Love my two-tier

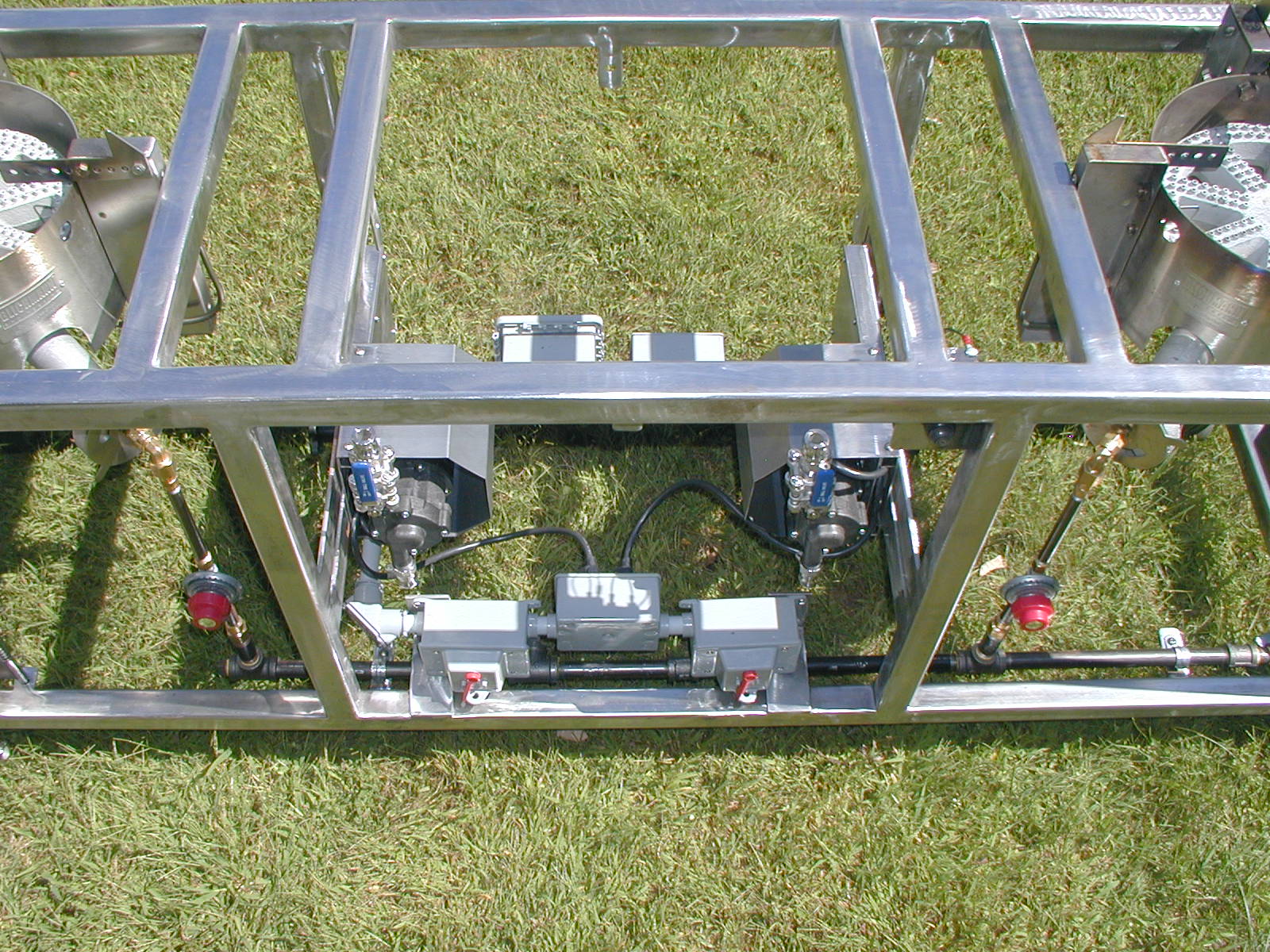

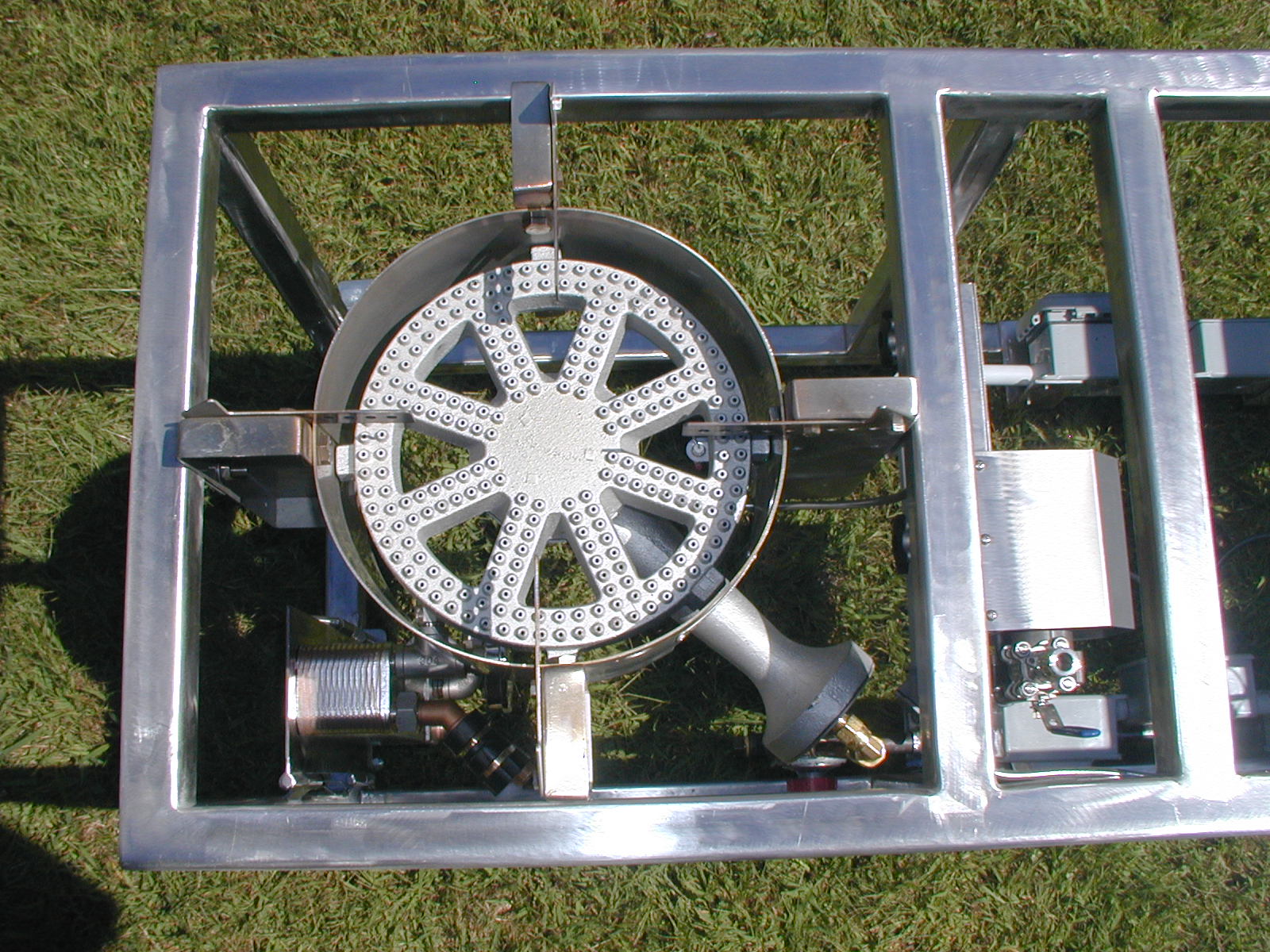

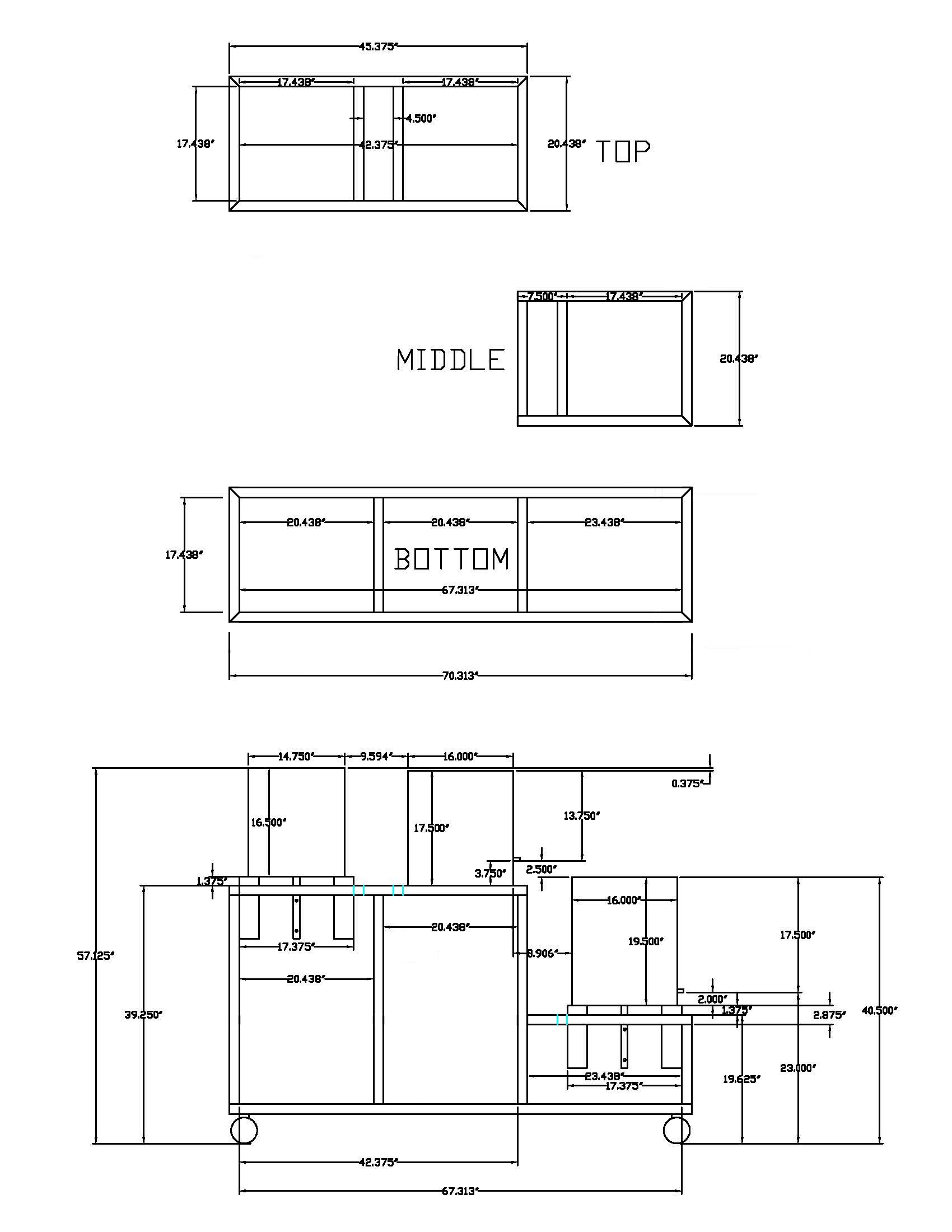

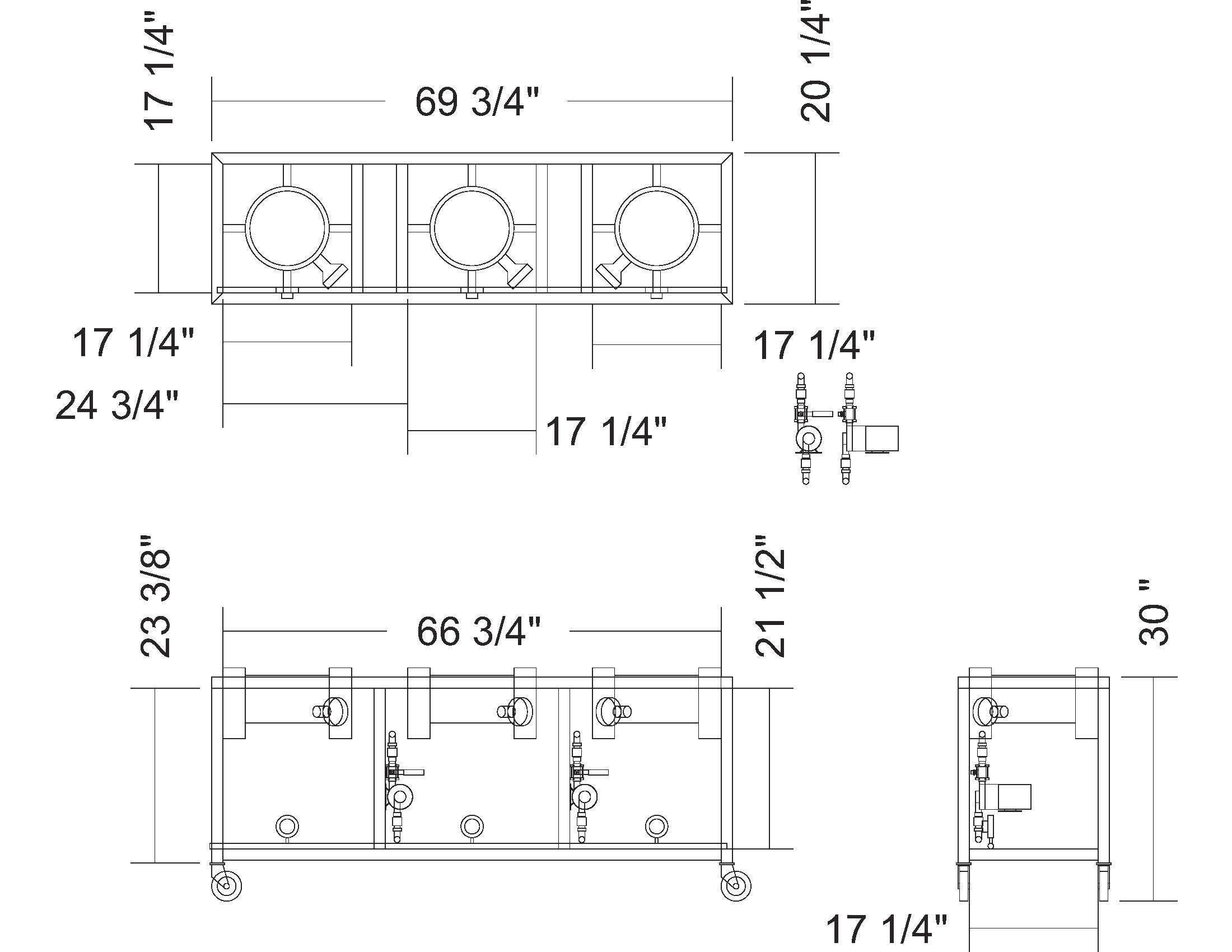

1.5" square tube .060" wall. .030 wire with argon/co2 shielding gas. $75 to powdercoat. Solid as a rock. My 3rd build. Dimensions plagiarized a little from the old Sabco systems.

Fully electric HERMS system but I put adjustable height burners on it thinking I could use them someday (speed things up, rotating batches, take it to a friends place without 220V power, whatever). Has about 30 batches on it and i've never even lit the burners to see if they work. Have no clue where my heat/flame shields went. Hmmm.

Side note on two-tier... There are still reasons you *might* need a 2nd pump. (1) whirlpooling. I just use a giant spoon, works fine. (2) chilling, if not using a immersion style. (3) your fermenter is too tall to drain into.

I have conicals on stands so draining into the fermenter is out of the question. I built a counterflow chiller with a pump on a separate little wheely cart. Solved (2) and (3) at the same time. I might incorporate the 2nd pump and chiller into frame on the next revision

View attachment 614859

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)