I really like the design of your build and am planning on a set up similar to yours. Is there anything you would do differently if you were to start over besides the 40 amp SSVR?

I was also thinking of using reflectix instead of the keg skin.

I've only got two brews under my belt on this system, and while it all works, there are a few things that could be improved upon.

I *really* like the contoller - it's simple, compact, and it works well. The only minor thing is the non-linearity of the response to the potentiometer - it's really sensitive at the low end, making it a bit fiddly to dial in a specific output. Not a big deal at all, but worth noting.

One other thing about my controller - when I built it, I hadn't yet figured out how to mount it, and I guess I was thinking it would probably just lay on the brew stand next to the keggle. I oriented the heat sink with the fins front-to-back; now that I have the controller mounted upright, the orientation of the heatsink fins is suboptimal. And it does get hot when running at full power - not enough to burn on contact, but hot enough to where I can't just leave my hand on it indefinitely. Maybe a 40A SSVR wouldn't have to work as hard and would give off less heat?

The KegSkin looks cool and it must help, but I'd be lying if I said that the keggle will hold mash temp without any additional insulation. Today I brewed a Stone Levitation clone. BIABacus said that I should strike 163.4F to mash at 157F. I doughed in at 165F (after carefully stirring and making damned sure the temperature of the strike water was consistent throughout) and by the time I was done stirring, it settled at 158F. During the 30 minute mash, the temperature dropped 4 degrees, and as it went from 157 to 156 I applied a little heat (2 amps) for the duration (probably the last 15 minutes or so). The temperature bottomed out at 154, then rose back to 155 right before the end of the mash. I'm hoping I can find a low heat setting that just replaces the heat that is dissipating through the KegSkin, but I'm not there yet. Next time, I'll try to hit my mash temp exactly, then immediately set the heat to 2 or 2.5A and see how it works.

I may add (or switch to) Reflectix at some point, but I really like being able to remove the KegSkin for cleaning/storage.

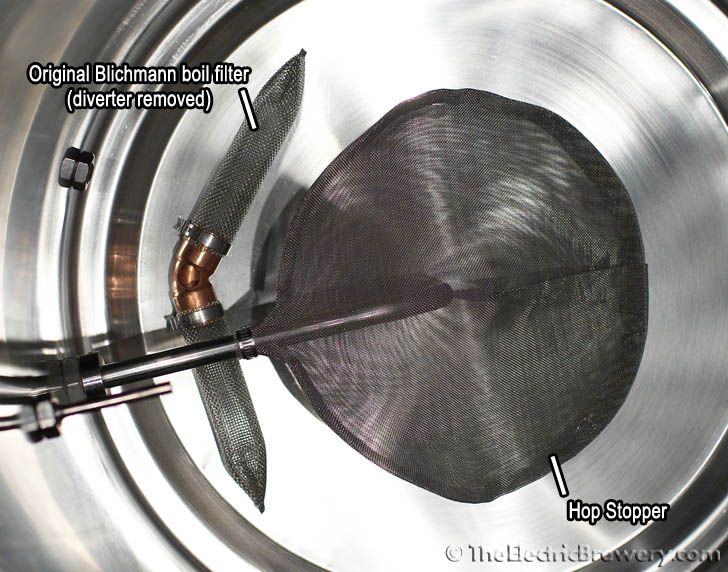

Finally, I still need to work out a better trub filter. I used a hop bag today and that helped A LOT, but by the time I had run 5gal of hot wort into my no-chill corny keg it was running pretty slow. I still needed to collect some wort for my yeast starter; what I should have done was just let it trickle into my starter flask, but I got impatient and dislodged the filter (as I did last time) and was rewarded with 2 liters of trub. I let it settle and eventually was able to pour off 500ml of relatively clean wort for the starter, but it would have been much nicer to have a trub filter that could handle the load.

On the positive side: it works, it heats liquid very quickly, dialing in a rolling boil takes about a second, cleanup is a breeze, and pretty much everything can be stored in the keggle (I don't store the controller that way, but bet I could).