Direct fire kettles. Maybe.

I was in the same boat as you using a 12 gallon igloo cooler. Slightly too big and required step mashing to maintain temps. I really disliked the plastic in my brewing process.

I seriously looked at the Anvil Foundry and chose to go with more durable/pro-grade equipment.

Anvil:

https://www.anvilbrewing.com/-p/anv-foundry-10.5.htm

Stout:

https://conical-fermenter.com/brewing-systems-by-the-gallon/

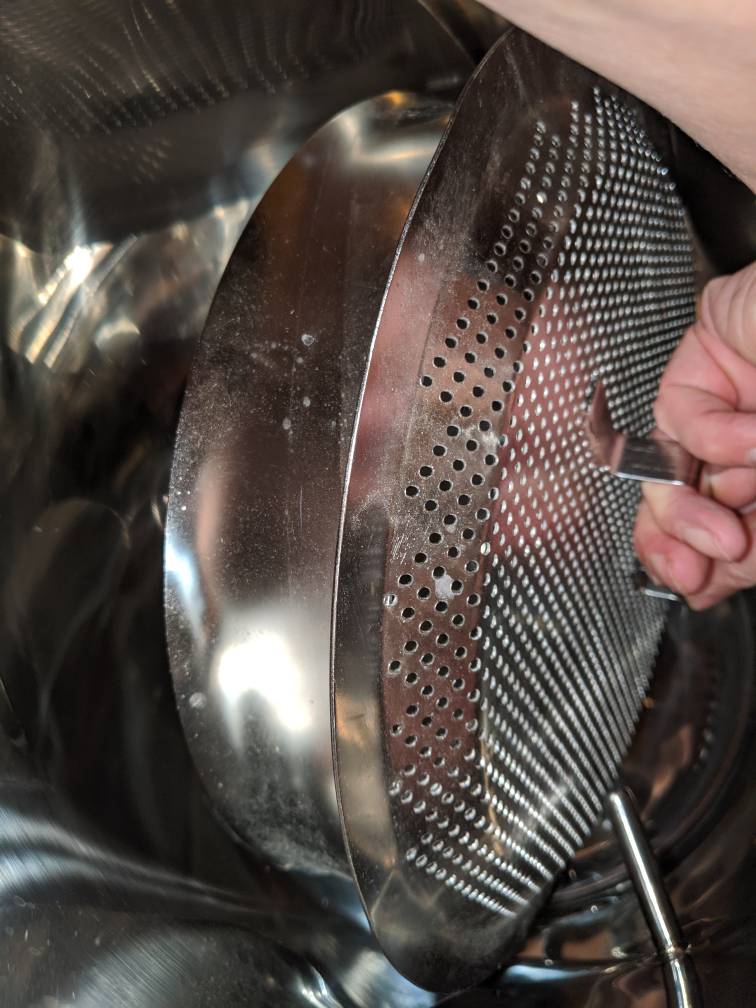

So, I just bought this. A Stout 9 gallon HLT and MLT. I typically do grain bills with 10lbs of grain. This is the ideal size if doing a no sparge.

View attachment 649506View attachment 649507View attachment 649508View attachment 649509View attachment 649510

First of all I want to thank you for the time you took to communicate. Your response is very thought provoking.

I do believe the time has come to move away from mashing in a cooler. A direct heat application sounds like the right approach. I am going to add some background. If anything this will allow me to order my thoughts and request advice as needed.

Vance Creek Brewery:

I discovered home brewing when I was 55 years old. This fact will become increasingly important as this thread develops. Few brewers stick to the hobby for the long term. I am to the point in my life where life changes need to be considered. If you continue following this convo you will find that thoughtful planning and design for the long term are part of the joy.

Starting out on the kitchen stove my first number of brews were extract kits.

Soon, five gallon all grain processes found their way into the brewery.

Within a year or so home brewing became my hobby.

Enjoying learning new processes I began developing a 10 gallon brewery.

At this stage I expanded my operations to include yeast harvesting, storage and building it up again. This meant I had to build DIY gear which I enjoyed making. Of course this stage meant controlled fermentation temps and converting refrigerators and building the controls. In other words I built and enhanced my brewery in planned specific stages.

I then decided to go to a 15 gallon dedicated brewery when I moved to the country in retirement. I had the space and time. I of course am now kegging, built my own kegerator etc.

Brewing all grain 10 gallon batches found me building my brew stand. A two burner propane system served me well. I eventually hooked the rig into my homes LP system. I was making the best beer I could as inexpensively as I could. Having two converted beer kegs I eventually sold them off and purchased large SS 25 to 35 gallon pots.

Build a stage...convert to higher level gear....planning....implementing......thinking ahead.

My 15 gallon build was a plastic fermenter. Like all of my builds the ideas and instructions came from Home Brew Talk.

After a couple of years I wanted to replace that fermenter with a SS conical. The one I choose was smaller at 14 gallons. At the time I did not want to give up that capacity. But, times change. As it turns out I have an opportunity to advance my brewery as it moves into a new stage of my life.

Do I convert to electric?

Do I downsize?

Must I consider a time when I may not have a dedicated brewing space?

The opportunity I have is to again review where I want to take this hobby and anticipate what it could look and feel like.

To be continued.....