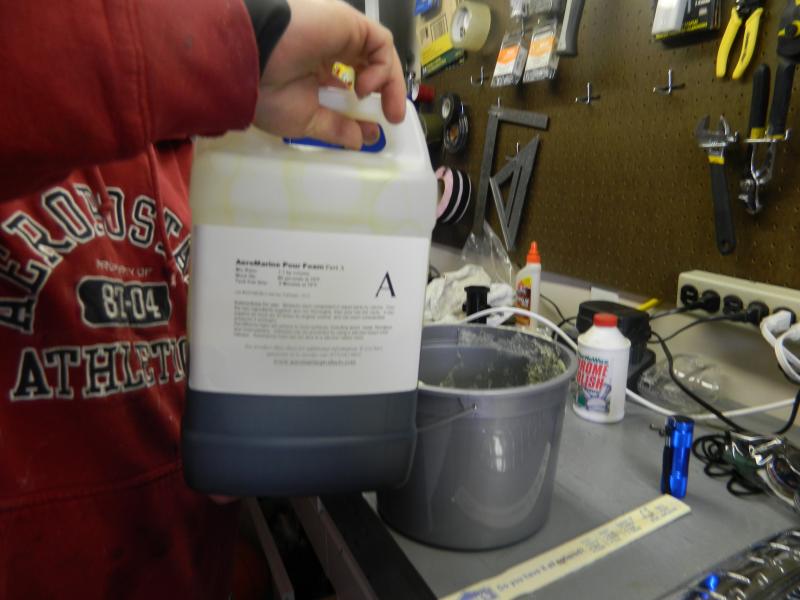

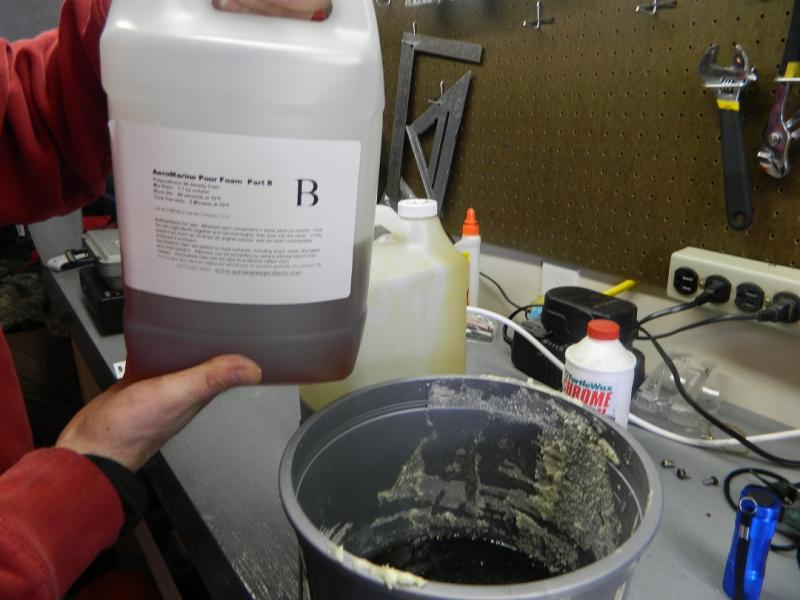

Just got off the phone with a tech at AeroMarine and found out that the reason the first attempt of foam insulation did not expand as much as it should have was due to the outside temperature. The day I did this, it was about 60 degrees outside and the bottles of polyurethane foam had been sitting in the garage at very low temps. Before I used them, I should have let them get up to atleast 70 degrees. This specific product expands to its fullest at 75 degrees.

I also found out that I am not the only person that has and or will be using this product in a freezer. The temperature ranges of a freezer are well within the limits that the polyurethane can handle. And working with such an old appliance, my other concern was how combustable it might be. When held to an open flame, the foam will simply just char and break down. So that eases the mind for fear of a possible electrical fire.

The 2# polyurethane foam yeilded an R-rating of 7, and the tech was unsure of the thickness of the foam when tested. She also went on to say that the 2# is more than enough for a freezer.