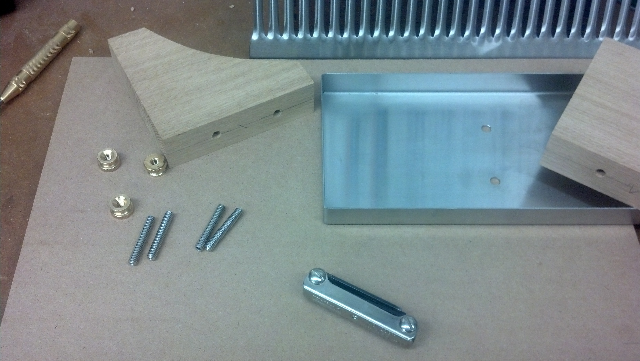

Has anyone thought about using Disconnects for their lines, so when not in use they can be removed? It would also make it easier to hook up their kegs outside, and than put them in? The come in valved and nonvalved, if you wish to prevent leaking.

I ran the numbers and I can outfit my 11 tap (beer lines are valved, gas is nonvalved) with everything it needs for $110...

http://www.usplastic.com/catalog/item.aspx?itemid=84241&catid=743

I noticed that some homebrew shops sell these for about $20/set, might as well cut out the middle man, they are around $7 a set from USPlastics...

I've been thinking about getting a few of these but for the purpose of removing my co2 tank easily for when I need to attach it to my jockey box.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)