K3 is fully up and chillin' down!

Today I calibrated all (9) temperature sensors together to a tenth of a degree F, installed the lid gasket, filled and tested the rinser, drain and vent, then connected the compressor to the control system and turned it on. After nothing happened for a couple of minutes - and a split moment before panic could show its head - I realized I had the freezer thermostat set to the "Off" position (dumb ass

)

So...I used a 3/8" thick inch-wide "dual D" closed cell foam weatherstrip recommended by a fellow HBT member - and didn't split the twin "D" strips, just applied them together for a double-course of stripping.

Went with 45° cuts at the ends and jammed the ends together. Hopefully they squish together tight where I can't see 'em.

With the gasket in place I set the lid down, then loosened the hinge screws and went around the lid with an inside caliper to get the gap set to a uniform 3/16" before tightening the hinge screws down.

Down in the luxuriously spacious bidness area I have two EVA Dry E-500s (with 40mm fans driving cabinet air into them for

much better performance), a 120mm fan on the hump blowing lengthwise down the aisle, and a small plastic container with the "Lower Cabinet" temperature sensor tie-wrapped to it sitting on the floor.

The shorty kegs on the hump are the rinser water supply (2.5g) and the rinser tray drainage catcher (3g). Getting these both on the hump saves floor space for actual beer kegs

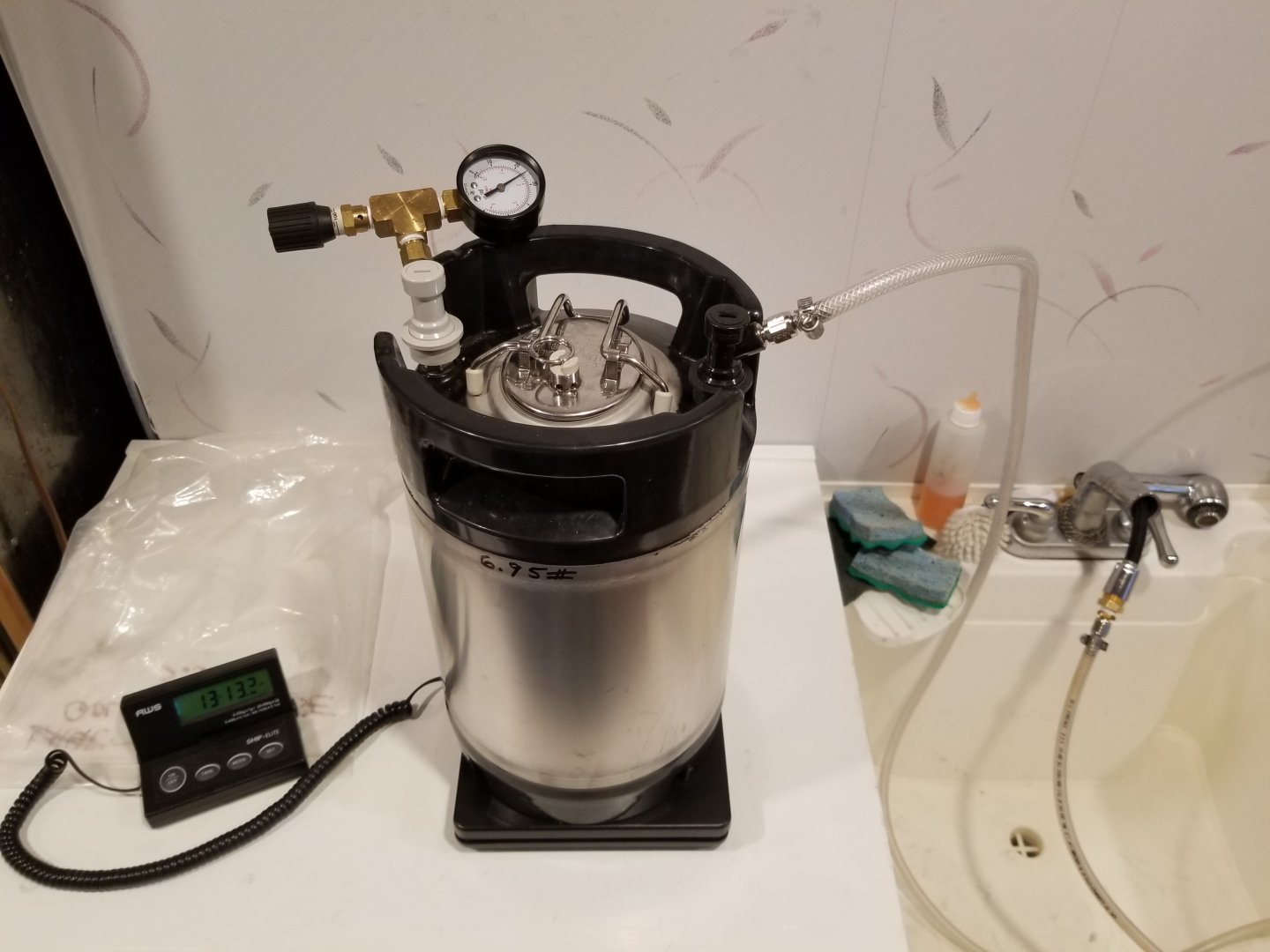

Filling the 2.5g rinser water keg with 2 gallons of fresh water. I use a scale tared with everything attached then fill to ~16.5 pounds, while using my spunding gauge to keep the head space pressure below 60 psi. This keg feeds an adjustable regulator (seen at the top of the previous pic) to drop the pressure at the rinser valve to 15 psi as recommended by the manufacturer. The "catch keg" is vented outside the cabinet through another bulkhead.

Rinser in action...

So, now I wait for the beast to get down to 36°F, at which point I can stick a few kegs of beer in it.

Then I'm gonna be brewing like a maniac to get my pipeline going again - I have 12 empty kegs, a turrible situation!

Cheers!

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)