with efficiency the most important thing is consistency. To get a mid-80's once in a blue moon does you little good. I say this because I had those times in the past where for some unknown reason everything seemed to go just right and I would get 80% and the next time I made the same identical batch would get 65%. Such wide swings made it impossible to know what a batch would come out as. It is better to hit 65% every batch than to hit somewhere between 65 and 90 with no way of knowing which will happen. The regular 65% guys can calculate for a known factor. Those whose systems are inconsistent have no idea.

Of course, with efficiency the most important thing is consistency. To get a mid-80's once in a blue moon does you little good. I say this because I had those times in the past where for some unknown reason everything seemed to go just right and I would get 80% and the next time I made the same identical batch would get 65%. Such wide swings made it impossible to know what a batch would come out as. It is better to hit 65% every batch than to hit somewhere between 65 and 90 with no way of knowing which will happen. The regular 65% guys can calculate for a known factor. Those whose systems are inconsistent have no idea.

I usually hit between 80-85% mash efficiency depending on the grain bill. Larger beers I get less lighter beers I am usually in the ball park of 85%

The biggest change to get more consistency was definately the purchase of a grain mill. Knowing I'm getting a consistent grind has definitely led to more consistent mash efficiencies.

Sent from somewhere to someone

The biggest change to get more consistency was definately the purchase of a grain mill. Knowing I'm getting a consistent grind has definitely led to more consistent mash efficiencies.

Sent from somewhere to someone

pablosbrewing

Well-Known Member

Just curious of how many guys are hitting 85%<

I just ended my brew day coming in at 89% according to Brewers-Friend and on my new equipment! I'm beyond happy right now. I brewed a Belgian Chocolate porter

I'm curious - full volume in kettle and just drain the bag or are you sparging the bag? What was your water to grain ratio in the mash.

My boil off rate is pretty high (2 gal/hr) so maybe my mash is too thin (2.6qt/gal last batch).

I've been running 65-70% with LHBS roller mill (single crush), mashing 148-149F for 90 minutes, stir every 15 minutes. Getting great beer but if I can get a little more efficiency that would be great.

full volume in kettle, mashing 150-152, 60 minute. running pump as recirculation. 1.9lbs of grain per 1 gallon of water on this beer

my boil off rate came out to .75gal so nowhere near your boil off rate....

my boil off rate came out to .75gal so nowhere near your boil off rate....

BIAB + sparge 5-15 gallon batches at 80%-85% been achieving 83% for the last 18 batches. I use a JSP mill at .034 crush, mash in 167* mash temp at 150 for 60-90mins Iodine check for starch conversion, etc.

Once a month I teach a BIAB method of brewing, I replaced my old 2 kettle and cooler for BIAB which I love.

Once a month I teach a BIAB method of brewing, I replaced my old 2 kettle and cooler for BIAB which I love.

- Joined

- Apr 13, 2013

- Messages

- 1,983

- Reaction score

- 958

I view efficiency as important for two main reasons: (1) to be able to accurately and repeatably predict what I will be getting brew after brew, and (2) to help determine/troubleshoot any process issues when I don't get within an acceptable range. Doing BIAB, my process is consistently in the 85% to 87% efficiency range. While I didn't specifically try for a high efficiency, I did work for consistency and that is where it seems to repeatedly end up. It allows me to repeat a recipe and have confidence that that part of the process will give me the same results as the previous times I brewed it.

Gameface

Well-Known Member

I'm now reluctantly setting my BS efficiency at 83% because that's where it's been since I set my gap a little tighter and started using a bit of acidulated malt. Before that I was pretty solid at 76%.

I just want to know where I'm at. 83% makes me pretty happy if I can hit within a few points of that every brew day. I have no desire to chase a bigger number for the sake of a bigger number.

I just want to know where I'm at. 83% makes me pretty happy if I can hit within a few points of that every brew day. I have no desire to chase a bigger number for the sake of a bigger number.

wobdee

Junior Member

With my crush set at the size of a credit card I've been getting consistent 85% efficiency with full volume BIAB 3 gal batches. I've also experimented with sparging and have seen efficiencies as high as 95% but it seems a little less consistent than full volume no sparge.

Sent from my iPhone using Home Brew

Sent from my iPhone using Home Brew

loads of good info so far! And for those who argue efficiency is a waste, why so? As a new brewer I would like to know if I am utilizing my tools properly an not wasting a grain bill as a friend of mine nailed an all time low of 52% hah!

As everyone else has stated, consistent efficiency is the most important thing. I just switched a new mill, and a looser gap bumped my efficiency up by 10% (old BC vs my new MM2-2.0) so I'll be monitoring my efficiency more closely for the next couple of brew days.

wobdee

Junior Member

Something I've noticed with this super fine crush is a lot of flour in the kettle. Lately I've been skimming it out prior to boil but I don't know if that makes a difference or not. I have thought about adjusting to a coarser grind but then I think my efficiency consistency will suffer and I don't mind skimming the crud out.

I usually hit 65% and crushing my own grain. Do you calculate the efficiency prior to the start of the boil? Still a bit of a Newbie to the BIAB, although I have several batches under my belt I am always looking for ways to improve my own process. I do crush my own grain but I think I need to get the mill a little tighter... I am starting think the efficiency doesn't matter since I hit my OG everytime (sometimes a tab higher) so does it really matter?

- Joined

- Apr 13, 2013

- Messages

- 1,983

- Reaction score

- 958

I usually hit 65% and crushing my own grain. Do you calculate the efficiency prior to the start of the boil? Still a bit of a Newbie to the BIAB, although I have several batches under my belt I am always looking for ways to improve my own process. I do crush my own grain but I think I need to get the mill a little tighter... I am starting think the efficiency doesn't matter since I hit my OG everytime (sometimes a tab higher) so does it really matter?

If your system is consistent and predictable, and it sounds like it is, you are in very good shape. You may get a little more value out of your grains with and increase in efficiency, but you will have to prove your process out again. Bottom line is: if you are happy with what you are getting, keep on doing what you have been doing!

I usually hit 65% and crushing my own grain. Do you calculate the efficiency prior to the start of the boil? Still a bit of a Newbie to the BIAB, although I have several batches under my belt I am always looking for ways to improve my own process. I do crush my own grain but I think I need to get the mill a little tighter... I am starting think the efficiency doesn't matter since I hit my OG everytime (sometimes a tab higher) so does it really matter?

Try a batch or 2 with your mill set tighter and calculate the efficiency for each batch. If it improves, then you can adjust recipes to account for the increased efficiency. Efficiency isn't terribly important until you think about the extra cost of grain you have spent when you are doing your hundredth batch. Now that I'm getting a consistent 85% efficiency, I'd be appalled to see a 65% efficiency again.

Try a batch or 2 with your mill set tighter and calculate the efficiency for each batch. If it improves, then you can adjust recipes to account for the increased efficiency. Efficiency isn't terribly important until you think about the extra cost of grain you have spent when you are doing your hundredth batch. Now that I'm getting a consistent 85% efficiency, I'd be appalled to see a 65% efficiency again.

RM-MN, will do, was planning on grabbing some thickness gauges at HD before my next batch which will be an imperial stout 3.5 gallon batch. It has a huge grain bill so this will be quite an undertaking but looking forward to it!

Do you have a picture of what your crush looks like? Or anyone that gets 85+ efficiency for that matter? I would like to compare and contrast and see if this helps some of newbies

RM-MN, will do, was planning on grabbing some thickness gauges at HD before my next batch which will be an imperial stout 3.5 gallon batch. It has a huge grain bill so this will be quite an undertaking but looking forward to it!

Do you have a picture of what your crush looks like? Or anyone that gets 85+ efficiency for that matter? I would like to compare and contrast and see if this helps some of newbies

I tried to get a picture but the cheap camera that works so well for outdoor pictures gave me such a blurry picture of the grains that I couldn't tell what it was except that I remember when I took the picture. I use a Corona style mill and I have it set as tight as I can get it. The husks are ripped to shreds and the grain looks like cornmeal and flour mixed. It works out well for BIAB but it would be impossible in a conventional tun.

Terek

"Did I just drop down a rabbit hole?"

I always do an eff. Reading on every batch. It lets me know what is happening, and if stuff is working right. I usually get 75% with a batch sparge. One day I found I got a 60% and started going threw my stuff. After picking threw my equipment with a fine tooth comb, I found that my digital thermostat was now reading 20* higher. So instead of mashing at 154*, I really mashed at 134*..... Yikes! I find that you should always check eff. And gravity just to make sure everything is fine. Things break, especially when there is water, and hot water esp., involved. Unfortunately that thermometer cannot be re calibrated, so in the trash it goes. 30$ down the drain, but it's better than not knowing. I was surprised that during a conversation with my LHBS owner, that she says that a good 50% of people don't check with a hydrometer! let alone eff. My jaw dropped......if you are gonna spend all this money and time to make something great and of your own creation, you should at least know if you are making mistakes or not. Might as well let your kids brew it. Or buy beer......I think of home brew as an art. You wouldn't paint a painting with your eyes closed, would you?

thisisbeer

Well-Known Member

I would say good efficiency comes with good beer at least in some cases. By good efficiency i would say 70%+ in most cases. If your getting below that it probably has something to do with the water not being right for the grain bill. It's not the efficiency that makes bad beer. But much less than that and there is probably a reason your below 70%. Don't get me wrong when I started I was getting 60% -65% on most of my brews and they turned ok. But having all your variables where they need to will naturally put you in the 70%+ range. Sometimes it could be something as simple as the crush but I find a lot of times it's in the water.

donovanmaxwell

Well-Known Member

- Joined

- Dec 8, 2013

- Messages

- 89

- Reaction score

- 9

I just completed my first BIAB and hit 89% efficiency. I ended up mashing a little over 90 mins due to getting caught up with some household tasks with my wife. Double-ground the grains, full volume mash. Started mash @ 154° and it finished about 147°.Set bag in a colander and squeezed it like my life depended on it. We'll see how consistent I can be on the following batches..

Chasing after efficiency, without regard to quality and consistency is a mistake in my opinion. I desire consistency above all. If you have high consistency, high quality, and high efficiency in one package, you're some one the breweries are looking for. Best of luck.

Terek

"Did I just drop down a rabbit hole?"

I would say good efficiency comes with good beer at least in some cases. By good efficiency i would say 70%+ in most cases. If your getting below that it probably has something to do with the water not being right for the grain bill. It's not the efficiency that makes bad beer. But much less than that and there is probably a reason your below 70%. Don't get me wrong when I started I was getting 60% -65% on most of my brews and they turned ok. But having all your variables where they need to will naturally put you in the 70%+ range. Sometimes it could be something as simple as the crush but I find a lot of times it's in the water.

i belive this to be true. I did an ipa last weekend, and i crushed it so fine i almost pooped myself. usually when i do this, i get around 82-86%. I also us well water from my shop. This batch i used water strait from the small creek by my turkey hunting spot. The water is still good snow melt runoff. I hit 72% eff. on this one. I hit all my targets and had a flawless brewday. the only diff in my teqnique was the water, with a huge diff. in eff.

This is not to say I wont ever use the creek water again, every body LOVES my "Turkey Day IPA" and I make it every year

RM-MN, will do, was planning on grabbing some thickness gauges at HD before my next batch which will be an imperial stout 3.5 gallon batch. It has a huge grain bill so this will be quite an undertaking but looking forward to it!

Do you have a picture of what your crush looks like? Or anyone that gets 85+ efficiency for that matter? I would like to compare and contrast and see if this helps some of newbies

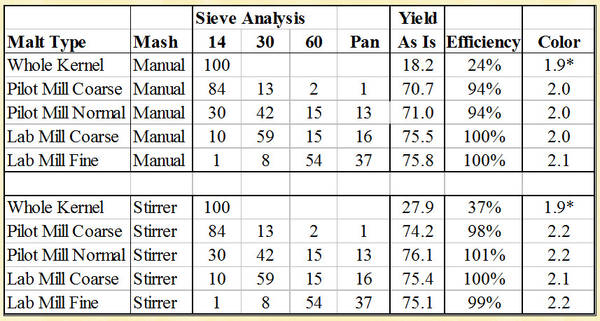

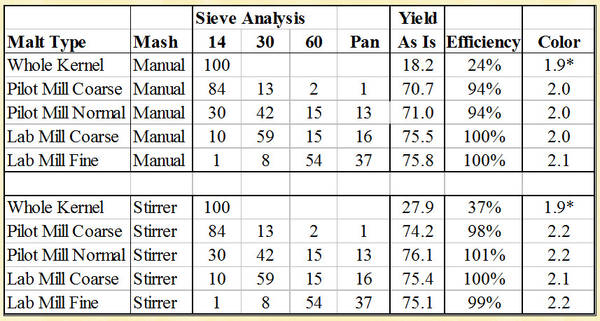

Briess evaluated efficiency vs. crush. They even looked at efficiency with unmilled grain! Anyway, the conclusion here was that for homebrewers the efficiency difference with almost any crush was very good. I think for homebrewer, the "Normal Grind" in the picture is typical.

Download the Powerpoint Named Practical Milling for the Craft Brewer from http://www.brewingwithbriess.com/Malting101/Technical_Presentations.htm

In the table below, Malt Type should be "Grind Fineness". You can see that for every grind, they got efficiencies over 90%. The low one is unmilled malt.

Briess evaluated efficiency vs. crush. They even looked at efficiency with unmilled grain! Anyway, the conclusion here was that for homebrewers the efficiency difference with almost any crush was very good. I think for homebrewer, the "Normal Grind" in the picture is typical.

Download the Powerpoint Named Practical Milling for the Craft Brewer from http://www.brewingwithbriess.com/Malting101/Technical_Presentations.htm

In the table below, Malt Type should be "Grind Fineness". You can see that for every grind, they got efficiencies over 90%. The low one is unmilled malt.

That's a nice table that Briess put out but I don't really believe it. First off I don't see how long they mashed and secondly, that second part of the table shows that they got 101% efficiency. The only way to do that is to add pure sugar.

That's a nice table that Briess put out but I don't really believe it. First off I don't see how long they mashed and secondly, that second part of the table shows that they got 101% efficiency. The only way to do that is to add pure sugar.

> 100% is possible in a lab setting (I've read this before).

We calculate efficiencies based on a potential extract from that grain (i.e. most are around 1.036 points per gallon). So, if we had perfect extraction from that grain, in 1g of water, we'd measure 1.036 in hour hydro and have 100% efficiency.

But where does 1.036 come from? You might suspect that chemical analysis of the grain determined that's the total possible soluble sugars in the grain. I don't think this is the case. It's a number that was empirically determined through trials using standard brewing equipment and processes. I think there's more sugars available and that potential extract number is higher. And, while I don't know how it's done, the lab is better at the extraction of sugars than we are in our garages.

So, anyway, maybe I agree there's some reason to question the paper I referenced. But at least it's a piece of real data from trials, and not just the conjecture and anecdote that we usually have as "evidence" for our decision.

BIAB + sparge 5-15 gallon batches at 80%-85% been achieving 83% for the last 18 batches. I use a JSP mill at .034 crush, mash in 167* mash temp at 150 for 60-90mins Iodine check for starch conversion, etc.

Once a month I teach a BIAB method of brewing, I replaced my old 2 kettle and cooler for BIAB which I love.

How much water do you use for sparging? What is your sparging method?

I just sparge 178* water till I reach my pre-boil level I have a dual ring (8 inch ring inside a 16 inch with #51 drill bit holes every half inch) takes around 30 mins to fill while coming up to boil temps.

Similar threads

- Replies

- 8

- Views

- 535

- Replies

- 11

- Views

- 789

- Replies

- 40

- Views

- 2K

- Replies

- 8

- Views

- 426

Latest posts

-

-

-

Flashing/grommets in side of refrigerator for beer and gas line?

- Latest: Spartan1979

-

-

-

-

-