I finally broke down and bought a SS conical fermenter, The BrewBuilt X3 Uni. I put a Blickman spunding valve on it to carb a lager but waited too long and it was not getting much more than a 1/2lb of pressure from slow fermentation at the end. So I decided to use CO2 to force carb. Checked all my TC fittings were tight as I could make them by hand and added gas, heading to 5 PSI. At right at 4-4.5 PSI the 8" lid blew off the tank, smashing the plastic QD's on the chill loop and luckily not hitting me. Scared the crap out of me! Then I got mad and felt stupid. Re-read the manual for the third time and they claim the tank can hold 15 PSI. That lids is around 50 square inches so 5 PSI puts 250lbs of force on that fitting, and 15 would be a whopping 750lbs of force. Question is can a triclamp fitting like the on my uni really withstand that type of pressure? I have been told forever to only hand tighten TC clamps but don't know if there is a design issue here or I am missing something important. Anyone else have a fermenter with a large lid held by TC clamps and if so have you successfully pressurized it without blowing fittings?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Unitank pressurization and TC Clamps question

- Thread starter stonebrewer

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

That’s obviously a Huge problem! Do you have any pictures or more information about the mode of failure? Was the triclamp still intact and in place after the lid blew off?

Usually when tightened appropriately the clamp fully captures the entire diameter of the lid so there is no way for a complete blow out unless the clamp hinge breaks.

Usually when tightened appropriately the clamp fully captures the entire diameter of the lid so there is no way for a complete blow out unless the clamp hinge breaks.

The TC must not have been aligned perfectly. I've had issues with them before. That would be my guess.

The clamp is the huge one, it ended up on the floor.

I checked at each of the gaps to be sure it was on correctly, but you may be right...gonna try to pressurize with just water once this batch is done and see if it repeats.The TC must not have been aligned perfectly. I've had issues with them before. That would be my guess.

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$172.35

2 Inch Tri Clamp Keg Manifold With Ball Lock Posts, Pressure Gauge, PRV (0-30 PSI) – Homebrew, Fermentation, Kegging System

wuhanshijiayangzhiyimaoyiyouxiangongsi

$33.95

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Bridgeview Beer and Wine Supply

$27.29 ($13.64 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$39.22 ($39.22 / Count)

Brewer's Best Home Brew Beer Ingredient Kit - 5 Gallon (Mexican Cerveza)

Amazon.com

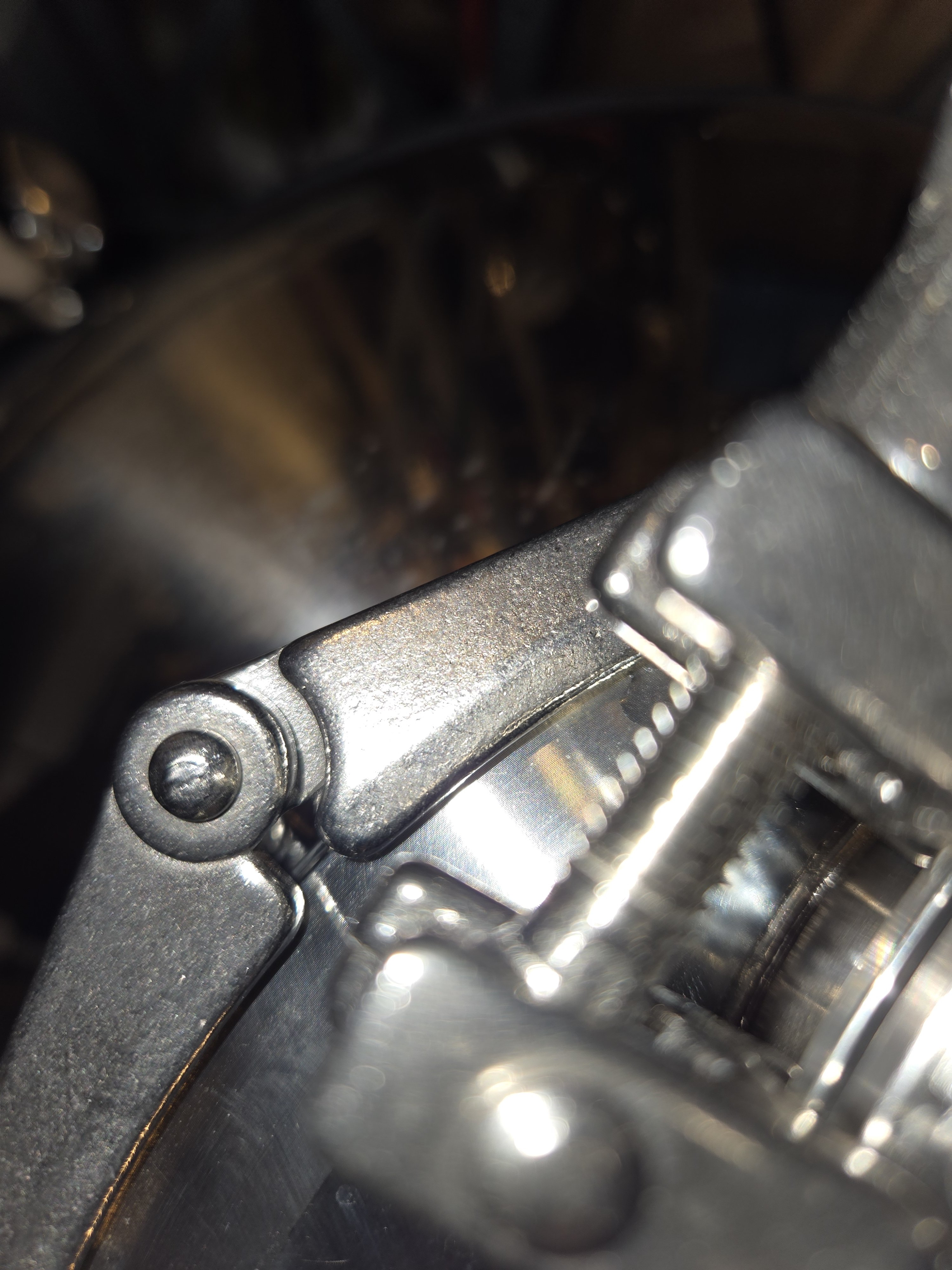

The clamp looks loose. The clamping surface is even with the flange of the lid. It should have the same overlap all the way around that lid. Larger lids need special attention to make sure the clamp is seated properly, even with that super nice clamp with 2 hinges. Really glad you weren’t hurt. Pressure kills. Just lookup split rims if you want to pucker.

From the user manual: "X3 Uni and Pressure Pack lid are rated at 15 psi"can a triclamp fitting like the on my uni really withstand that type of pressure?

The clamp looks loose. The clamping surface is even with the flange of the lid. It should have the same overlap all the way around that lid. Larger lids need special attention to make sure the clamp is seated properly, even with that super nice clamp with 2 hinges. Really glad you weren’t hurt. Pressure kills. Just lookup split rims if you want to pucker.

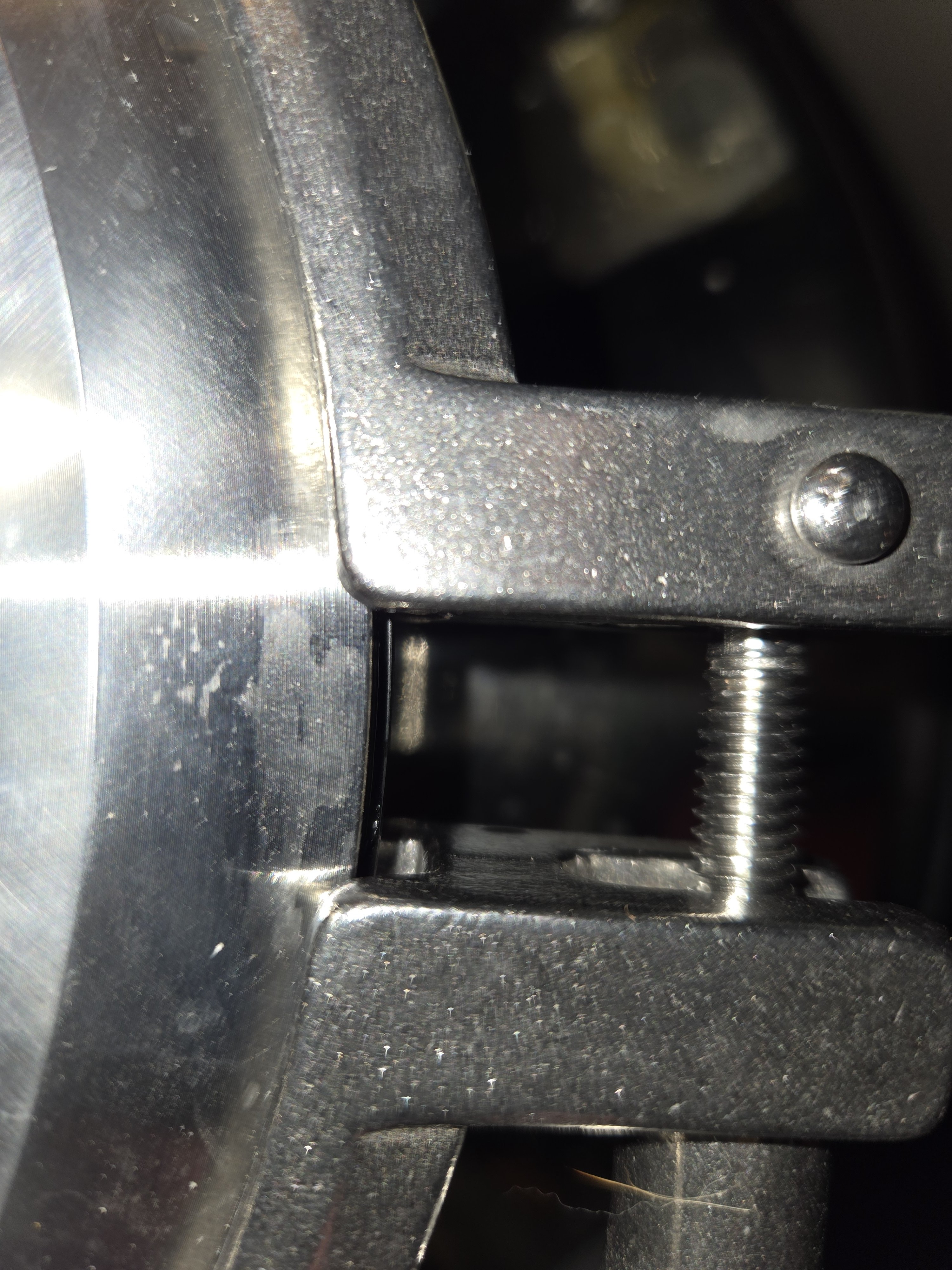

Three close up shots of the TC. I think it looks like it is not seated properly as well but it always looks just like this no matter how many times I put it on. Overlap appears to only be about 1/10 of an inch. This is the same for all the other smaller fittings as well...

Do the brewbuilt unitanks have the flanged gasket on the large port? That really helps to align it. Best of luck. Looks really slick. Would suck to not have confidence in it.View attachment 878249View attachment 878250View attachment 878251

Three close up shots of the TC. I think it looks like it is not seated properly as well but it always looks just like this no matter how many times I put it on. Overlap appears to only be about 1/10 of an inch. This is the same for all the other smaller fittings as well...

Yep, they are the EPDM ones from ForgeFit. Feels like it lines up perfectly. I check with a flashlight to make sure everything is in place. Hopefully my water test later will be a success. Otherwise I am going to be a pest to the vendor until they do something about it. So far its been over 24 hours and no replies, but it is the weekend so I will wait a bit before I end up calling them.Do the brewbuilt unitanks have the flanged gasket on the large port? That really helps to align it. Best of luck. Looks really slick. Would suck to not have confidence in it.

I'd try contacting Brewbuilt.

My impression is the don't cut corners on design, but maybe your lid isn't machined quite right or something.

My impression is the don't cut corners on design, but maybe your lid isn't machined quite right or something.

shoengine

Whale Noun Member

I have a fermentor with a 12in lid and the maker would not certify it to hold pressure with the triclamp only holding it (although with my lid at 15 PSI it has to hold 1695 lbs). The pressure rated clamp was bolted at each side, such as this one: https://www.gwkent.com/10in-hi-pressure-clamp.html

Since the documentation says it should hold the pressure it should do it with the supplied hardware. I did use my hinged clamp but chickened out around 5 PSI.

Since the documentation says it should hold the pressure it should do it with the supplied hardware. I did use my hinged clamp but chickened out around 5 PSI.

Apply a light coating of keg lube to all the surfaces inside the clamp and also where the wingnut spins/makes contact with the clamp fork.

You probably needed another 4-5 full turns of the wingnut to get it to properly engage the flanges. The lube as described above will get you more turns by hand pretty easily, but also don't be afraid to put pliers on the wing or a screw driver in the hole.

You probably needed another 4-5 full turns of the wingnut to get it to properly engage the flanges. The lube as described above will get you more turns by hand pretty easily, but also don't be afraid to put pliers on the wing or a screw driver in the hole.

Larger lids need special attention to make sure the clamp is seated properly

This wisdom may be completely correct and super valuable. fwiw, McMaster-Carr sells wing-nut tri-clamps of various sizes, claiming they handle much higher pressure. Their site says: "Wing nut—These clamps tighten by hand, no tools required." Apparently, this is not true of the BrewBuilt 8 in. clamp.You probably needed another 4-5 full turns of the wingnut to get it to properly engage the flanges.

The BrewBuilt instruction manual includes many warnings, leading with "Failure to follow warnings could result in serious injury or death." However, regarding attaching the 8 in. lid, all it says is:

"Place the large 8" TC gasket and Lid Cap into the open port on the dome. Fasten using the 3-piece 8" TC clamp, being careful on installation to

keep parts aligned until tightened down to help ensure a complete seal."

Given the danger, BrewBuilt ought to provide more detailed instructions if, as indicated, one must take special actions (i.e., anything beyond hand tightening) to adequately tighten the big TC clamp.

DavidBD

Active Member

I believe they said to tighten the clamps by hand, but that seemed insufficient on the big 8" cover, perhaps because the gasket is new. I used a 1/2" diameter wooden dowel to tighten the 8" clamp just until it looked even all around. A quick spray of Star San solution helps when trying to seat the gasket, but keg lube sounds like a good idea, too.

By the way, I orient the 8" and 4" hatch covers so the beer out post is at the edge of the unit. That way, any drips from my NukaTap simply fall on the table instead of falling behind the neoprene jacket.

By the way, I orient the 8" and 4" hatch covers so the beer out post is at the edge of the unit. That way, any drips from my NukaTap simply fall on the table instead of falling behind the neoprene jacket.

bruce_the_loon

Well-Known Member

Stainless steel is notorious for being "sticky" and feeling tight when it actually isn't. From those pictures of the clamp, my feeling is that it isn't tight enough. The TC clamp works by pulling the slot onto the sloped faces of the cap and bulkhead fitting and slowly compressing the seal as it does. This requires more force on the clamp than would be apparent by a "tighten by hand" instruction.

With "sticky" threads, it may feel tight, but it isn't actually. Also when I tighten mine by hand, I still use a lot of force to turn the wing nut tighter. Just spinning it in until it stops turning is not enough. Don't fear the force.

With "sticky" threads, it may feel tight, but it isn't actually. Also when I tighten mine by hand, I still use a lot of force to turn the wing nut tighter. Just spinning it in until it stops turning is not enough. Don't fear the force.

I've got a couple of X3 and haven't had any issues - but I do tighten the 8" about an additional full turn beyond hand tight. Also worth just looking at the gasket being squeezed in the gap. I build up the X3 during mash and then do a pressure test and leave it pressurized during the rest of the brew day just to make sure it's holding.

Brewbuilt have publically stated that the X3 is fine at 30psi and that the 15psi rating just reflects the limit of the PRV it ships with. In addition, an 8" tri-clamp fitting is generally rated to 100psi so there's nothing inherently wrong with the design choice.

Brewbuilt have publically stated that the X3 is fine at 30psi and that the 15psi rating just reflects the limit of the PRV it ships with. In addition, an 8" tri-clamp fitting is generally rated to 100psi so there's nothing inherently wrong with the design choice.

I'd be interested to know if there's a torque spec on the screw. I've never loved "hand tight" as a value. My brother's "hand tight" is probably 50% higher than mine, and mine is probably 200% higher than my mother's.

bruce_the_loon

Well-Known Member

I think the important spec is the compression of the seal between the two faces, which depends on both the nature of the seal (EPDM, silicone, teflon) and how well the channel on the clamp slides over the chamfered edges of the faces. Which depends in turn on the precision and smoothness of the machining of all the parts.I'd be interested to know if there's a torque spec on the screw. I've never loved "hand tight" as a value. My brother's "hand tight" is probably 50% higher than mine, and mine is probably 200% higher than my mother's.

I've got two identical clamps visually, but because of some slight roughness or sharpness in the machining of the wingnut thread, one needs a lot more torque on the wingnut to gain the same compression on the seal. Hand tight is an inaccurate way to describe what needs to be done with stainless steel TC fittings.

Given that torque measurement wouldn't accurately assure a TC fitting's safety in a potentially dangerous situation, we seem to be left with lubricating and then tightening the heck out of it. And then doing a pressure test without being in harm's way.

I used to think Spike's fermenter band clamp was hinky compared to TC. Not any more.

I used to think Spike's fermenter band clamp was hinky compared to TC. Not any more.

I think the risk is perhaps being over amplified here as tri-clamps this size and much larger are used in commercial and industrial settings everyday at much higher pressures. Just practice a bit of common sense and do a quick visual check of your work as you go and you're not going to have any leaks. Can't even fathom preferring a band clamp.

bruce_the_loon

Well-Known Member

All my tri-clamps are two part with the wingnut opposite the single hinge. I see the 8" one is a three part with two hinges. I wonder if that has a contributing factor to the releasing of the lid, making it more difficult to get an even alignment across the whole lid and leading to what feels like a properly tightened clamp that is not gripping evenly.

A question to OP, when the main lid is seated on the dome ring with the seal in place, are the edges of the lid, ring and seal flush with each other, forming a single vertical surface? If the lid is a slightly different diameter to the ring, it might not clamp properly.

Properly secured tri-clamps are way, way better than a band clamp, it's just that getting the alignment correct is important and if you are trying to align all the parts against gravity, it can be tricky when you are new to them.

My method is to do a loose fit first to get the clamp in place around the two faces so that it doesn't fall apart, then jiggle it to make sure both faces and the seal are fully aligned. A proper seal alignment should have both edges and the seal flush with each other with nothing sticking out and the seal seated in the grooves. Then tighten the clamp to the point where your fingers are being squeezed white and leaving a dent in the skin.

A question to OP, when the main lid is seated on the dome ring with the seal in place, are the edges of the lid, ring and seal flush with each other, forming a single vertical surface? If the lid is a slightly different diameter to the ring, it might not clamp properly.

Properly secured tri-clamps are way, way better than a band clamp, it's just that getting the alignment correct is important and if you are trying to align all the parts against gravity, it can be tricky when you are new to them.

My method is to do a loose fit first to get the clamp in place around the two faces so that it doesn't fall apart, then jiggle it to make sure both faces and the seal are fully aligned. A proper seal alignment should have both edges and the seal flush with each other with nothing sticking out and the seal seated in the grooves. Then tighten the clamp to the point where your fingers are being squeezed white and leaving a dent in the skin.

If a torque cannot be specified, there's no way to know it's tight enough. I'm sure there's a value in a manual somewhere.

edit: e.g. here's a table with wet and dry max torques https://www.aseptconn.ch/resources/Tri-clamp-torque-guide.pdf

edit: e.g. here's a table with wet and dry max torques https://www.aseptconn.ch/resources/Tri-clamp-torque-guide.pdf

bruce_the_loon

Well-Known Member

Looking at those torque ratings is interesting, is a human hand capable of reaching 54 lbf.in recommended for the 8" on the wingnut without a tool? I've got a torque screwdriver for electrical terminals that's rated to 45lbf.in and that's tough enough with a decently sized grip. So again, is the hand-tight recommendation fine for the 1.5" tri-clamps, but unsuitable for the 8" one? It would be interesting to get a load cell between two blanks and see what can be achieved.If a torque cannot be specified, there's no way to know it's tight enough. I'm sure there's a value in a manual somewhere.

edit: e.g. here's a table with wet and dry max torques https://www.aseptconn.ch/resources/Tri-clamp-torque-guide.pdf

Also, are all the clamps in home brew retail supply chains as precisely engineered as they should be compared to the Aseptconn ones. As I mentioned, I've got two clamps that look identical, but one galls more than the other.

I would think given the variation in how much different materials can bind and variation in the thickness and materials of the gaskets, that if there were a specification for securing a TC it wouldn’t be a torque value but maybe a clamp to lid overlap value. Like tighten until the clamp overlaps the edge of the fitting (lid) by 1/4 inch or something like that. The torque required to tighten a soft silicone gasket couldn’t be the same as the torque required to secure a ridged PTFE gasket right?

If you really zoom in on OP’s pictures you can see that the clamp only has a tiny bit of overlap past the edge of the lid. Maybe that’s the dimension to keep an eye on as we tighten the clamps.

If you really zoom in on OP’s pictures you can see that the clamp only has a tiny bit of overlap past the edge of the lid. Maybe that’s the dimension to keep an eye on as we tighten the clamps.

Last edited:

To be pragmatic about it, I think on the 5th usage of the unit, hand tight would have considerable more clamp overlap than the first tightening. If it were mine, I'd just crank the wingnut with a screwdriver in the hole and leave it like that for a day. The reason I recommend lubing the clamp is the same reason Spike and other makers of band clamp closures recommend tapping the band around the perimeter occasionally as you tighten. There is a lot of drag trying to get the clamp to slide into position when you're closing up at one point on the circle.

Worth watching this video and the subsequent ones about the unitank, I get the feeling it's tricky!!

- Joined

- Feb 16, 2012

- Messages

- 4,682

- Reaction score

- 7,138

- Location

- At home, in the brewery in Maryland.

I’m 75 years old, and my hand strength is nowhere near what it was 50 years ago.Looking at those torque ratings is interesting, is a human hand capable of reaching 54 lbf.in recommended for the 8" on the wingnut without a tool? I've got a torque screwdriver for electrical terminals that's rated to 45lbf.in and that's tough enough with a decently sized grip. So again, is the hand-tight recommendation fine for the 1.5" tri-clamps, but unsuitable for the 8" one? It would be interesting to get a load cell between two blanks and see what can be achieved.

Also, are all the clamps in home brew retail supply chains as precisely engineered as they should be compared to the Aseptconn ones. As I mentioned, I've got two clamps that look identical, but one galls more than the other.

However. My hand strength for grasping an 8” #2 Philips head screwdriver and inserting it into the eye-bolt hole of the clamp threaded clasp is sufficient leverage to ensure a proper seal.

My method: place the fitting onto the TC with a lightly lubed gasket (I prefer EPDM) and check for flush alignment of all the components. Then slightly rotate the fitting to ensure proper alignment. Then attach the clamp, rotate it over the ‘sandwiched’ pieces to ensure proper alignment of the clamp with the fittings. Hand tighten the bolt as far as you can using hand strength. Then insert the screwdriver shaft through the eye-bolt and use that leverage to torque down the clamp.

Never had a leak. Never had a blow-out.

Never say “never”. Lose any triclamp that has winged fittings on the bolt, and replace with eye-bolt fittings, but resist the urge to over-correct by over-torquing.

Last edited:

Worth watching this video and the subsequent ones about the unitank, I get the feeling it's tricky!!

If you're referring to him fighting with getting the gasket seated for the 8-inch TC port, yeah... it was a little tricky the first time. The gasket is folded during shipping and it didn't want to align to the port for me the first time.

However, if you dunk it in StarSan, it's nicely lubricated and it'll tend to slip right into the groove when the top goes on. The first time or two, I helped it by having one hand on the outside and one on the inside (through the 4-inch port) to guide it. After it had been in place for a while, it started to flatten out and I've had scarcely any trouble aligning it since.

I have about zero complaints with this unit. I'm very impressed with the build quality and the finish.

In light of stonebrewer's experience, I am going to be more careful with the 8-inch port. I know that I've had it over 5 PSI in the past, and I'm hoping that I didn't just get lucky. I've only ever tightened it to "hand tight" and not even excessively so, since I'd read that you don't want to over-tighten TC connections because you can damage the gaskets. Supposedly, tools shouldn't normally be used for tightening, although there may be exceptions for a clamp of this size.

Similar threads

- Replies

- 0

- Views

- 790

- Replies

- 4

- Views

- 1K

- Replies

- 105

- Views

- 6K

Latest posts

-

-

-

-

-

I just poured 42 bottles of HB Dunkelweizen down the drain

- Latest: IslandLizard

-

-

-