Wow, good to know, It doesnt seem like it could hold that much, but obviously it does... highest so far was 23 i think... and that seemed to be alot...

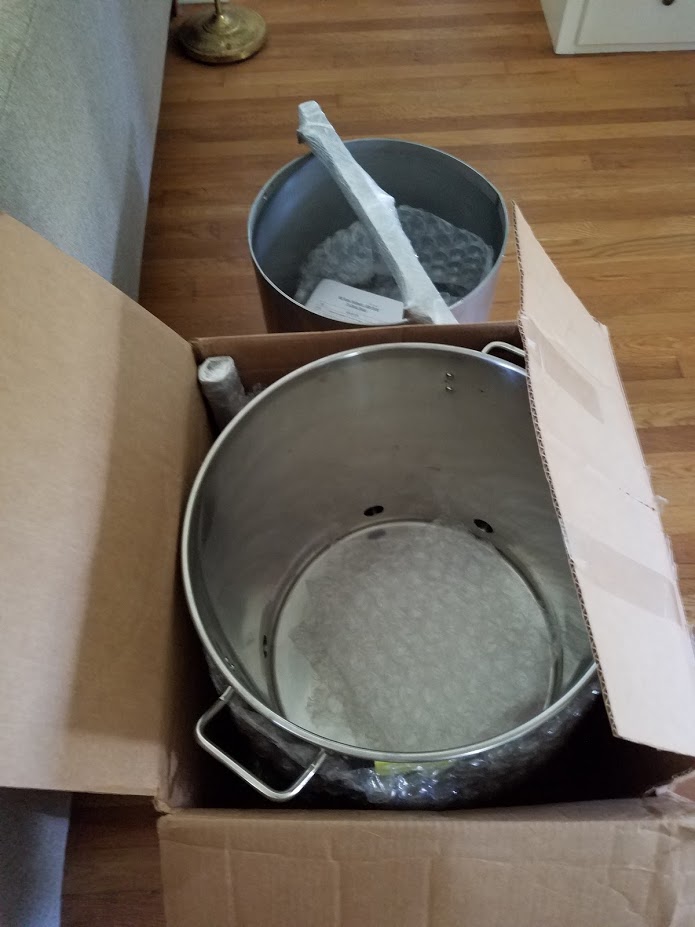

So my yellow rose came in with an OG of 1.07. That's a 11.5 gallon batch with 32lbs of grain. That about maxed out the kettle with 18 gallons of strike water View attachment 352979

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)

:rockin:

:rockin: