Great build, I'm convinced this is the way for me to go now! I have limited space in my garage and I like the narrow footprint over the chest freezer

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Upright Keezer, 8 taps, 11 kegs

- Thread starter JonW

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

SavoryChef

Well-Known Member

I just received all my taps and shanks for this build. I can't wait

m3n00b

Well-Known Member

Curious what line lengths you used on the liquid side.

SavoryChef

Well-Known Member

10 feet minimum

Curious what line lengths you used on the liquid side.

8 feet.

JonW, you've inspired me as well as others!!! Thanks! Not trying to copy you, but I have a 20 cu.ft frigiidaire. I got it home,cleaned it, took shelves out, it looks almost new, hardly used! I think it's a 07 or 08 model. It doesn't have a handle on front, it has a small grip handle on edge of door, other than that the interior looks identical to yours! Looking at yours you have plenty of room for stacking kegs! I measured mine from top to bottom it's only 57 1/4".my kegs are used ball lock, 25" tall. Not leaving me much room! What's your thoughts on this? Thanks!!

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$27.29 ($13.64 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$39.22 ($39.22 / Count)

Brewer's Best Home Brew Beer Ingredient Kit - 5 Gallon (Mexican Cerveza)

Amazon.com

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid MFL)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

slarkin712

Well-Known Member

I built a setup nearly identical to this. I just went and measured the interior height of my freezer and it was 57 1/4" (Mine is a frigidaire as well). I easily fit two levels of ball lock kegs. The top shelf is 29" above the floor (I had to build a shelf from 2x2 and 2x4 as the stock shelf location was not well placed). I can put sanke kegs on the bottom, although it is a tight squeeze height-wise. If I could do it again I would make the top shelf 1" higher so I could more easily get sanke kegs on the bottom. Hope that helps.

8 feet.

With flow control faucets I am getting away with only 6ft lines going to each tap and thats is even using Accuflex bev seal line.

You'll be fine with that. Just get your shelf positioned at the mid point so you end up with an equal amount of head space above each level of kegs. I used the wire shelf (with supports) to minimize the amount of shelf space lost. Additionally, I was able to mount the CO2 valves in the 2x2 recess of the shelf.I measured mine from top to bottom it's only 57 1/4".my kegs are used ball lock, 25" tall. Not leaving me much room! What's your thoughts on this? Thanks!!

I should be pretty easy to shim up the legs another inch.If I could do it again I would make the top shelf 1" higher so I could more easily get sanke kegs on the bottom. Hope that helps.

I found that 8' gave me good room for the door to open and gave me plenty of slack for attaching and moving kegs on the shelves. I could have gone shorter, but the extra distance just helped all around.With flow control faucets I am getting away with only 6ft lines going to each tap and thats is even using Accuflex bev seal line.

Thanks to everyone for your help! It's pretty much done, except for filling it up with beer!!! I'm only doing 6 for now and keep my co2 in fridge! Thanks!!!

Looks great! Get 'er filled!

Nwalesmith

Well-Known Member

benco said:Thanks to everyone for your help! It's pretty much done, except for filling it up with beer!!! I'm only doing 6 for now and keep my co2 in fridge! Thanks!!!

Where did you get your hardware? How long are your shakes? Can u share the measurements on the stand?

Looks awesome!

Where did you get your hardware? How long are your shakes? Can u share the measurements on the stand?

Looks awesome!

I know you were quoting benco, but since this is my build thread and mine is setup the same, I'll give you my dimensions.

The shelf is 17" deep x 27" wide x 29.5 high. My shanks are 3.5" w/ 90 degree tail pieces. Most likely any 3" to 4" shank will work.

Nwalesmith

Well-Known Member

Thanks!

rhe perlicks are birdman brewing!benco said:I got my perlicks. 525 ss 4 inch shank and tail piece combo set for 56.99 each, a good price. I think they had them for 54.99 Black Friday deal. I got all other misc. parts at keg connection.

the perlicks are birdman breiwing.benco said:I got my perlicks. 525 ss 4 inch shank and tail piece combo set for 56.99 each, a good price. I think they had them for 54.99 Black Friday deal. I got all other misc. parts at keg connection.

I needed extra tap space over Thanksgiving so I converted my upright freezer that I've been using for fermentation, into a dual purpose fermenter/keezer using John W.'s excellent inspiration. I needed at least four more taps for beer, so that's what I added. I also added a wine tap, and spaced them all so that I'd have room to expand. I painted the freezer black to help dress it up a little. I used perlick 525SS faucets along with a the stainless rotary valve tap for the wine (I got this from Micromatic). The wine sits outside the freezer in a 2.5 gallon keg, and the line is fed through the freezer to the tap. I used 3 1/8" ss shanks with 90 degree tailpieces like John did. I used some branding on demand (BOD) handles (also from Micromatic) so that I could label the beer. This was a great project that only took a couple of weeks from decision point through ordering and building to being able to serve out of it. It's great to see people's faces when they come into my basement and see 8 beers and a wine on tap!

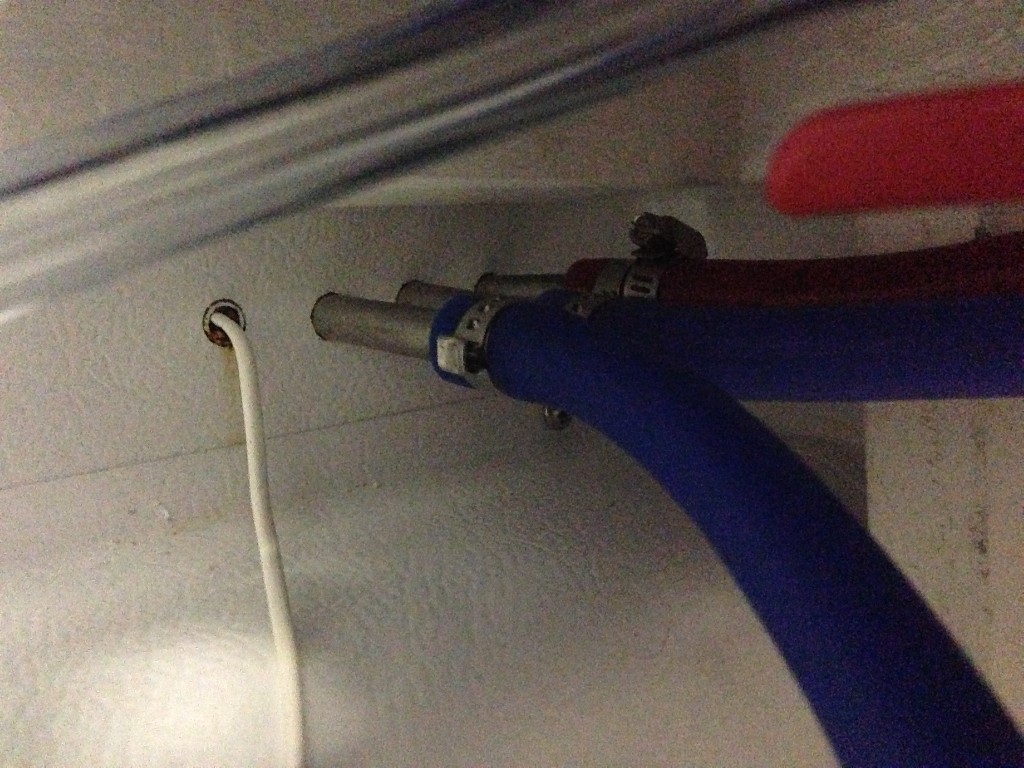

I drilled 4 holes through the back wall. One hole is for my temp probe and the other 3 are for gas lines. I used 3/8" SS tubing bent in a 90 degree radius to poke through the back wall. I then crimp on the 5/16" gas lines to the SS tubing on both the inside and outside. This makes it clean on the inside and also gives the bend on the outside to minimize the space behind the keezer so you can push it all the way against the wall.

JonW

just ordered everything to build one of these as well - how did you determine where it was safe to drill the holes in the back wall? Does this freezer have cooling lines in the sides?

JonW

just ordered everything to build one of these as well - how did you determine where it was safe to drill the holes in the back wall? Does this freezer have cooling lines in the sides?

The side have coils - which is why they'll heat up a bunch while the freezer is cooling.

For the back, almost the whole back panel is an air channel. You'll see on yours that the air is pulled in from the bottom and is pushed out the top. As long as you're not drilling in the lower hump area where the chiller coils are, you're safe. Take a look at my pic and drill in the same general area right above the hump. You can remove the hump cover to see where the components are inside if that helps you.

Thanks for the additional info. I'll be sure to post some pics next month when it's done!

JonW

just ordered everything to build one of these as well - how did you determine where it was safe to drill the holes in the back wall? Does this freezer have cooling lines in the sides?

I drilled through the floor of the freezer for my build. I unscrewed the back protective cover over the coils, and found a spot to drill through. Then I routed my lines up through a slot in the cover.

coming up through the floor is another good idea - thanks

I went with the Johnson digital controller and having some trouble. I've been keeping it around 34, in my garage. I have 2 beers on tap, the two kegs are on the upper shelf. My beer line is freezing up! Twice already. It's 3/16 bev line about 8 ft. Am I keeping it to cold or something else going on, any ideas? Thanks!

m3n00b

Well-Known Member

I went with the Johnson digital controller and having some trouble. I've been keeping it around 34, in my garage. I have 2 beers on tap, the two kegs are on the upper shelf. My beer line is freezing up! Twice already. It's 3/16 bev line about 8 ft. Am I keeping it to cold or something else going on, any ideas? Thanks!

34 is too cold for most beer unless it's american adjunct(piss) lager. I keep mine at 40.

34 is too cold for most beer unless it's american adjunct(piss) lager. I keep mine at 40.

I keep mine at 34 also, but that is for 2 reasons. 1) It allows me to have really short lines of the accuflex bev seal lines (which has very little resistance due to the glass barrier) 2) allows me to lagger beers

Sure, I have to let most beers sit a minute or two before they are ready to drink. I can live with that.

slarkin712

Well-Known Member

I went with the Johnson digital controller and having some trouble. I've been keeping it around 34, in my garage. I have 2 beers on tap, the two kegs are on the upper shelf. My beer line is freezing up! Twice already. It's 3/16 bev line about 8 ft. Am I keeping it to cold or something else going on, any ideas? Thanks!

For my tastes 34F is a little cold, but you can definitely make that work. Are the beer lines sitting on the floor of the freezer or near the back? I've had this happen to me before. Try to move the extra slack in the lines as close to the door as possible, and keep them off the floor of the freezer. Also, there will be cold/warm spots in the freezer. Maybe consider adding a fan that runs all the time to help keep the temp even. Another good thing to do is set your temperature probe into something with some mass, so that it will read more closely to the keg beer temperature and not the air temperature. I put my probe in a used White Labs yeast vial filled with sand. I placed this on top of one of the kegs on the lower shelf near the back. This should also keep the fridge from cycling on and off frequently.

FredTheNuke

Well-Known Member

SWMBO is NOT happy with you folks now that I have read this thread and found the 20.5 cf Frigidaire on sale at Lowe's!

SavoryChef

Well-Known Member

Similar threads

- Replies

- 3

- Views

- 1K

Latest posts

-

Factors affecting Water Chemistry Calculations (Oh no, not again!)

- Latest: BrewnWKopperKat

-

-

-

-

-

-

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)