Finlandbrews

Well-Known Member

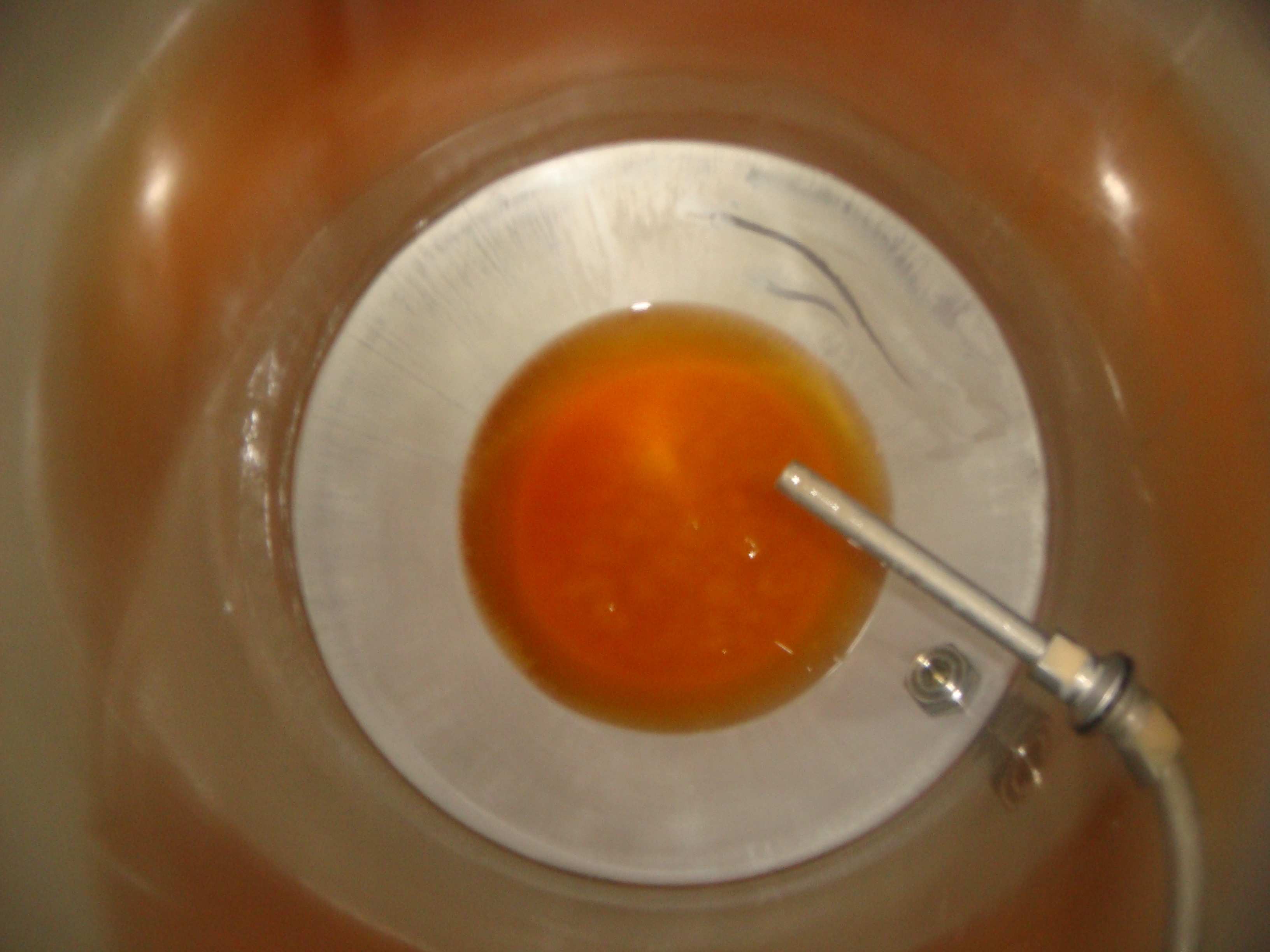

I have bought a 15 gallons kettle from ss brew tech and they recommend cleaning with tri-sodium phosphate when it is for first time use. Why is it so? I only have pbw and starsan... Should I buy tri-sodium phosphate?

View attachment 1447519799362.jpg

View attachment 1447519799362.jpg