You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What I did for beer today

- Thread starter iaefebs

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

I have no idea as I don't have a o2 meter. I just read that most low o2 folks use this method. Previously I used camden tablets as part of my process, which some say reduce oxygen.What was the O2 concentration before and after?

ClaudiusB

Well-Known Member

Thanks for replyingI have no idea as I don't have a o2 meter. I just read that most low o2 folks use this method. Previously I used camden tablets as part of my process, which some say reduce oxygen.

Checked on the pilsner - day 2.5... still bubbling nicely, but no longer at speed metal tempos... Currently about 140 bpm. Should finish up the fast bubble era in a day or two.

Readjusted carb levels - turned up the English bitter because I am impatient, and turned down the pale ale as it is now fully carbed and could settle down a little.

Day 3 for my next stout in the keezer. My last stout batch feels like it has maybe 3-6 pours left, so I put in the replacement keg of stout on Tuesday and began to carb/nitro mix ... So it is ready on day one when I need it ready.

Readjusted carb levels - turned up the English bitter because I am impatient, and turned down the pale ale as it is now fully carbed and could settle down a little.

Day 3 for my next stout in the keezer. My last stout batch feels like it has maybe 3-6 pours left, so I put in the replacement keg of stout on Tuesday and began to carb/nitro mix ... So it is ready on day one when I need it ready.

Last edited:

Halfakneecap

Well-Known Member

Kegged and naturally primed a dark ale with 1968, haven't used it in a long time, man is it a great yeast. Not really a porter. Cant wait to drink it. Might get the nitro bottle out, if its not empty.

Also, pitched yeast into my witbier.

Also, pitched yeast into my witbier.

- Joined

- Sep 6, 2021

- Messages

- 583

- Reaction score

- 2,515

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$28.98

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Great Fermentations of Indiana

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$159.99 ($26.66 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

SpaceCityProviders

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

@T Murph I have that duo tight setup and love it. I would suggest getting 6 shut off valves and 6 check valves (back flow) ... Both are helpful in ongoing management of CO2 pressure and changing out kegs. Also ... The regulator gauges of 0-15 is much better than the 0-60 for precision and ease of use for older folks like me.Last week I recieved my 6 regulator board and all the hardware. Today I finally got it installed and everything hooked up. Time will tell how well it works. But it has to be better than switching a single Co2 line from keg to keg.

As for the Saaz and mittelfru combo ... Did a batch (day 4 of fermenting) and looking forward to it. Thanks for the suggestion.

- Joined

- Sep 6, 2021

- Messages

- 583

- Reaction score

- 2,515

When I made the switch over to the Brew Buckets I looked at those spigot and racking arm gaskets and I determined that they were flashing, neon-lighted failure points, so I put together a crash box for those gaskets. You can see it pictured below. To my surprise, they've been quite durable. I've occasionally swapped them out for reasons of caution, but I have yet to have one actually fail. (way to jinx yourself, BC)

Good, cheap insurance there. You can never have too many o-rings on hand.

When I first bought a Brew Bucket, that was one of the "weak link" things I spotted. The racking arm o-rings stretch easily and the next time I'd try to insert the arm into the valve, the rings would deform, pop out of the grooves and stick out.

There was a post on HBT where they suggested better replacement rings, from The Oring Store. So I ordered a bunch of them. Buna rubber. I can now replace the rings every 2nd brew or so.

As for the "rotating racking arm," I never use that. I position the racking tube pointing up all along, trub be damned. The prospect of twisting a valve with a batch of beer behind it gives me more than a little pause. If you intend to rotate it clockwise at racking time that means keeping the valve slightly loose during fermentation so it can rotate 1/4 turn later. Going the other direction is a non-starter. You want 5 gallons of beer on the floor? Because that's how you get 5 gallons of beer on the floor.

If I get a little trub in the racking tube it blasts out the minute I open the valve. I catch that in a cup, and I only lose an ounce or so. Then I go about racking.

If the trub doesn't blast out (only happened to me once), a gentle push with CO2 at 1 or 2 psi will get things flowing.

Dry hopped my low ABV Saison, which has finally stopped fermenting after about three weeks. 70g (about 2.5oz) each of BRU-1 Cryo and T45 Nelson Sauvin. Smells good.

Today I brewed 15 litres of dry stout

2400g Vienna malt

300g Rolled oats

150g Chocolate malt

150g Roat Barley

100g Medium Crystal 240 L

150g Brown sugar and Dextrose.

Bramling cross 30g at 45m 20g at 15m

CML Five yeast.

I also bottled my Niagara Wheat beer into 22 half litre bottles.

2400g Vienna malt

300g Rolled oats

150g Chocolate malt

150g Roat Barley

100g Medium Crystal 240 L

150g Brown sugar and Dextrose.

Bramling cross 30g at 45m 20g at 15m

CML Five yeast.

I also bottled my Niagara Wheat beer into 22 half litre bottles.

Did a HB stout keg transfer perfectly. Hurray. What is perfect?

1) Knowing the old stout corny is gonna kick in the next 10 days.

2) pulling the on deck stout out of closet storage and cold crashing over 4-5 days

3) putting the chilled on deck keg and carbing it with beer gas once or twice a day for at least 5 days.

4) old stout keg kicked. Switch beer line and beer gas to the "ready" stout and pour off a few inches in case you have some trub left in the lines.

5) pour the new stout keg. It's cold. Has a solid head. Awesome bubbles with no waiting.

I love stout and being without HB stout tap #6 ... Will not stand. Ha.

1) Knowing the old stout corny is gonna kick in the next 10 days.

2) pulling the on deck stout out of closet storage and cold crashing over 4-5 days

3) putting the chilled on deck keg and carbing it with beer gas once or twice a day for at least 5 days.

4) old stout keg kicked. Switch beer line and beer gas to the "ready" stout and pour off a few inches in case you have some trub left in the lines.

5) pour the new stout keg. It's cold. Has a solid head. Awesome bubbles with no waiting.

I love stout and being without HB stout tap #6 ... Will not stand. Ha.

The lid gaskets for my Brewtech Brew Buckets arrived yesterday and I swapped out the gasket on my ale fermenter. I was surprised at the deformation in the old gasket when compared to the new one. Silicone is tough stuff, so this really surprised me. Anyway, I'm glad I did it.

Brewed 23L (fermenter volume) of west coast table pale. Under 4%, hopped with Amarillo, Centennial and Luminosa.

I had a really light day scheduled yesterday, so I set myself up to do some early afternoon brewing. I haven't brewed in the afternoon in forever, it was really weird--"Ugh! It's 4.30 and I still have 20 minutes to go on the boil! What's going on?!!!!"

The odd bit of confusion aside, it was a pleasant enough brew day and I now have 6.5 gallons of ordinary bitter passing through 1.025 as I write this. No complaints.

The odd bit of confusion aside, it was a pleasant enough brew day and I now have 6.5 gallons of ordinary bitter passing through 1.025 as I write this. No complaints.

I spread about 1.5 yards of mulch for beer today. Tomorrow I finish the mulch and start the dirt pile.

Bottled 2-5 gallon batches (48 bottles/ea) "Hungry Brown Dog" American Brown ale; and Kujo's Cave Porter @ 7.9 % abv. Don't anticipate getting after the Porter until the leaves turn. Looking forward to the HBD in a couple of weeks. Have 2 pale/hoppy ales planned for later this week to round out my summer

brewing.

brewing.

1) upped the temp in the inkbird "ferm chamber" for the German Pilsner ... Day 2 of D rest. Now at 63°F after 13 days at 55°F.

2) Weighed grains for an 11 gal batch of Mocha Irish Stout. Made a change to the recipe, using a blend of breiss dark chocolate and chocolate malt (450L vs 350L). Probably will brew tomorrow but can wait - nothing milled yet.

3) swapped out a kicked keg (pale ale) for an already chilled and carbed blonde ale. Going to move another corny to the "on deck circle" in the keezer.

4) more work tweaking out the man cave where the beers disappear. Fixed a crappy old ceiling fan to looking mint. Just Elbow grease followed by paint.

Busy day. Time for a cold one.

2) Weighed grains for an 11 gal batch of Mocha Irish Stout. Made a change to the recipe, using a blend of breiss dark chocolate and chocolate malt (450L vs 350L). Probably will brew tomorrow but can wait - nothing milled yet.

3) swapped out a kicked keg (pale ale) for an already chilled and carbed blonde ale. Going to move another corny to the "on deck circle" in the keezer.

4) more work tweaking out the man cave where the beers disappear. Fixed a crappy old ceiling fan to looking mint. Just Elbow grease followed by paint.

Busy day. Time for a cold one.

Kegged my latest batch of chocolate stout, which ended up at 12.2% ABV...

Cheers!

Cheers!

@day_trippr I keep meaning to make that recipe you generously shared! Only ingredient I don't have easy access to is "Caramalt". Would briess caramel 10L or 20L be a good substitute? Turns out he already answered that in the very thread I linked ("yes, those are good substitutions for caramalt")

Last edited:

One more day left on the German Pilsner before a slow cold crash, and lager. Checked for the FG which came in at 1.002. yeah, it's gonna be dry as a bone. The sample was magnificent and I know this won't last long in the summer heat once carbed and tapped.

Also brewed 11 gal of stout this morning. In the fermenters and ready to do the bubble dance tonight, tomorrow, etc ..

Also brewed 11 gal of stout this morning. In the fermenters and ready to do the bubble dance tonight, tomorrow, etc ..

Attachments

5 gallons of Hops Kitchen IPA into fv @ 1.069 this afternoon. Brewing again tomorrow. Will add images next post.

Monday I bottled my Dry Stout 23 half litre bottles at 4.6%.

Encouraged by the results of last week's late afternoon brew session, I'm doing it again. I'm doing the Ron Patinson 1971 Boddington's recipe. I hate pinching other people's recipes, but it's a good one.

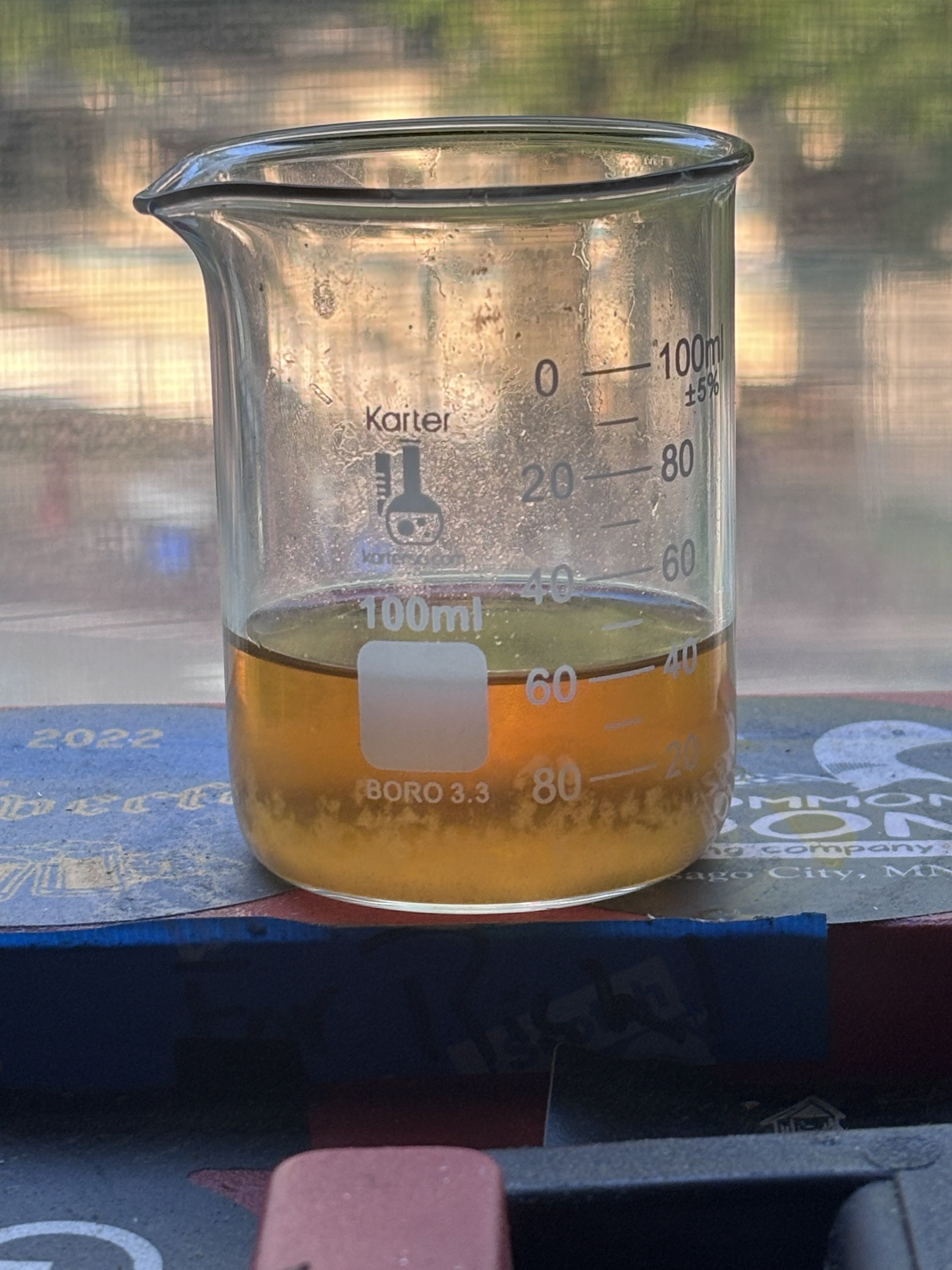

My wee tiny little mash.

My wee tiny little mash.

Encouraged by the results of last week's late afternoon brew session, I'm doing it again. I'm doing the Ron Patinson 1971 Boddington's recipe. I hate pinching other people's recipes, but it's a good one.

My wee tiny little mash.

View attachment 878013

Can't argue with success. I'm not above pinching a good recipe. Sometimes I MacGyver it and change one small thing.

Now if I could just close in on a Fuller's London Porter...

https://www.homebrewtalk.com/thread...ipa-from-the-horses-mouth.642756/post-8674860.

Now if I could just close in on a Fuller's London Porter...

I brewed the 5.4% recipe in the link, I don't know how it compares to the real thing but it tasted good to me.

edit: I have a pouch PUB that is bulging and needs to be used, torn between brewing the porter again or a best bitter first.

I was surprised when I saw this recipe for Fuller's 1897 Porter. It's basically the UK porter that I had iterated into over the years. The only difference is that I use only a pound of invert #3 and more base malt with a slightly lower OG. I guess it's not all that surprising, it's not a complex recipe and the basic ingredients are well-established. It makes a nice porter, although I've never used 26% invert. That seems like a bit much to me.Can't argue with success. I'm not above pinching a good recipe. Sometimes I MacGyver it and change one small thing.

Now if I could just close in on a Fuller's London Porter...

With that said, I think Fuller's is much more modest with their use of invert sugar in their contemporary brewery. They may not even use it at all. Not sure where I remember that from, but it's certainly lodged in the back of my noggin. I've found that one pound at 1.054 gets the job done. It provides the flavors you want without thinning the ale too much.

Chilling wort and my artsy hop additions ready for the boil.

Cleaned out the SS brew bucket that had the German Pilsner and packaged that in a clean and gas checked corny. Oh my... Absolutely gorgeous beer - clear and clean. 34/70 doing the job well at a steady 55°F fermentation. Carbing up now in the keezer "on deck circle".

Also cleaned out 2 corny kegs. The blue top corny was from the kicked Mocha Stout and sat for a week before cleaning... And had a wild smell like acetone. (Ethyl acetate?) Hmmm. Research. Learn something every day. My best guess is I had some "autolysis" - which basically means the enzymes and cells are eating themselves in a death throw. Cleaned it out well with PBW and very hot water, letting it soak for an hour with a lot of shaking and swishing.

No smell at all after cleaning . Note to self... When a corny kicks, at least give it a good rinse if you feel like waiting to clean it.

Also cleaned out 2 corny kegs. The blue top corny was from the kicked Mocha Stout and sat for a week before cleaning... And had a wild smell like acetone. (Ethyl acetate?) Hmmm. Research. Learn something every day. My best guess is I had some "autolysis" - which basically means the enzymes and cells are eating themselves in a death throw. Cleaned it out well with PBW and very hot water, letting it soak for an hour with a lot of shaking and swishing.

No smell at all after cleaning . Note to self... When a corny kicks, at least give it a good rinse if you feel like waiting to clean it.

Attachments

Last edited:

My back is envious of your keezer filling apparatus .It was time to refill the keezer.

View attachment 878165

This morning cranked up the temperature on the latest version of novalager-fermented blonde thing in the pressure fermenter. Brewed it on Thursday since I was home for the day, it took off galloping and stayed at 68° despite my forgetting to turn on the heat lamp. Will let it warm up and stay there for a day or two before crashing. First one is going fast since I stupidly told the husband which tap it was on. Dunno why I gave up on Novalager yeast in favor of 34/70, it's a beast and ferments clean, although not very clear; but who cares? That's what gelatin is for.

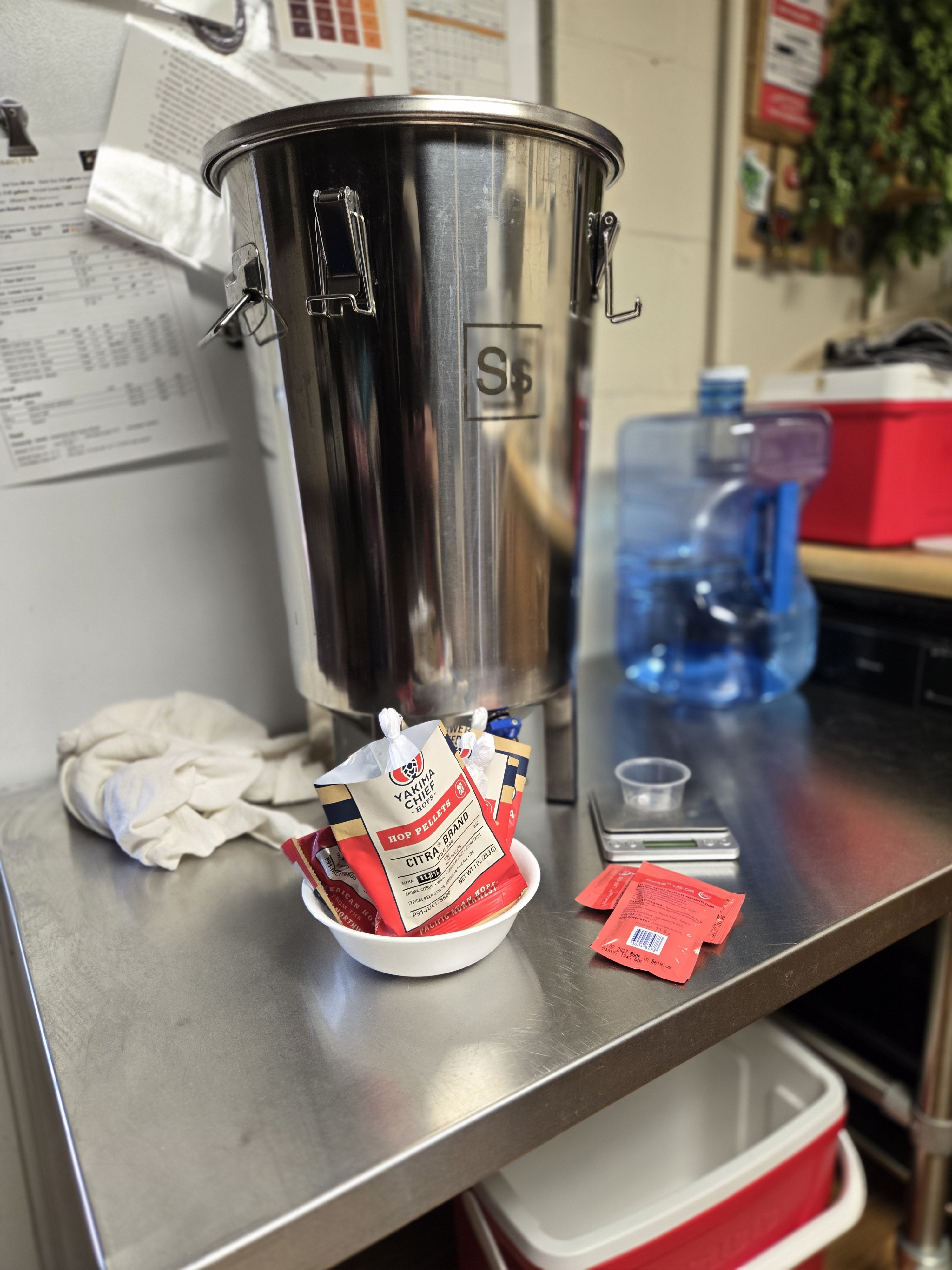

My first LODO brew... 6 grams yeast and 6 grams sugar into the strike water (3.8 gallons)... For a hoppy (lotsa citra dryhop) pale ale that I've made a couple of times, hoping this 4th attempt has the aroma last longer. Planning to minimize oxygen in every step.

Kegged up my table pale with Amarillo, Centennial and Luminosa. Had the same weird behaviour with the Luminosa DH that I always get with Strata in that the super powdery, sticky hop matter ends up floating on the top rather than ever dropping out. Nothing the filter didn't sort out. Maybe it's an Indie Hop thing? Their pellets are much powderier than BarthHaas or Yakima ones.

Aim with this was to brew a 3.5% pale that doesn't taste like a 3.5% beer and from the warm transfer sample it looks like I nailed that.

Aim with this was to brew a 3.5% pale that doesn't taste like a 3.5% beer and from the warm transfer sample it looks like I nailed that.

- Joined

- Sep 6, 2021

- Messages

- 583

- Reaction score

- 2,515

Bottled kitchen sink Amber? Lager? Numbers are right, gravity sample tasted pretty good.

Today I bottled Sandstone Trail (a walk along the Sandstone Ridge in Cheshire). 31 half litres bottles of an English IPA with EKG, Bramling Cross and Harlequin hops. ABV 5.9%.

- Joined

- Sep 6, 2021

- Messages

- 583

- Reaction score

- 2,515

Looking for someone who's brewed with Kernza grain. Just finished a dogfish greatful dead July made with Kernza. Very good

Similar threads

- Replies

- 66

- Views

- 2K

- Replies

- 20

- Views

- 1K

- Replies

- 55

- Views

- 2K

Latest posts

-

-

-

-

-

-

-

For Sale SS Brewtech - 7 Gallon Unitank 1.0

- Latest: IslandLizard

-

![20250605_155107[1].jpg](https://cdn.homebrewtalk.com/data/attachments/817/817907-c2c9edbebb6cbc3a869418bc0d032115.jpg)

![20250605_155220[1].jpg](https://cdn.homebrewtalk.com/data/attachments/817/817908-7a8286bd08d58470d9da92776bffc089.jpg)

![20250605_135637[1].jpg](https://cdn.homebrewtalk.com/data/attachments/817/817909-22a7392c2885b5cb898cc56c8ee7e7a0.jpg)

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)