VikeMan

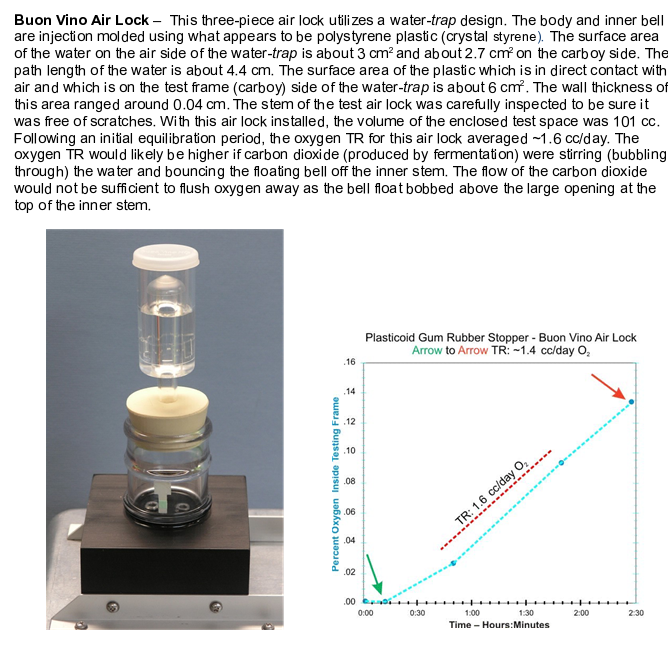

It ain't all burritos and strippers, my friend.

- Joined

- Aug 24, 2010

- Messages

- 5,963

- Reaction score

- 6,212

What I intended to say was a sealed chamber with an airlock, in a situation where the wort beneath is still emitting CO2, or to the point where it is no longer emitting but has no O2 ingress.

The problem is that once the CO2 "wind" stops, that airlock becomes a two-way street, with CO2 diffusing out and O2 diffusing in. Don't get me wrong...the fact that the O2 has to work it's way through a bit of vodka or starsan or whatever is better than a dry opening, but it's not the same as a sealed vessel. At that point, the CO2 barely matters (except for any random collisions that happen to bounce O2 molecules temporarily away from the beer, which delays the inevitable, but only for a little while).

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)