Today...mostly due to stupid luck, I saved a keg of imperial chocolate stout from disaster.

During the week my normal "first pour" typically happens at the stroke of 5pm by intent. But today I was cleaning up after priming the east end of the house, and didn't get to the brewery until 5:13 - when I discovered the stout bubbling up through the

handle end of my Micromatic stout faucet! WTH! And

YIKES!

Immediately called The Spousal Unit down for emergency assistance as I observed my stout was slowly disappearing down through the drip tray drain into the 3 gallon catch keg inside the keezer. Good it wasn't all over the place - bad that I had no idea how much stout had already been lost.

First instinct was to pull the handle and let it snap back hoping it would seal up tight. A r

eally bad move - instantly the leak rate easily tripled, now flowing at around a quarter-ounce per second. I had the wife hold a 1/2 gallon plastic bucket under the faucet while I used a shop towel to soak up enough of the stout still in the tray to lift the keezer lid just enough to reach in and pop the beer QD off the stout keg.

Flow then stopped, we mopped up the keezer top so I could open the lid fully. I pulled the catch keg and discovered there was barely a cup of stout therein!

The wife had caught another cup and I mopped up nearly as much, so it looks like the loss was under a quart. An hour more cleaning, pulling the drain tubing off my drip tray and rinser and cleaning them bright again, draining and cleaning the catch keg, updating my tap list to account for the lost stout, and we were back in bidness.

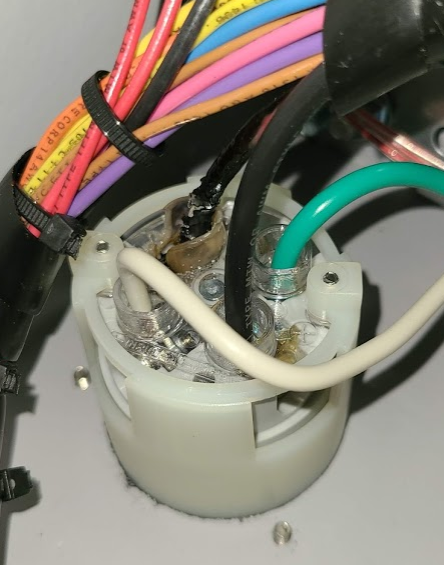

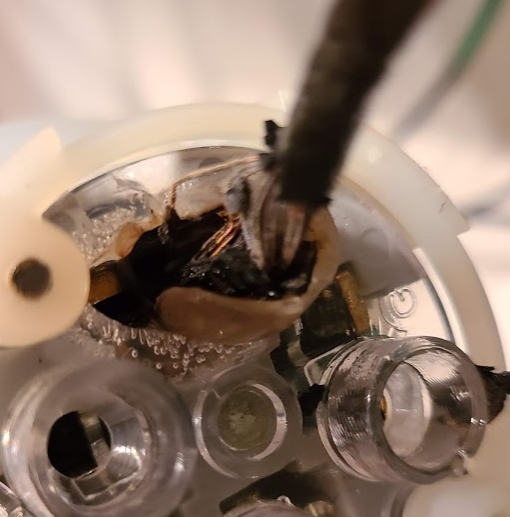

I pulled the Micromatic faucet and took it apart. This diaphragm is the culprit...

View attachment 685324

Right at the seam between the bottom tapered section and the immediately adjacent reversed taper above there's a breach. Clearly fatigue failure.

It's a $5 part direct from Micromatic (and I bought two) but it'll likely take most of a week to get here. I stuck my 6th 525ss Perl in its place for the time being but will probably have to drop the nitro pressure waaaaay down to get a tame pour out of it

Could have been so much worse though - like, if it had happened at any other time of the day. That keg had over 4 gallons in it last night, my catch keg is only 3 gallons, and once that is full and the drip tray overflows there would be an epic mess...not to mention a tragic loss of my nitecap for a month. That would be "double-plus ungood!"

I'm now trying to remember how many years I've been running this faucet so I can hopefully PM that diaphragm well before it fails. Kinda like the timing belt on an interference engine, if it fails it's catastrophic. Pretty sure it's at least 8 or 9 years old...

Cheers!

), did a final grav on the honey Irish Red 7.6%!

), did a final grav on the honey Irish Red 7.6%!  . Thought today was the big day of 1st kegging but guess it will have to be tomorrow.

. Thought today was the big day of 1st kegging but guess it will have to be tomorrow.

The wife had caught another cup and I mopped up nearly as much, so it looks like the loss was under a quart. An hour more cleaning, pulling the drain tubing off my drip tray and rinser and cleaning them bright again, draining and cleaning the catch keg, updating my tap list to account for the lost stout, and we were back in bidness.

The wife had caught another cup and I mopped up nearly as much, so it looks like the loss was under a quart. An hour more cleaning, pulling the drain tubing off my drip tray and rinser and cleaning them bright again, draining and cleaning the catch keg, updating my tap list to account for the lost stout, and we were back in bidness.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)