I've read through some threads covering the topic of recirculating pumps for ICs but no one seems to say what they would think would be an ideal rate of flow. I want to setup the pump in a cooler with ice water and recirculate through my IC. I've heard some say that too slow or too fast could reduce your chilling rate. I have no idea how to come up with the ideal rate. I have a 3/8" 25' stainless IC. I've been just hooking up the water hose but it is starting to warm up here in Houston.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ideal rate of flow for IC recirculating pump

- Thread starter Belmont

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Boerderij_Kabouter

Well-Known Member

Depends if you are going for efficiency or speed of cooling. The fastest way to cool is to move the largest mass of cooling liquid through the tubing. This may not be the most efficient way, but IMHO, who cares about efficiency. Faster flow equals faster cooling.

The argument that I was hearing was that if the fluid wasn't in the tubing long enough then it wouldn't have time to absorb the heat energy. I wasn't a physics major in college so I'm not going to pretend to know this. I am much more concerned with faster cooling than efficiency as well.

Boerderij_Kabouter

Well-Known Member

What those people are talking about is heat absorption per unit of water. Some people get really bugged by wasting water so they want to have a slow flow rate to maximize efficiency.

But to cool the fastest, you want to maximize the mass flow of the cooling liquid to create the largest potential for eat removal.

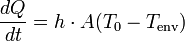

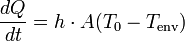

Basically what this says is that heat transfer depends on temperature differential between your body to be cooled (To) and the cooling medium (Tenv). To get To we are assuming that the heat transfer through the tubing is constant (this is the SS vs. copper debate, it is insignificant because of the thin wall thickness we are working with) so we assume To is he temperature of our wort. Tenv is provided by the cooling water. To be fastest, the cooling water should be at the lowest temperature attainable, this means flowing the water through as rapidly as possible. Area obviously increases cooling capacity and a larger area will decrease cooling times.

I have wanted to make a spreadsheet for cooling times for a while but have not taken the time to dig out my textbooks and figure it out.

But to cool the fastest, you want to maximize the mass flow of the cooling liquid to create the largest potential for eat removal.

Basically what this says is that heat transfer depends on temperature differential between your body to be cooled (To) and the cooling medium (Tenv). To get To we are assuming that the heat transfer through the tubing is constant (this is the SS vs. copper debate, it is insignificant because of the thin wall thickness we are working with) so we assume To is he temperature of our wort. Tenv is provided by the cooling water. To be fastest, the cooling water should be at the lowest temperature attainable, this means flowing the water through as rapidly as possible. Area obviously increases cooling capacity and a larger area will decrease cooling times.

I have wanted to make a spreadsheet for cooling times for a while but have not taken the time to dig out my textbooks and figure it out.

illin8

Well-Known Member

All things being equal, I don't think there is much of a difference if you are using a closed recirculating system...provided you maintain the ice/chilled water going in.

Boerderij_Kabouter

Well-Known Member

This is true. Temperature of the cooling water and the turbulence of the wort are the two limiting factors for cooling speed.

Similar threads

- Replies

- 44

- Views

- 1K

- Replies

- 0

- Views

- 613