I started brewing version 40 off of CSI's website on 29th May. It's currently sitting in tertiary. I thought people might be interested in a graph of the fermentation. I have a fridge I have converted to use the BrewPi control system with a small space heater inside and various sensors. I also have a tilt hydrometer which the BrewPi logs.

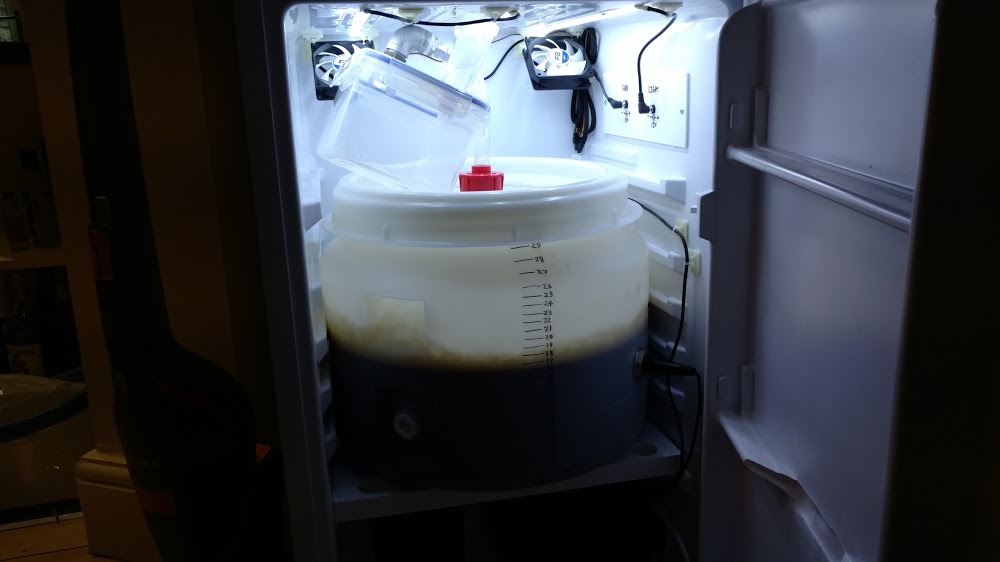

This photo shows the inside of the fridge with a previous brew in it.

This shows the Westvleteren 12 with my DIY kreusen capture which wasn't needed in the end.

The capture device is just a lunch box with a hole for an air-lock and a hole for hose barb. To prevent anything bursting open and getting goo everywhere, I used a fermentor with a full width lid (easy to clean) that is held down by a large threaded ring (no chance of it popping off). That red thing in the middle is a screw on cap. The fermentor came with a blank one and one with a hole that snugly fits 1/2" hose. To stop the hose popping out, I used a male quick-disconnect - barb inserted into the hose on the inside. This is really easy to sanitise and once inserted expends the hose so it can't be pushed out of the hole.

Another neat thing about this setup is the port on the bottom left of the fermentor in the first pic. It came with a blanking piece (which I've used) and a spigot. But that's not what's interesting. Where it attaches is slightly in-set from the rest of the fermentor with a slope at the bottom. The plastic is translucent enough that you can see the bubbles from the yeast at the bottom hitting and moving up this slope. When the fermentation slowed, the bubbles almost stopped in the air lock and the hydrometer practically stopped moving. But the little bubbles were still clearly visible here!

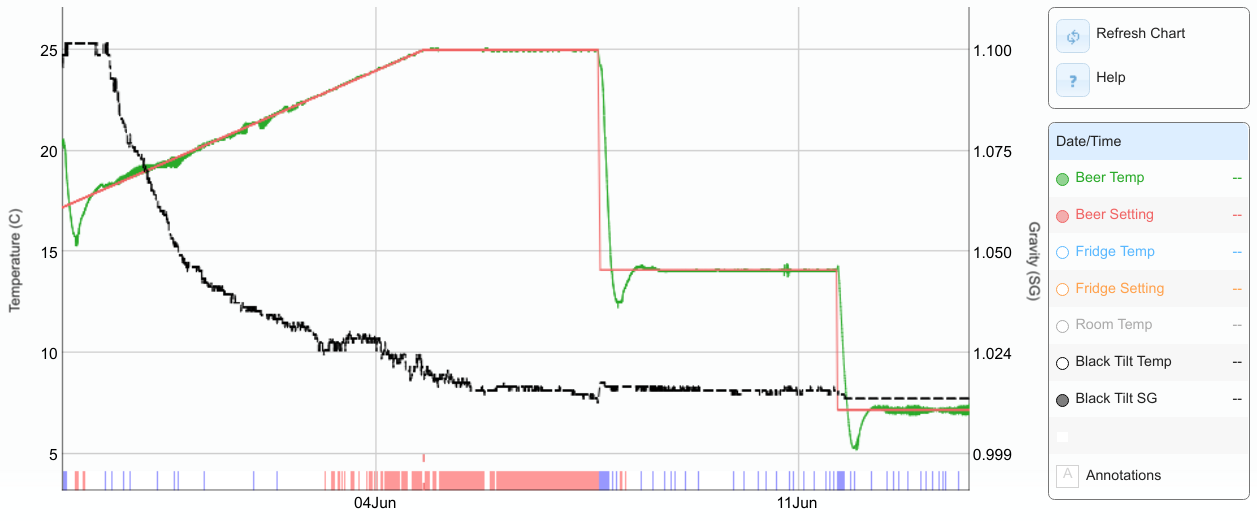

Finally, my graph.

The hydrometer isn't 100% accurate, particularly at the top. I forgot to calibrate it with my actual OG reading which was far higher than the wort from my calibration run for the hydrometer. This hydrometer is best used to gauge activity and approx gravity along with a glass hydrometer for accurate readings. OG was 1.090 and the SG going in to secondary was 1.012/1.013 as measured with an old-school glass hydrometer. Note that the gravity went up after transfer to secondary. I think this is because I cleaned quite a bit of krausen off of the hydrometer when transferring. The gravity dropped slightly in secondary, looking at the graph, so I think the FG is around 1.011/1.012. I haven't taken another reading because its about right and what doesn't go in my trial jar goes in the bottles!

Interesting observations with this beer. The last few points took several days. I think with if I'd just been using my glass hydrometer, I might have worried I'd stopped a few points short and given up a day or so earlier and racked to secondary. I also found the temperature of the beer extremely erratic during fermentation. The lively nature of the yeast meant readings bounced +/- 1degC on my real-time readout of the digital thermometer. Far more than usual. You might also notice the temp took a little while to settle down as I was off by a few degrees when it went in the fridge. I'm not too worried by that as it'd be in the lag phase where the yeast is mainly metabolising aerobically and giving off fewer flavour compounds. The temp had settled by the time it started eating through the sugars.

So hows the beer doing? The samples tasted amazing! I was lucky enough to drive over from the UK to St Sixtus with my wife for our honeymoon at the beginning of April and pick up a couple of crates. The young Westvleteren 12 when you pick it up has quite a few hot flavours that overpower the fruits/spices flavours. These begin ageing out relatively quickly though and were notably lower in the second bottle which we opened while brewing this clone. Having had a bottle about 1year old in the past which was much cleaner and complex, I'm the reason some people review the beer and say it is over-rated is because they drank it too young. The sample from ours going into secondary had far fewer of those hot flavours. I'm really interested to see how ours turns out as right now it tastes better than the real thing when drunk too young! We're opening our real Westvleteren 12's about one every 2 months to see how it ages. So it'll be very interesting to see how this clone compares.

Once this brew is in the bottle and our temp controlled fridge is free again, we are planning to brew Saq's recipe listed in the fantastic round-up of the previous thread that can be found on page 3 of this thread. For those who haven't read all the way through this and the previous thread, Saq helped develop the original clone several years ago. He developed it over the years along with others on these forums. Early on CSI set up his company producing Candi Syrup that is reportedly far better than anything available before. Him and his company partners used this clone as one of their tests for their products. Eventually, CSI took the lead on these threads and continued to develop the recipe and keeping it up to date on his company's website. In around 2014, they noticed a clear change from a more complex malt bill to the all-pale malt bill in the recipes today. The updated version of Saq's recipe in the round-up on page 3 of this thread is probably the closest thing to the pre-2014 recipe which some people preferred. We're brewing that immediately after this to compare.

I'll try and remember to post again when we brew Saq's recipe and when they have both aged in the bottle a bit.

Thank you to all who have contributed, btw. I started building our first all-grain brew setup and the fridge around Xmas. They were designed specifically to be able to brew this beer. This recipe was the inspiration for many of the features of both and we probably wouldn't be in this position of enjoying ourselves so much with this hobby without that goal to aim for.

Cheers

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)