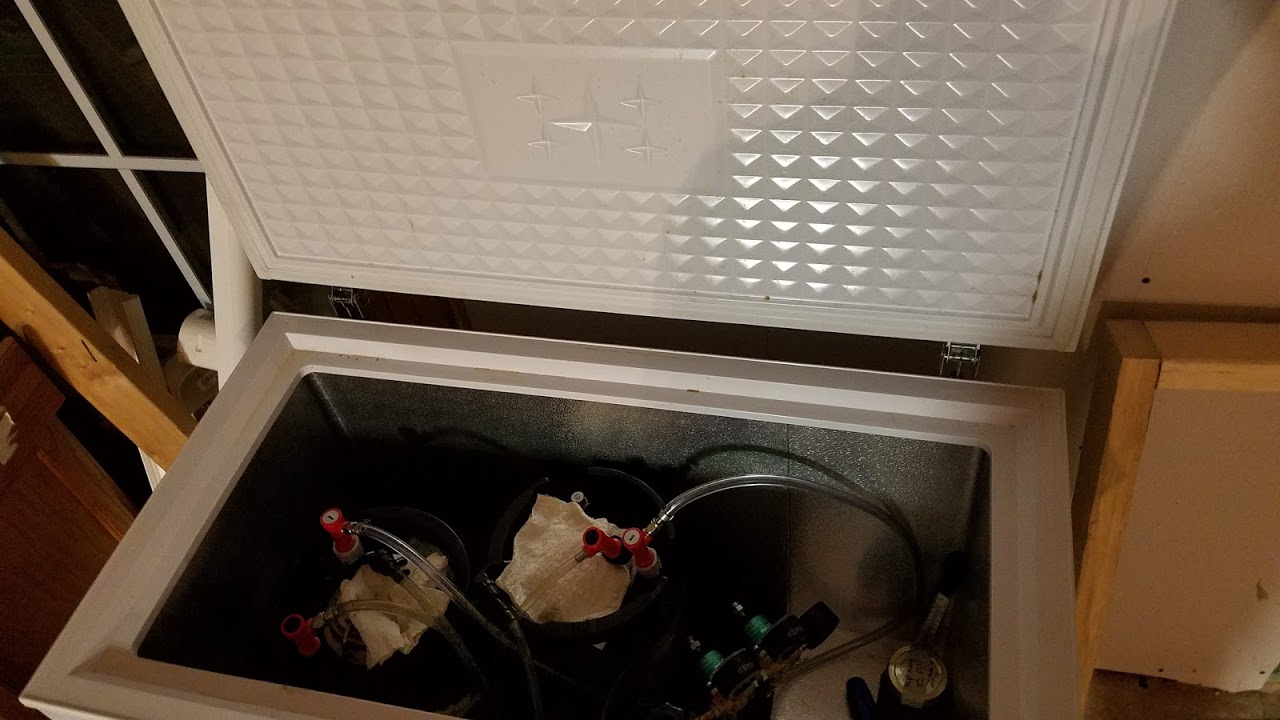

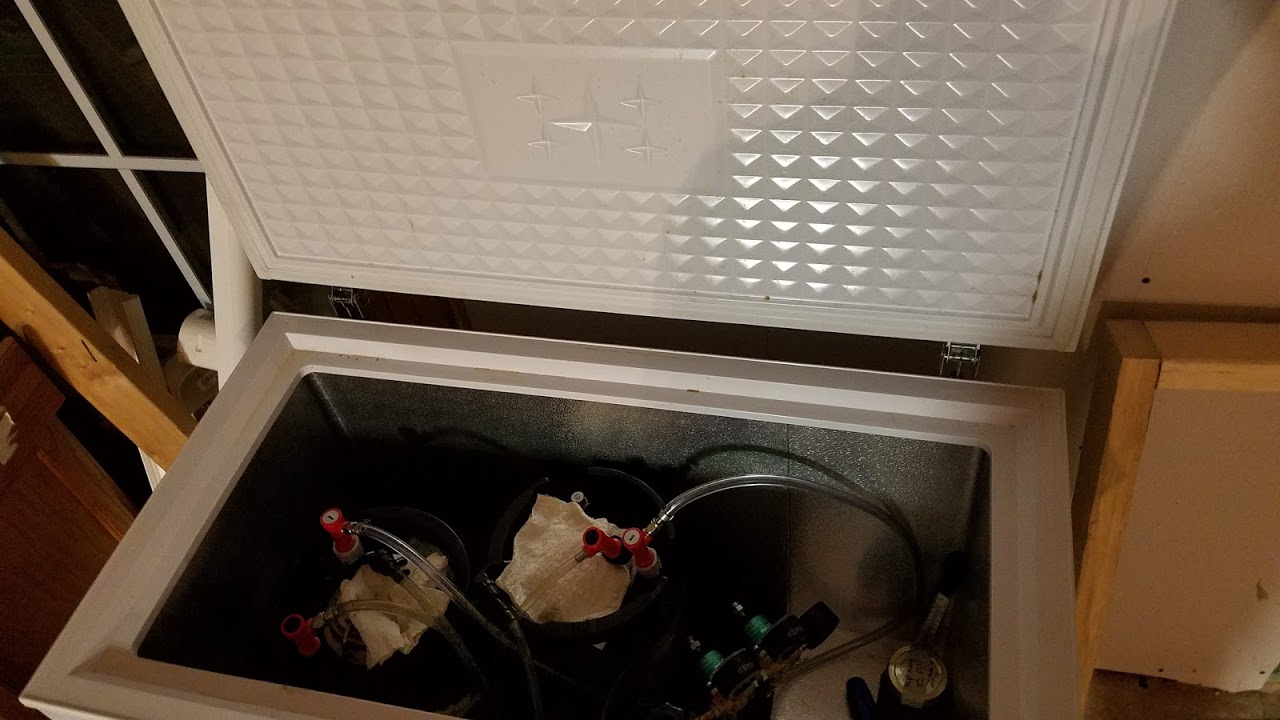

After stupidly waiting a year with the completely worthless picnic taps I finally decided I actually needed to finish this. I started a year ago with the freezer, I should have gotten a bigger one, but oh well... the one for the basement bar will be better... this is just for upstairs.

7.1CF... built the frame out of 2x4s. I had some 4/4 walnut I didnt know what to do with, so made the top out of that. I was going to use the lid, but I figured if I ever wanted to use the freezer again I would need it...I adj the internal temp sensor to about 37 degrees... hoping thats good enough without ext controller...

made the main body out of 1/4 poplar I think I will stain to match the walnut top... I was going to epoxy the top and put some grains or something in it, but I came up with a different Idea... so will see how it goes...

Still debating on how big the coffin top has to be, there are only 3 kegs so just 3 taps... i figure about 4 in between taps? I am using perlick 630ss...

some small tiles for the back splash and led lighting for the top...

this is in progess, and it might be slow...

7.1CF... built the frame out of 2x4s. I had some 4/4 walnut I didnt know what to do with, so made the top out of that. I was going to use the lid, but I figured if I ever wanted to use the freezer again I would need it...I adj the internal temp sensor to about 37 degrees... hoping thats good enough without ext controller...

made the main body out of 1/4 poplar I think I will stain to match the walnut top... I was going to epoxy the top and put some grains or something in it, but I came up with a different Idea... so will see how it goes...

Still debating on how big the coffin top has to be, there are only 3 kegs so just 3 taps... i figure about 4 in between taps? I am using perlick 630ss...

some small tiles for the back splash and led lighting for the top...

this is in progess, and it might be slow...

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)