Welcomed a batch of new bottles. De-labeled and squeaky clean.

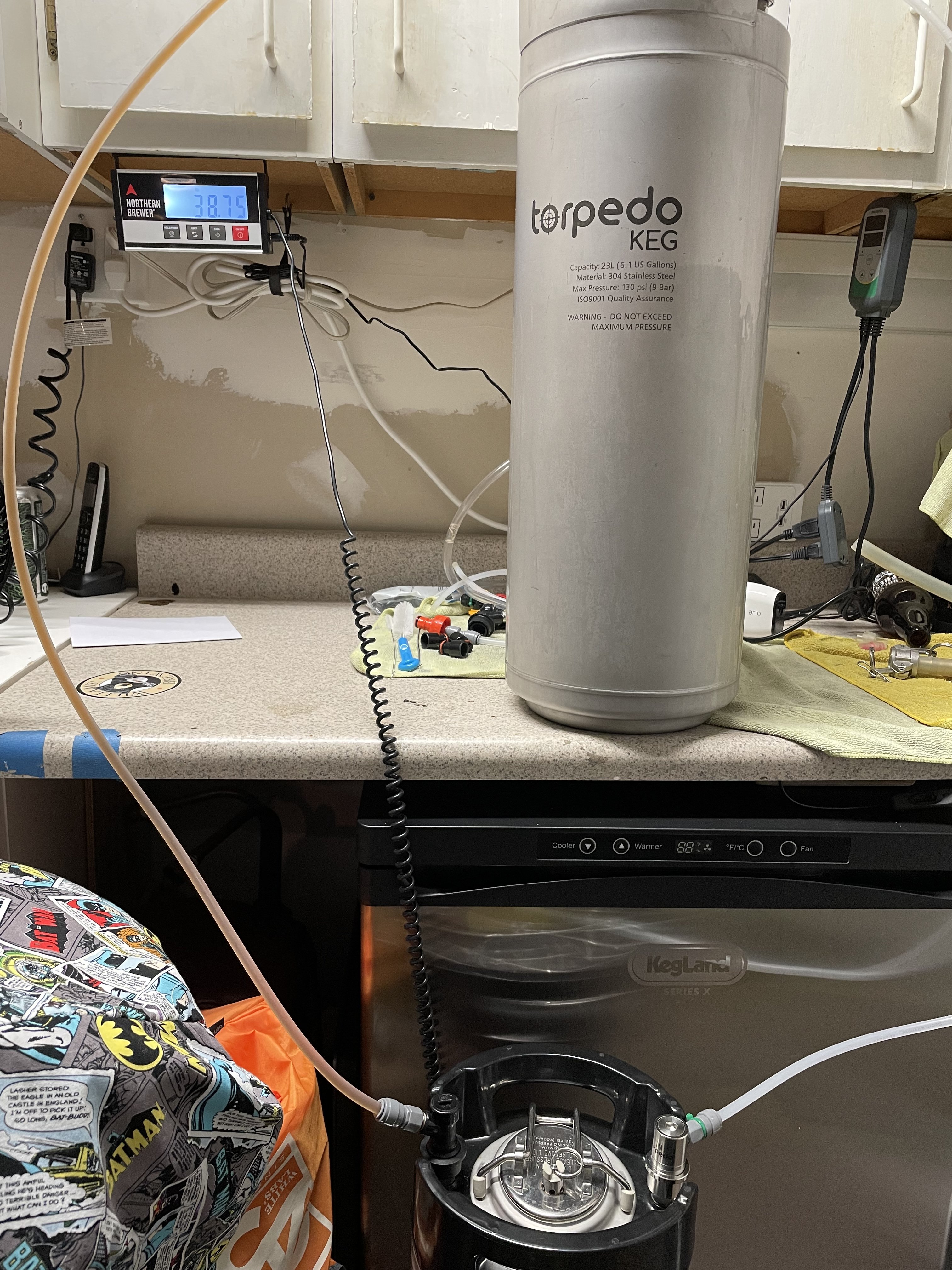

Checked the new CO2 system and found the new tank completely empty. Will head to the LHBS for a replacement tank as soon as he opens and will spend some time looking for the leak.

That's cool. Got a link?Nice ^

I bought a tandem quick disconnect that has a shut off valve in each side so I can disconnect my lines. Got this idea from Brian at Short Circuited Brewers, on his Youtube video.

John

Opening the door I found that one of the picnic taps had opened when I closed the door earlier.

I might have accidentally switched the FWH hops with the 10 minute addition.

Brett C, D, and Q? I guess we know your latest passion. May the yeast be with you!I got some new cultures in today. My first offerings from Escarpment labsView attachment 756839

Get well soon!Tasted some. Both my two coworkers tested positive for the 'rona on Sunday, I didn't get tested but I've probably got it, and just today got my smeller & taster back. Feel like absolute cr*p.