I did Dip Hopping for the first time.

Um, does this mean you added dip to a beer or you are packing hops between your cheek and gum?

I did Dip Hopping for the first time.

my supervisor has really come through with helping.

A rare sight, indeed.Stopped at Total Wine on the way home from work today and they apparently just got a visit from the Beerster Bunny. It's a Happy Easter!View attachment 726029View attachment 726030

Um, does this mean you added dip to a beer or you are packing hops between your cheek and gum?

Did you have any beer?I thought about beer all day at work a@aAAa*2£%££@1@*,@zaawhile I was looking at girls so then I came home and had some.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

Got bless my friendView attachment 726050

This is how I eat breakfast each morning. Jacket akimbo, silk napkin suggesting more, so much filthy more. Do you think a man like this would settle for common defilements such as oral tobacco use? Ha! I could tell you stories...such amazing stories. My old friend, Bob Ross, he had such amazing pillow talk...but you folk, you're always in such a rush. I miss Bob.

It's a new way to whirlpool hops that the Japanese figured out. Read the current issue of BYO to learn more. The quick and dirty virsion: Dump some hops in your empty fermenter, add either hot wort or hot water at around 170 (no body knows the ideal temperature yet, and, like whirlpooling, no body will likely ever know; also, nobody knows if wort or water is better--it's early days) and wait some number of minutes, then rack onto the disaster in the cone of your fermenter. Good things will happen, they say.

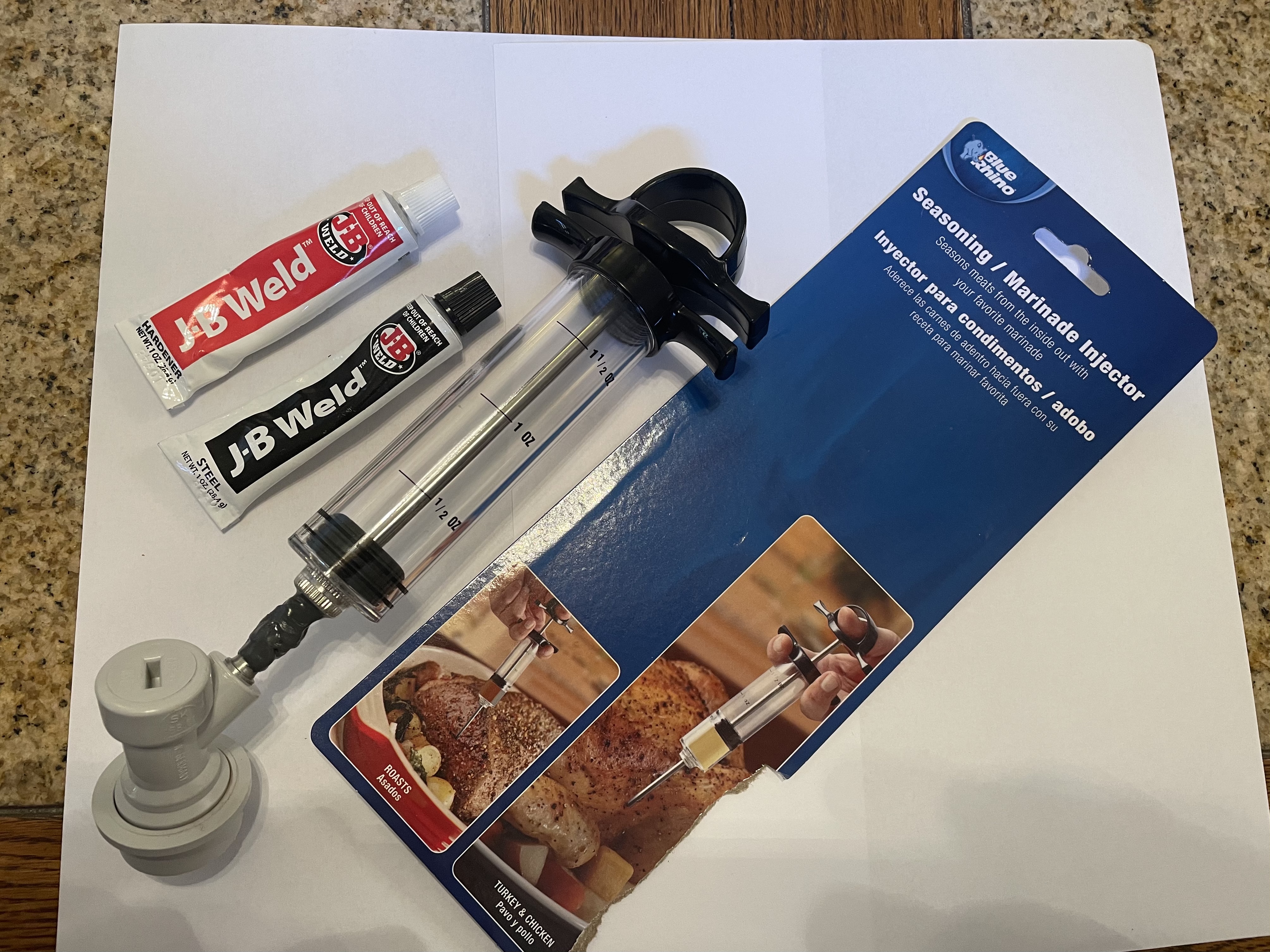

This is how I did it.

OG: 1.050

FG: Don't know yet, it'll be 1.009-ish

IBU: Not the foggiest

SRM: Fizzy and yellow

70% German Pils

20% Corn

10% Rice

90min: A token amount of magnum to keep the beer from being a Foppish Dandy.

20min: The most amount of Liberty hops you can squeeze in here.

10min: Your key hops charge, put a lot of Liberty hops here.

DIP HOP: 2oz of Liberty hops. Prior to flame out, run off about .25 of a gallon into a pasta pot. Let it sit for a few minutes while you discover that your perfectly prepared clean, yeast-free, fermenter is missing a stopper. Find it. At this point your wort in the pasta pot should be about 170F. Now dump your hops into the fermenter, followed by the wort you reserved from the kettle. Magic will happen, they say. Close your fermenter right away because the magic pixie dust only happens when you're not looking.

Finish the boil, then run off, as normal, into the fermenter.

I have no idea what it'll taste like in the glass, but I'm told it's amazing.

I've been told that before.

Bottled up an Irish Stout and a Belgian Tripel I brewed up a couple weeks ago. Both tasted good pre-carbing/bottle conditioning. Tried my first crack at a Blue Moon clone and it was a bit orange forward. It’s only been two weeks so I’m hoping it evens out with time.

How much orange did you use? Just asking because I'm getting ready to brew a blue moon clone as well.

I have one too with the floating dip tube! it's awesome especially for ipas. I got the spunding valve attachment too, and that thing is great!I kegged my altbier today. It was my first time using the floating dip tube filter for my Fermzilla. Damn impressed. I was able to drain pretty much all the beer off the trub and it ran clear the whole time. Previously I would either have to leave a lot more beer behind in the fermenter or would be sucking a decent amount of crap in towards the end.

I have two myself LOL. I use one in case I have a crazy hoppy beer in the keg and one for the fermzilla. I have the blow tie one from keg land with the PSI gauge attachment, and it was $35. I've had good results with it. I just set ot between 5 and 7 PSI so it carbs the beer up a little bit and keep aromatics in. Then, I set it on the co2 input of my keg when I do a closed transfer and set my psi to 10 on my regulator when transferring.I have two floating dip tubes. Good stuff. I spund in the keg as well.

@aharri1 what spunding valve attachment do you have? I've kinda given up on the attachment. Just prime the keg and use the blow off valve if it is too foamy.

I cleaned some kegs, filled a keg with a half batch of mild, and brewed 6 gallons of an oatmeal dry stout tonight. And started another half pint of vinegar from a cyser I need to apple jack and bottle.

Good to hear you're up and brewing. Hopefully, your poke kept the worst of covid at bay, and a little homebrew did the rest of the heavy lifting.Two more days till end of quarantine, so cleaned the heck out of the garage/brewery, with many rest breaks. Also just gave the husband his monthly haircut, I'm getting good at that. I'll more than likely be working both days this weekend, so I planned an easy brewday tomorrow with a lemon drop blonde. Need to build the pipeline back up.