Hello folks,

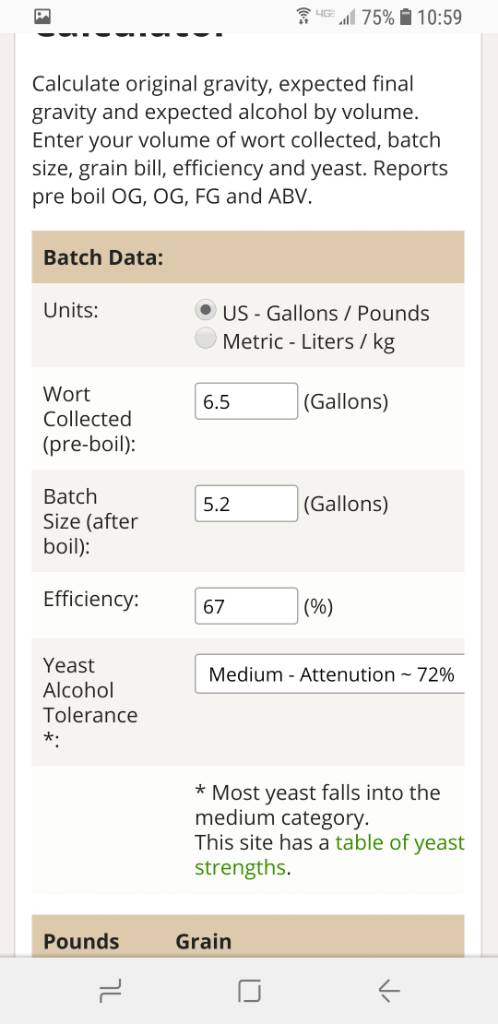

I brewed an amber ale 12 days ago (1.048 OG). Pitched WLP007. Just checked the SG and got a reading of 1.018. Yeast pitched at ~68° and beer has been fermenting in temp controlled chamber at 68°. Still minimal activity in the airlock. Everything I have read that strain eats up sugars and finished out pretty quick. Not here.

Do you think I should wait it out a while or go ahead and add some type of yeast nutrient?

I have brewed with WLP001 and WLP004 10 days ago and 5 days ago respectively and those are both already down to 1.011. Thanks

I brewed an amber ale 12 days ago (1.048 OG). Pitched WLP007. Just checked the SG and got a reading of 1.018. Yeast pitched at ~68° and beer has been fermenting in temp controlled chamber at 68°. Still minimal activity in the airlock. Everything I have read that strain eats up sugars and finished out pretty quick. Not here.

Do you think I should wait it out a while or go ahead and add some type of yeast nutrient?

I have brewed with WLP001 and WLP004 10 days ago and 5 days ago respectively and those are both already down to 1.011. Thanks

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)