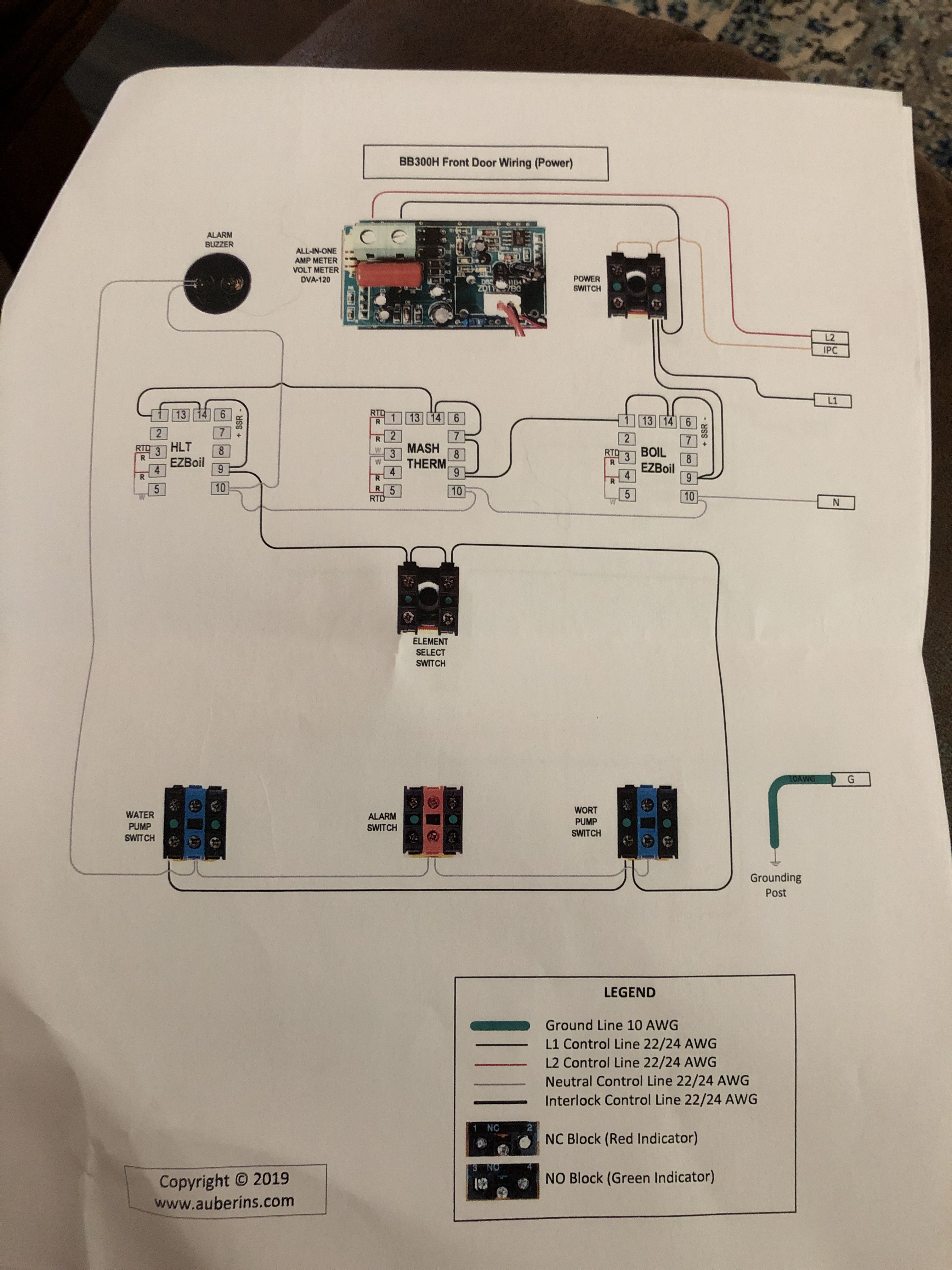

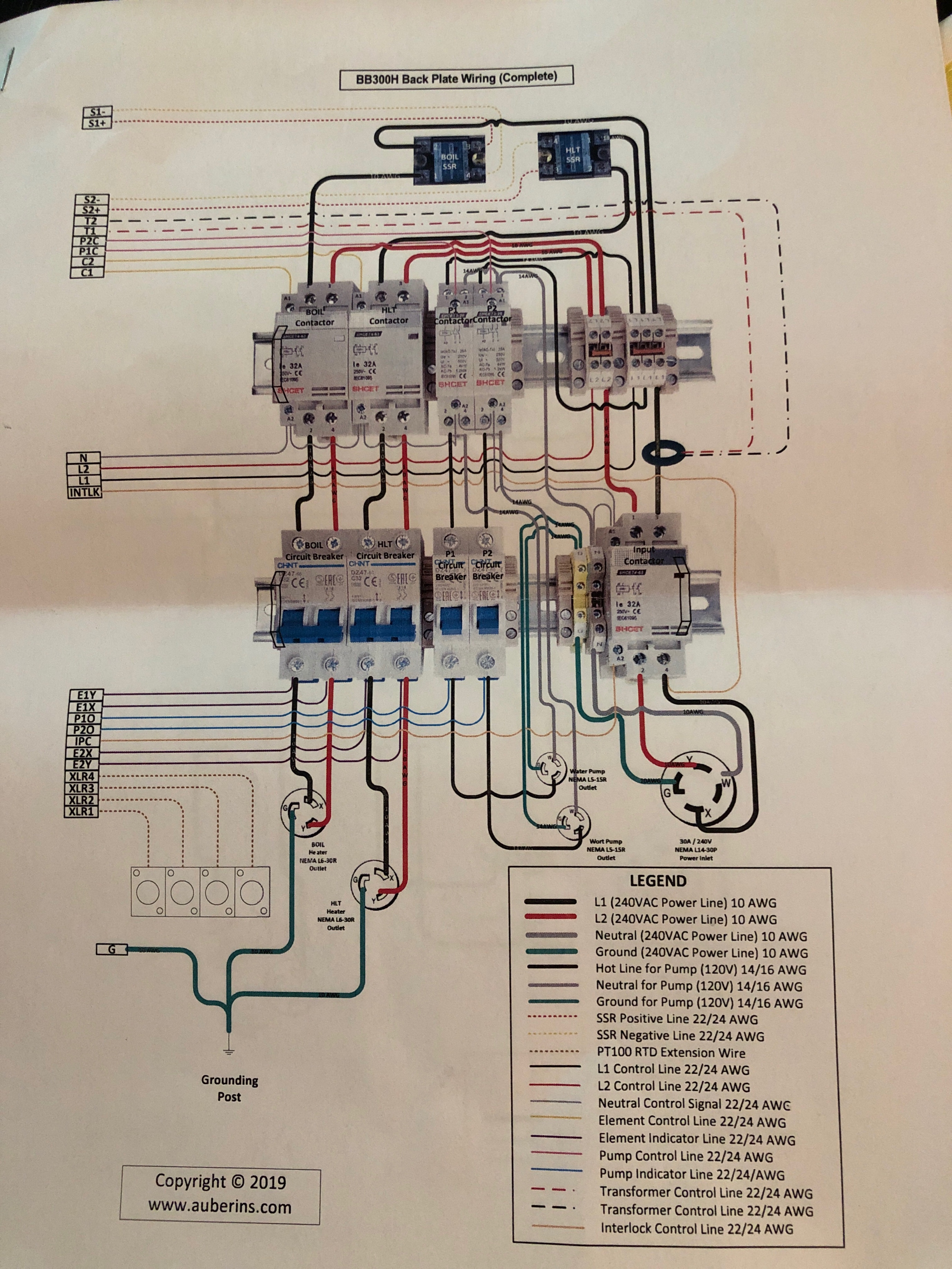

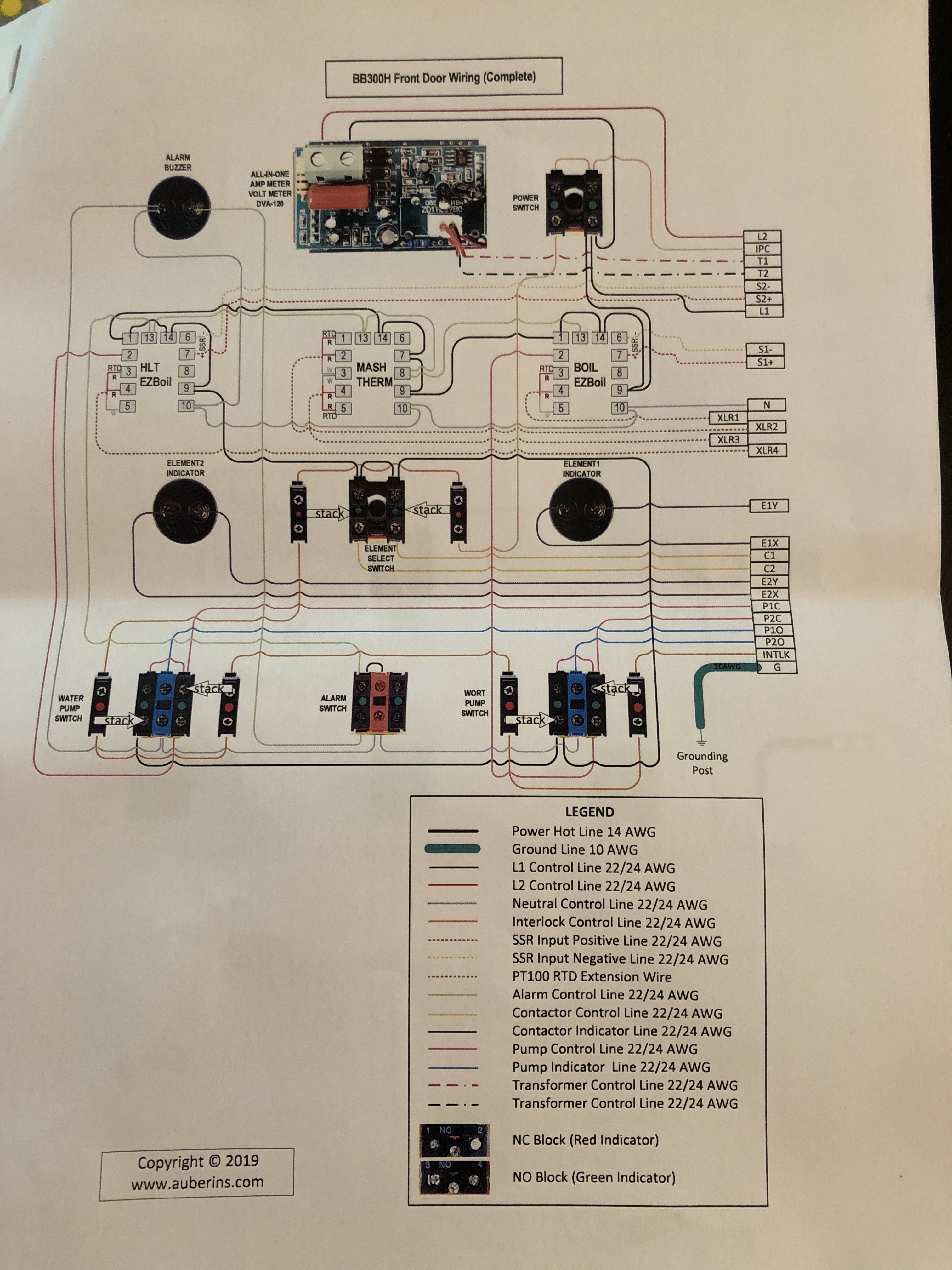

So I finally got my panel working. Everything seems work perfectly except for the pump switches.

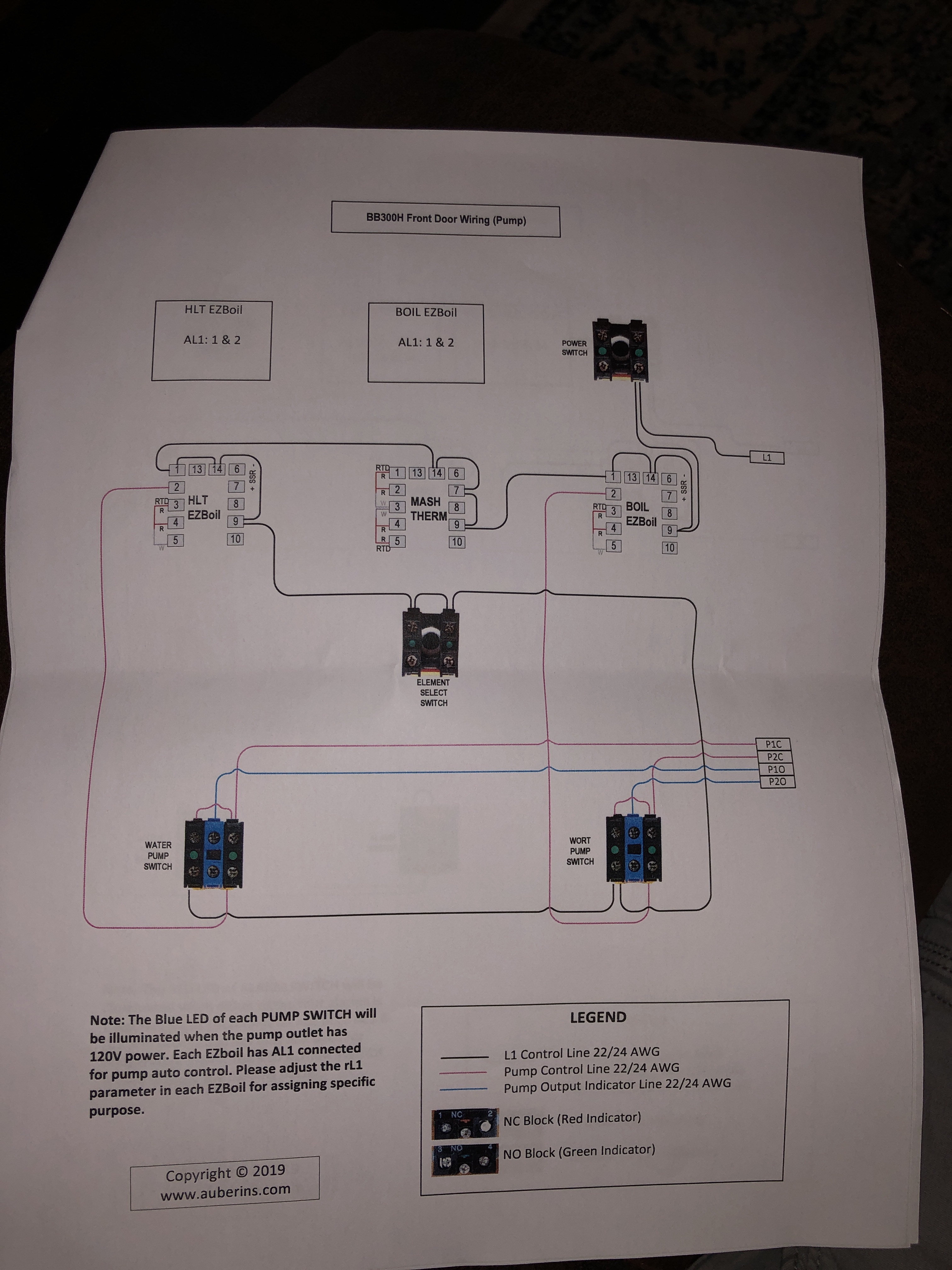

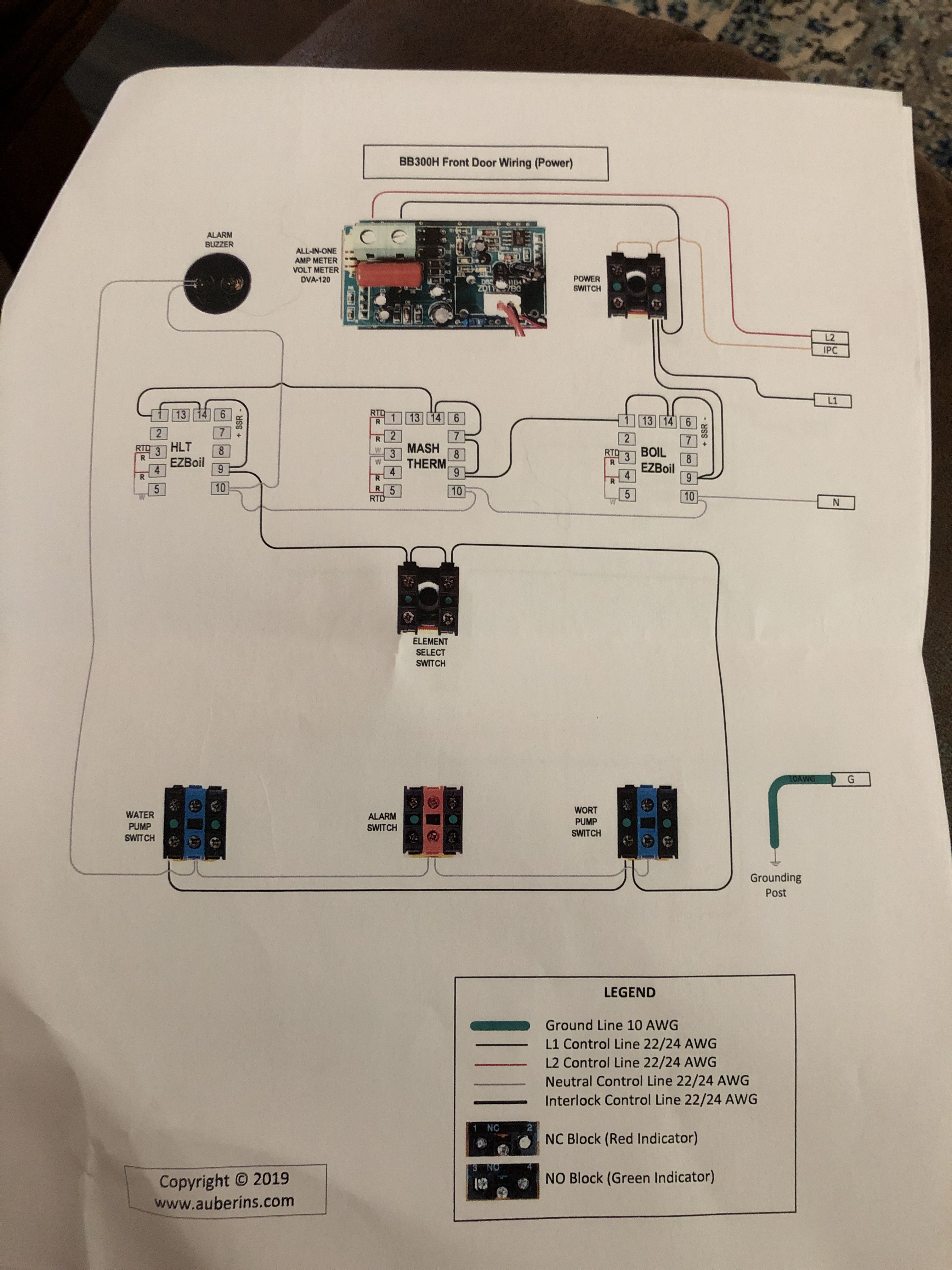

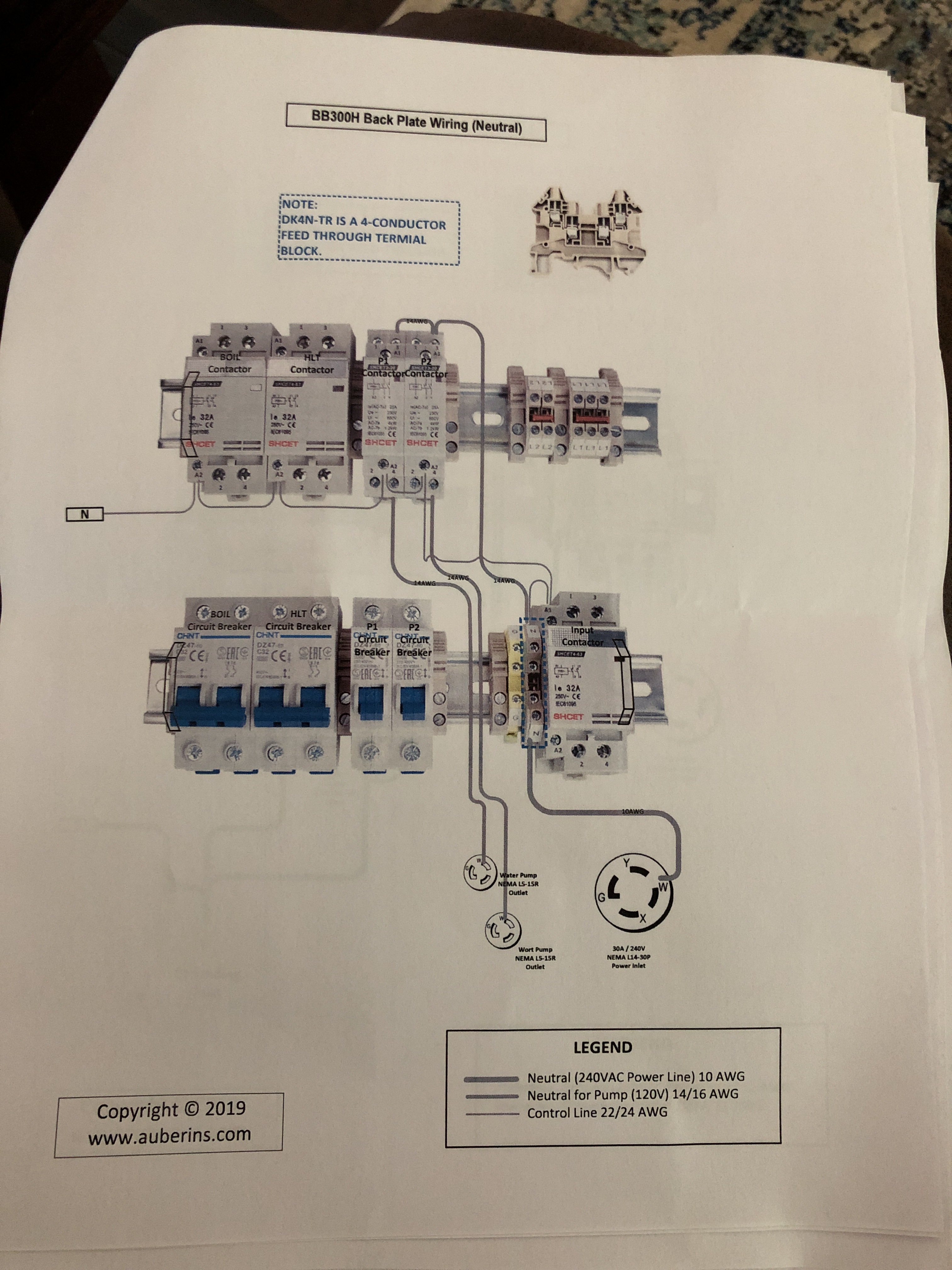

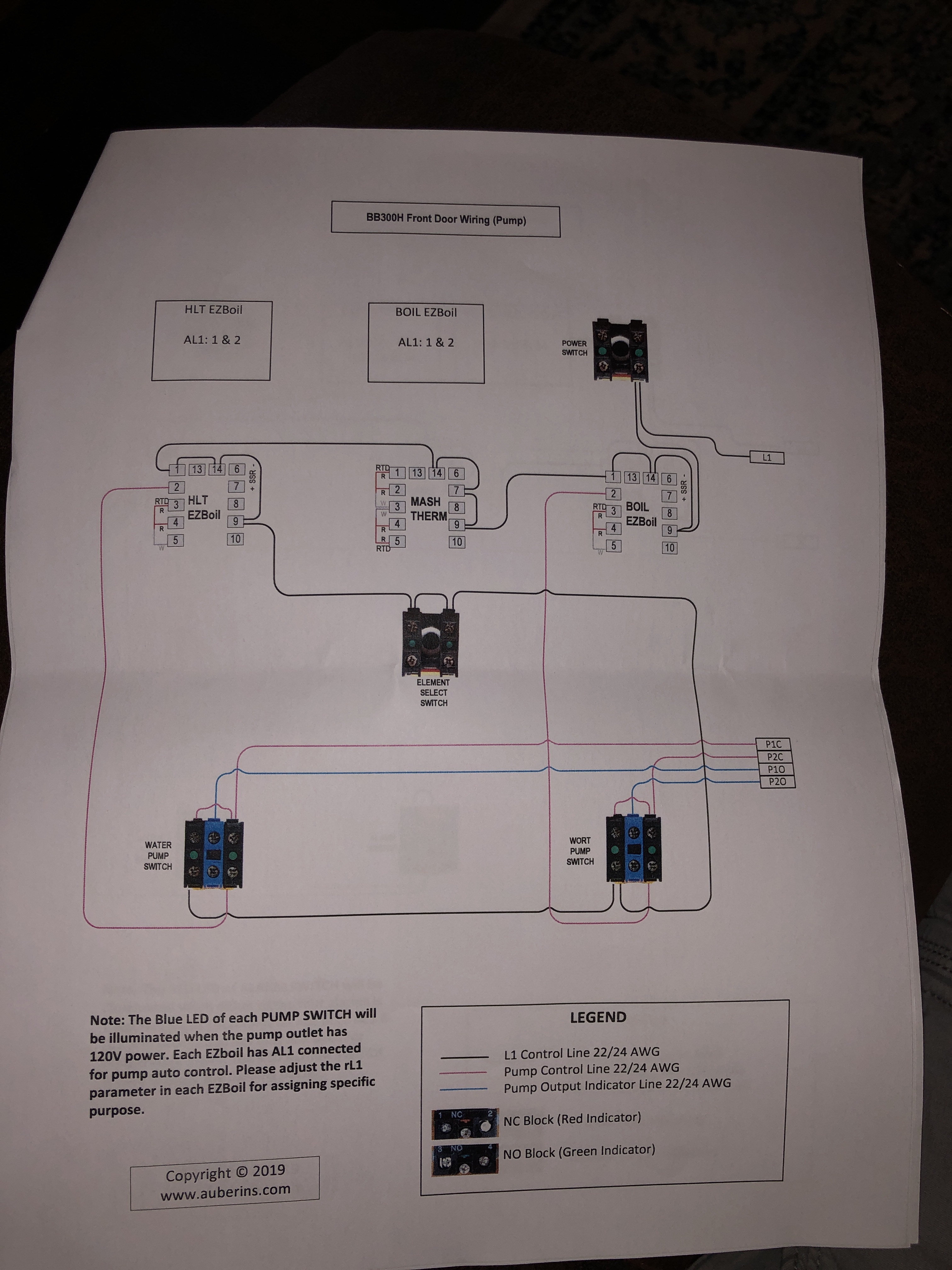

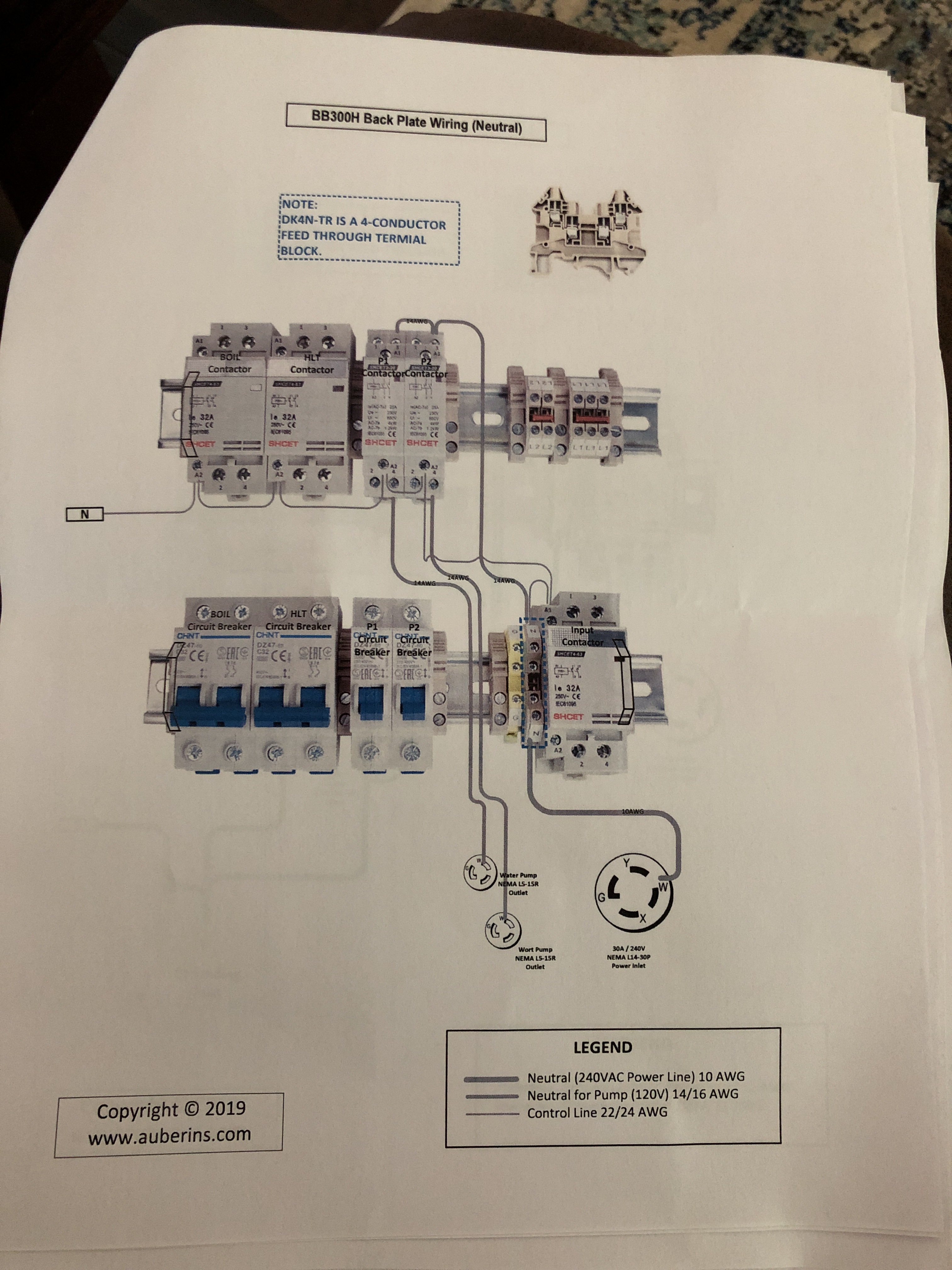

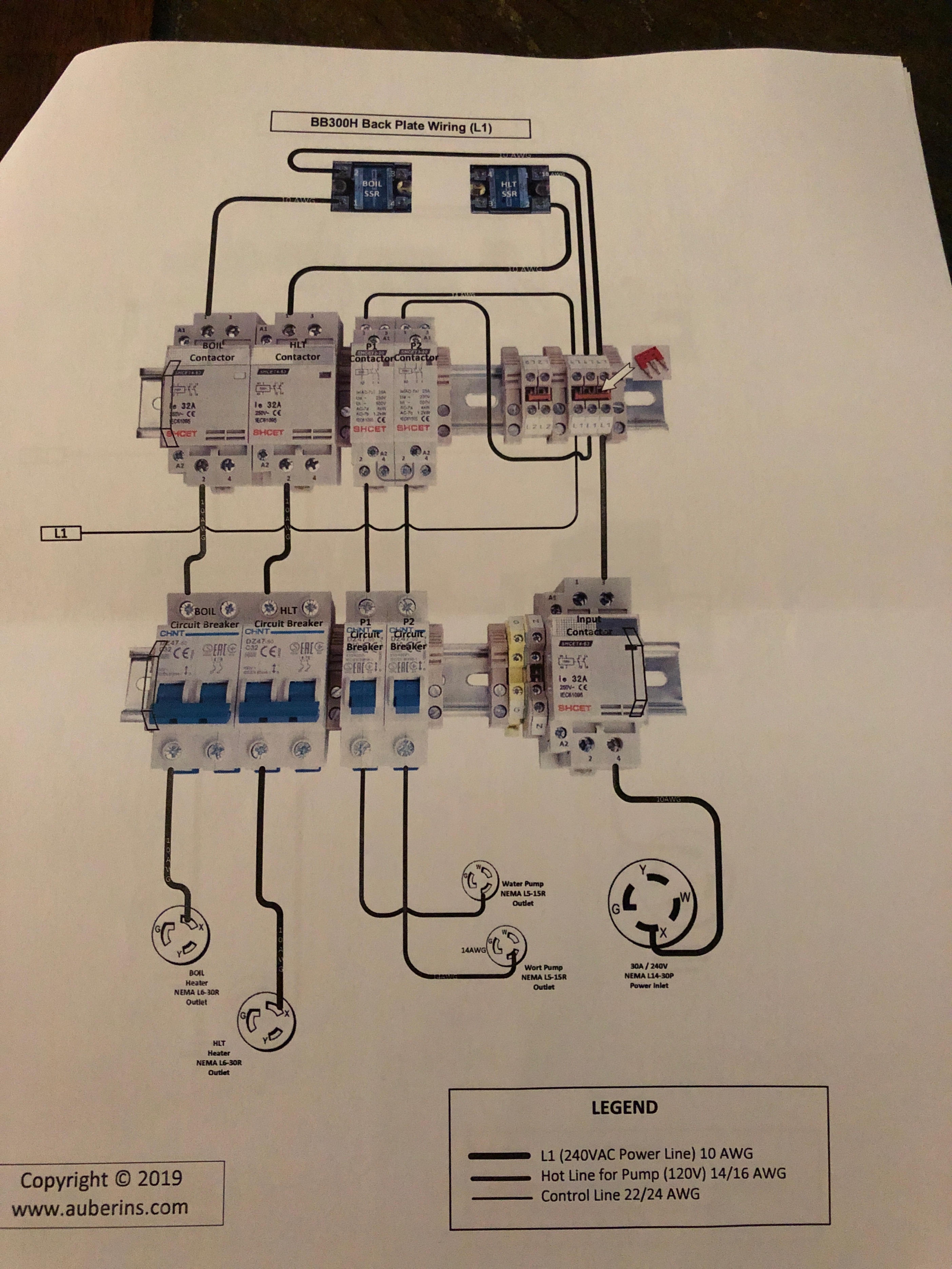

I can't turn either pump on unless both pumps switches are turned on and then when both switches are on, both pumps run. So I can't operate them individually.

Both contactors fire individually when I turn the appropriate switch and I have verified that I have 120v at the power output plug hot wire on each individual pump plug.

So I think that the issue is with the neutral line but I can't figure out what it is. I'm going to try replacing the contactors in case there's something wrong with them, but they both seem to be functional.

Any ideas would be appreciated!

I can't turn either pump on unless both pumps switches are turned on and then when both switches are on, both pumps run. So I can't operate them individually.

Both contactors fire individually when I turn the appropriate switch and I have verified that I have 120v at the power output plug hot wire on each individual pump plug.

So I think that the issue is with the neutral line but I can't figure out what it is. I'm going to try replacing the contactors in case there's something wrong with them, but they both seem to be functional.

Any ideas would be appreciated!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)