The Pol

Well-Known Member

- Joined

- Feb 12, 2007

- Messages

- 11,390

- Reaction score

- 120

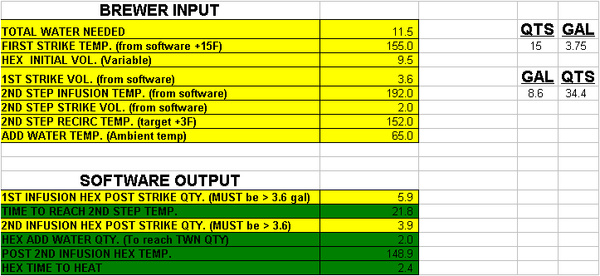

Sure, I have emailed these spreadsheets to all of those who are building the system too, they are needed and make brew day mindless.

Total water needed: This comes from Promash, this is the total water needed to reach my target pre-boil/post boil volume. I have to buy water to brew, so this is handy.

First Strike Temp: This is the strike temp calculated by Promash for the protien rest. I add 15F to preheat my MLT.

HEX Initial Volume: This is the initial volume of water heated in the HLT.

1st Strike Volume: This comes from Promash, this is the protien rest infusion.

2nd Step Infusion Temp: This comes from Promash, this is the infusion temp to reach my desired sacc. temp.

2nd Step Volume: This comes from Promash, it is the qty. at the afore mentiotned temp, to reach sacc. rest.

2nd Step Recirc. Temp.: This is the HLT temperature for the sacc. rest recirculation. My differential in my system is 3F.

ADD Water temp: This is the temp of the water that is added to the HLT AFTER the step infusion to bring the mash to sacc. rest temp. This cools the HLT to the recirc. temp. This water is also NEEDED to reach the needed water for sparge.

It calculates the following:

1st Infusion HEX Post Strike Qty.: This is what is left in the HLT AFTER the inistial strike infusion, to verify the element stays wet.

Time to Reach Second Step TEmp: This is the calculated time to reach my sacc. infusion temp in the HLT.

2nd Infusion HEX Post Strike Qty: This is the HLT qty. after the SECOND infusion, the infusion to reach sacc. rest. This verifies the element is still wet.

HEX Add Water Qty: This is the water needed to add to the HLT AFTER the sacc. rest infusion to reach the TOTAL WATER NEEDED qty from Promash. This water also cools the HLT to sacc. recirc. temp.

Post Second Infusion HEX Temp: This is the temp of the HLT AFTER the afore mentioned cool water infusion to the HLT

HEX Time To Heat: This is the time that it will take the HLT to reach the desired sacc. recirc temp after the cool water infusion.

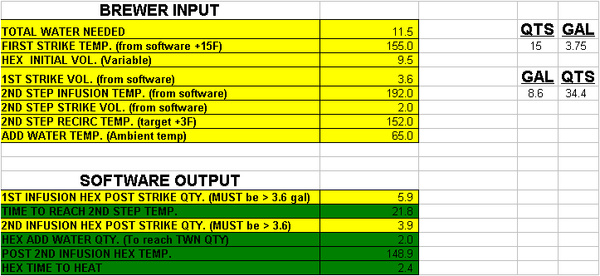

Total water needed: This comes from Promash, this is the total water needed to reach my target pre-boil/post boil volume. I have to buy water to brew, so this is handy.

First Strike Temp: This is the strike temp calculated by Promash for the protien rest. I add 15F to preheat my MLT.

HEX Initial Volume: This is the initial volume of water heated in the HLT.

1st Strike Volume: This comes from Promash, this is the protien rest infusion.

2nd Step Infusion Temp: This comes from Promash, this is the infusion temp to reach my desired sacc. temp.

2nd Step Volume: This comes from Promash, it is the qty. at the afore mentiotned temp, to reach sacc. rest.

2nd Step Recirc. Temp.: This is the HLT temperature for the sacc. rest recirculation. My differential in my system is 3F.

ADD Water temp: This is the temp of the water that is added to the HLT AFTER the step infusion to bring the mash to sacc. rest temp. This cools the HLT to the recirc. temp. This water is also NEEDED to reach the needed water for sparge.

It calculates the following:

1st Infusion HEX Post Strike Qty.: This is what is left in the HLT AFTER the inistial strike infusion, to verify the element stays wet.

Time to Reach Second Step TEmp: This is the calculated time to reach my sacc. infusion temp in the HLT.

2nd Infusion HEX Post Strike Qty: This is the HLT qty. after the SECOND infusion, the infusion to reach sacc. rest. This verifies the element is still wet.

HEX Add Water Qty: This is the water needed to add to the HLT AFTER the sacc. rest infusion to reach the TOTAL WATER NEEDED qty from Promash. This water also cools the HLT to sacc. recirc. temp.

Post Second Infusion HEX Temp: This is the temp of the HLT AFTER the afore mentioned cool water infusion to the HLT

HEX Time To Heat: This is the time that it will take the HLT to reach the desired sacc. recirc temp after the cool water infusion.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)