The concept is very simple. It is my method of chilling 20 gallon brews.

The practical application is daunting, and while I love what it is I have achieved, I am not sure if it was the best approach.

My initial write up on this can be found here.

The Grossy Wort-Chiller/Fermentation Chamber 3000.

https://www.homebrewtalk.com/showthread.php?t=476429&page=3

I had to take a break from the project, but have made a lot of progress lately. And I will be posting that progress shortly.

Here is what you need to know.

This will of course depend on the size batches you do. (If under 15 gallons I would recommend not doing this and just get a freezer or refrigerator.)

OK here we go.

The bucket of water in your freezer is going to heat up, (the pump wont be why). You are transferring heat from the fermentor to your bucket. Your freezer needs to respond. But it will do so very slowly. Chest freezers are made for long and slow chilling (crazy energy efficient), an upright freezer would respond faster.

If your bucket is warming up faster than the freezer can chill, the system will fail.

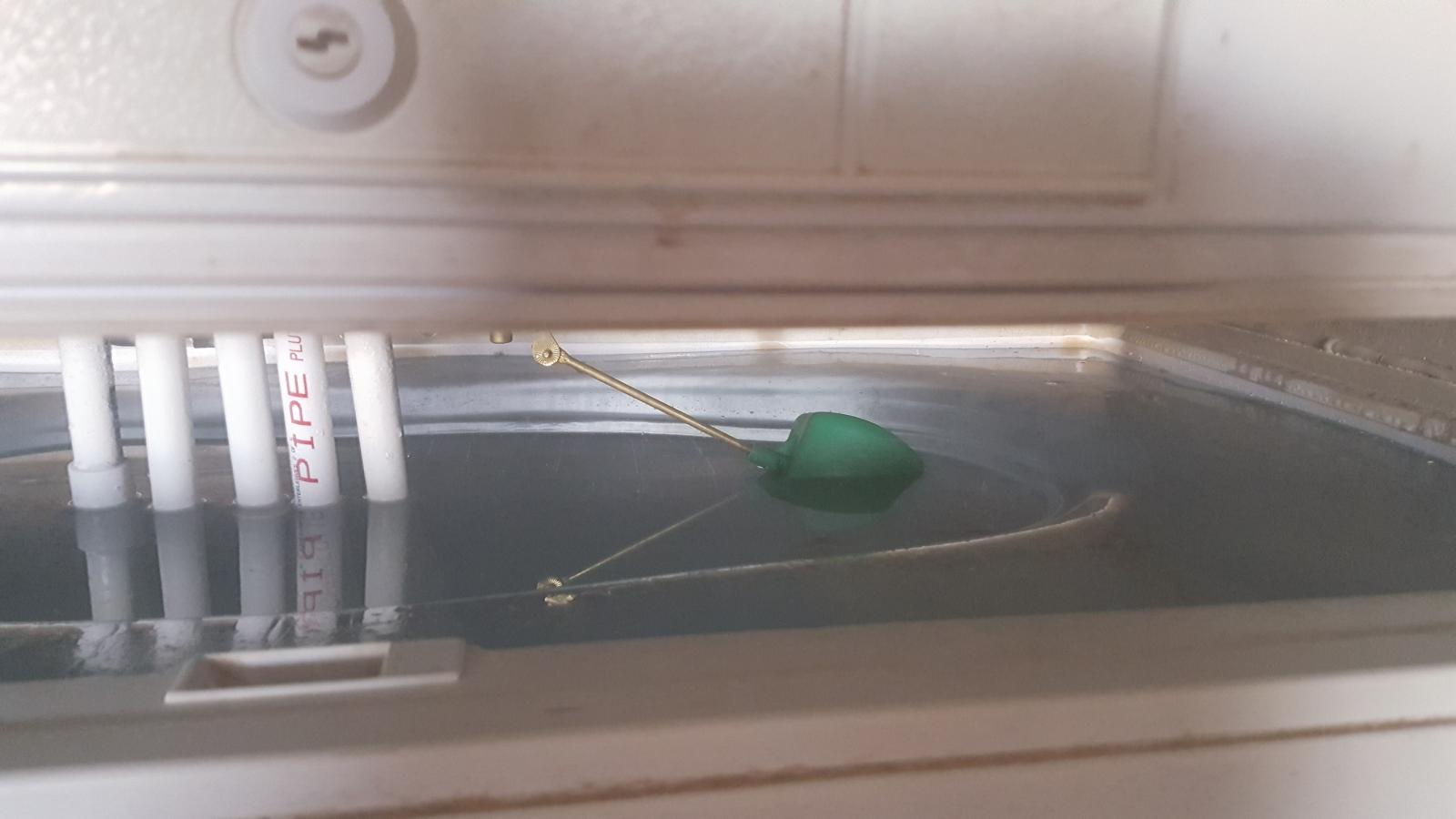

I use a 100 gallon chest freezer, and I freeze 20% of it to ice. Which forms an ice torus around the top of the chest freezer. The ice acts as a thermal mass that can absorb a lot of heat, and allows the chest freezer to respond. My system works perfectly.

I have reservations that a bucket in a freezer will have the thermal mass necessary to cope.

My first attempt at this failed, because I did not make ice. In the winter time my 100 gallons of 33 degree water warmed up to 46 degrees during fermentation. Which made chilling the wort down to 67 degrees very difficult. I knew it would never work in the summer.

You must place the pipes/tubing in the middle of the bucket, ice will form and freeze your pipes if they are near the sides.

The pipes/tubing must have a very short travel out of the freezer, or they will freeze.

Ice is your friend and your enemy, it is a balancing act.

I am fermenting 20 gallons of IPA as of this write up.

The last picture shows the temperature inside the fermentation chamber (to the left), the temperature inside the fermentor (right).

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)