For the record, yes - when connecting flow meters to 5V-compatible devices, like an Uno or Mega...

Cheers!

Cheers!

I want to install a RFID and flow values to keep track of usage and put a control over highschoolers. Would these instructions be the way to connect the RFID Card reader?

yes (I have to disagree with garzlok, the logic for RFID is in the PI not the UNO) I think those are the ones I followed, you dont need to do the commands as the setup did those for you. The example script may be helpful to make sure it is hooked up correctly.Would these instructions be the way to connect the RFID Card reader?

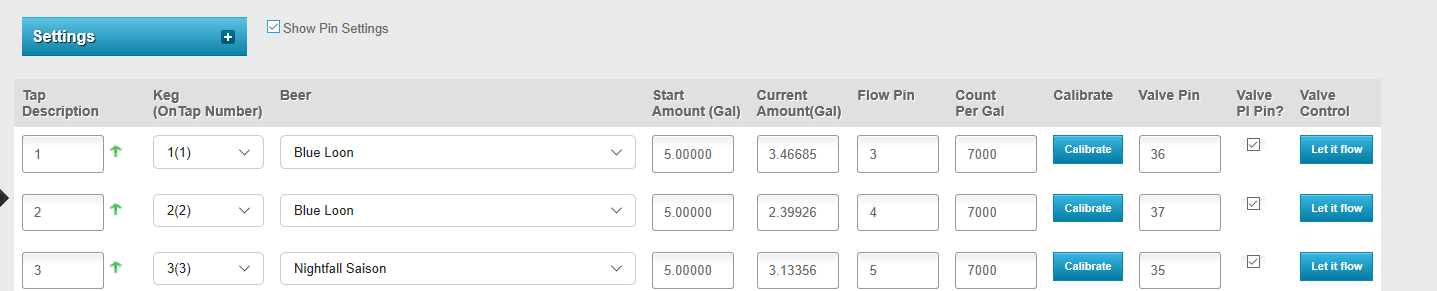

I use the Pi's higher numbered pins for the values signal (because alamode takes up the lower number), but you should be able to use the Shields pins also. Just make sure to check or uncheck Value Pi Pin depending on what you usewhere do I get the signal from to open the valves.

yes (I have to disagree with garzlok, the logic for RFID is in the PI not the UNO)

I guess I read a post that wasn't there....Whatever do you mean?

I use the Pi's higher numbered pins for the values signal (because alamode takes up the lower number)

Yes the RFID opens the valves. There is also a button on the taps screen to trigger the valves to open, but then will stay open until you hit the button again. The RFID will timeout and close the valves if no pour is detected. Also this only works if you have normally closed valves otherwise the trigger will close them...what triggers the valves to open. Is that the tagging of a rfid card or logging in of a user ? if so if there is no user logged into bpints are the valves are closed?

I have each tap on its own valve that way if someone is pouring on tap 1 a new RFID scan is needed to allow pouring on tap 2 (for example). you could have all the taps on one pin if you wanted but that means they all are open while a pour is happening but they all will shut when that pour is stoppeddifferent pins for different taps.

have each tap on its own valve that way if someone is pouring on tap 1 a new RFID scan is needed t

it opens all of them then when a pour is started it closes the ones not pouringknow what valve to open After I tag a card

it opens all of them then when a pour is started it closes the ones not pouring

off the back, no it seems like you enabled debugging so it should give you the error after 1Wire Temperature:but I don’t see any more details in the log. It works fine for 5 to 10 min then bombs until I restart flow monitor, Any suggestions ?

| 1Wire Temperature: list index out of range | 1 | |

| 2021-01-10 21:25:39 | FlowMonitor | I |

Can you tell me what files you have in the /sys/bus/w1/devices/28*/w1_slave directories (28* indicates directories that start with 28)?Ok here is the error log message I get. i haven’t put my system in the keezer yet so the temps are in the 75 degree range. Would that cause an out of range scenario?

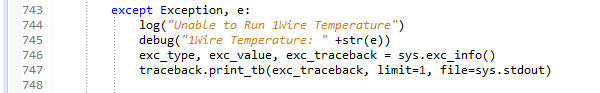

he other thing that will help me is if you add the following lines to 746 of FlowMonitor.py

exc_type, exc_value, exc_traceback = sys.exc_info()

traceback.print_tb(exc_traceback, limit=1, file=sys.stdout)

Can you tell me what files you have in the /sys/bus/w1/devices/28*/w1_slave directories (28* indicates directories that start with 28)?

Looks like the same code that I tested with but I don't see the stack trace printed out... wondering if its not outputting to the file like I did for meHere is the code I am running

Looks like the system detected 1 temp probe 3c01d075b9ec/sys/bus/w1/devices/28-3c01d075b9ec

Can you post the file?

/sys/bus/w1/devices/28-3c01d075b9ec/w1_slave

Thanks, I setup my test system with that info, but it didn't break....$ cat w1_slave

If you could make htat change

That's not intuitive - I can see using a stronger pull-up (lower resistance value) but not the other way around.I did change out my PU resistor from 4.7K to 10K to see if that would help and interesting in that it was running for a long time without a failure.

That's not intuitive - I can see using a stronger pull-up (lower resistance value) but not the other way around.

Ill keep it running and report back

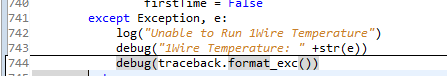

you need to remove the trace_back.print_tb line. you removed the definition for exc_tracebackPerhaps I didnt update the code properlywith that second error message.

did you make sure the config.py has debug enabled?d23029 today but I don’t get any further detail in /var/log/rpints.log.

did you make sure the config.py has debug enabled?

config['flowmon.debug' ] = True

Or change the debug lines (748-749) to log in FlowMonitor.py?

restart just the flomonitor service to load new codeDo I need to completely restart the pi machine or just restart the flow monitor to loan the new code?