Been brewing for years, but this is a first for me.

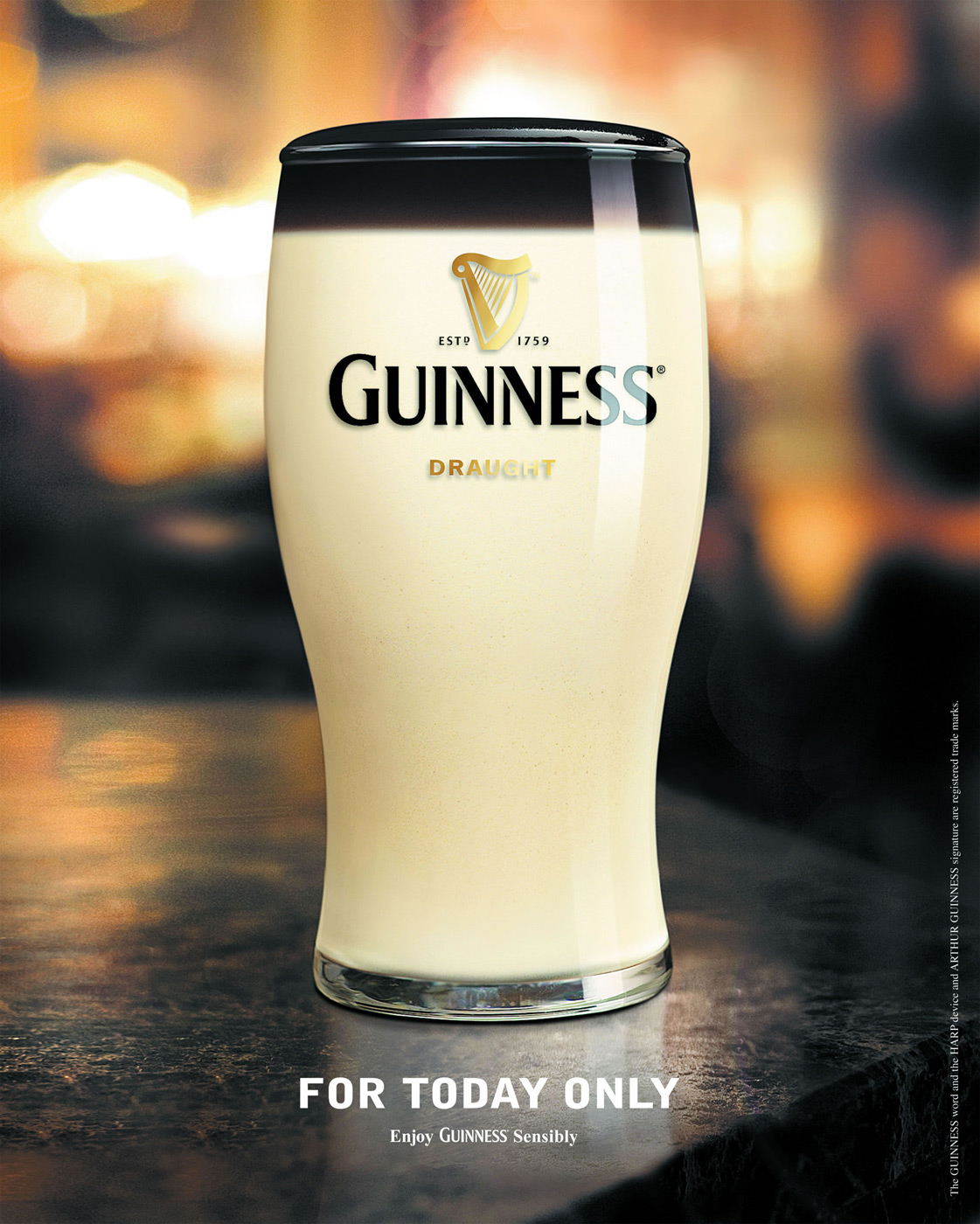

I made an all grain brew 3 months ago. It’s been fermenting since. About 2-3 weeks ago, I noticed that it was starting to turn black from the top down. The amount of black liquid is still getting bigger. Anyone have any idea what kind of infection/bacteria would cause this?

Pulled a sample. It smells a little like soy sauce to me. My wife disagrees. She thinks it smells like fermented fruit. Taste is sour/winey/pungent.

Here was my mash bill:

White wheat

Barley

Flaked barley

Rice hulls

Starting gravity was 1.072. Finish gravity was 1.010.

Could it be oxidation? Bacteria of some kind? Wild yeast? While it is a dumper, want to try to learn from it.

I made an all grain brew 3 months ago. It’s been fermenting since. About 2-3 weeks ago, I noticed that it was starting to turn black from the top down. The amount of black liquid is still getting bigger. Anyone have any idea what kind of infection/bacteria would cause this?

Pulled a sample. It smells a little like soy sauce to me. My wife disagrees. She thinks it smells like fermented fruit. Taste is sour/winey/pungent.

Here was my mash bill:

White wheat

Barley

Flaked barley

Rice hulls

Starting gravity was 1.072. Finish gravity was 1.010.

Could it be oxidation? Bacteria of some kind? Wild yeast? While it is a dumper, want to try to learn from it.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)