brauhausjoe

Well-Known Member

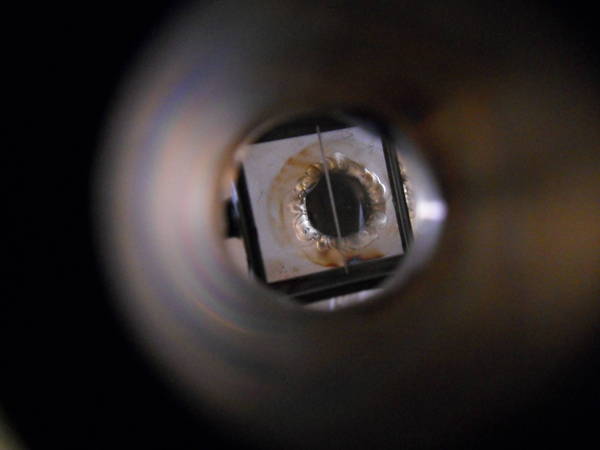

I have seen many pictures of the outside weld on keggles. I have see many pictures of the inside of Bad Welds. But I aint never seen pictures of what "good" welds are supposed to look like. Read about it, but I, like so many others am a graphical guy......

Show us the inside weld of them keggles!

Here is mine:

Hope it is not to big

and yes the threads are good

Show us the inside weld of them keggles!

Here is mine:

Hope it is not to big

and yes the threads are good

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)