I am looking to improve the design and have some ideas. A glycol line chiller is out of the question.

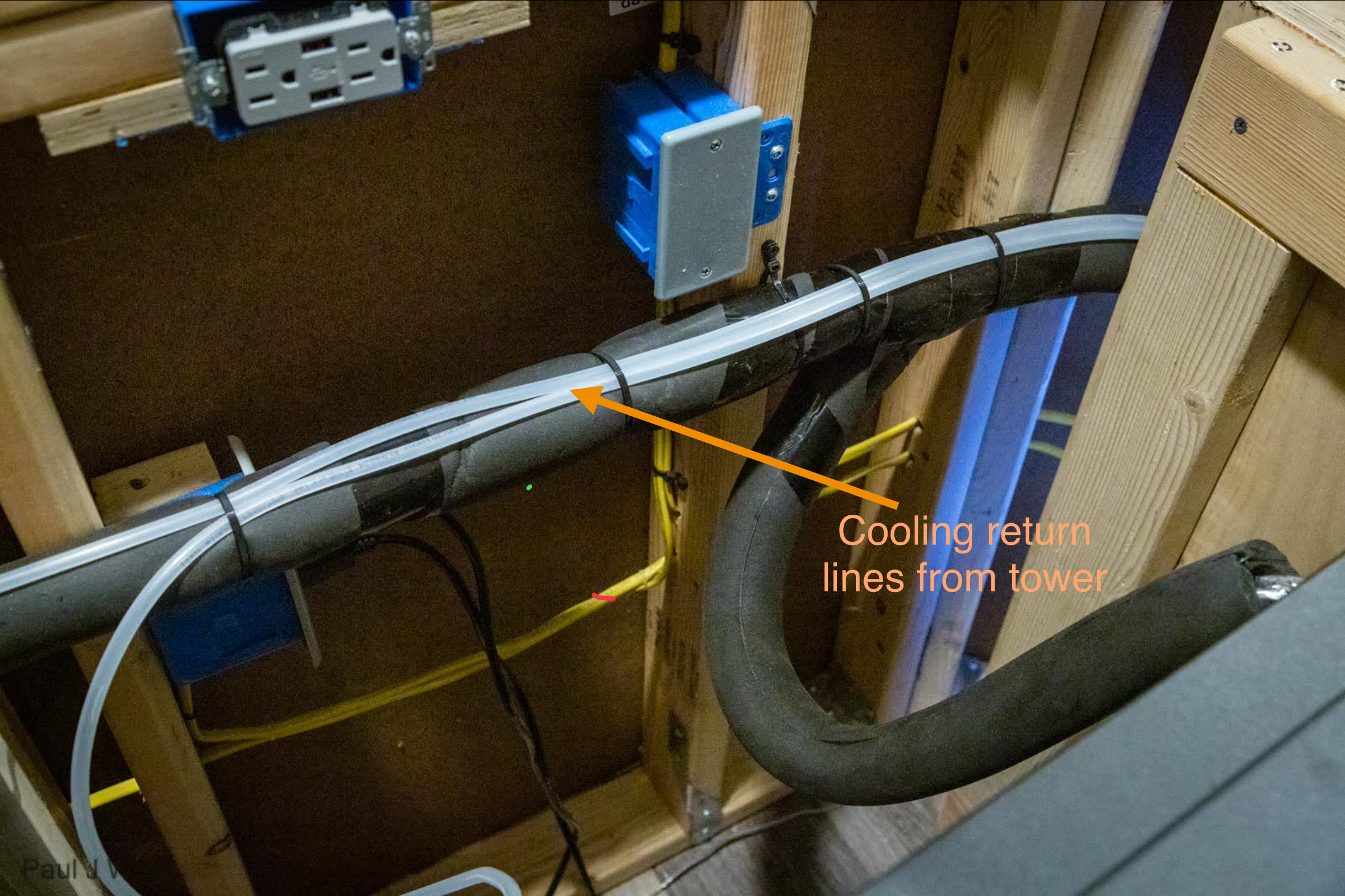

1) The water return line from the tower is not insulated and runs close to the back of the kegerators that get hot. I can easily insulate the return line which will keep the reservoir keg cooler.

2) I just ran a test with a similar submersible pump in a one gallon jug of water. The water started at room temp (72F) and over a couple of hours increased to 81F. I can replace the submersible pump with a regular pump exterior to the kegerator as the reservoir is obviously picking up heat from the pump.

3) I can add some 'water wetter' to the reservoir to increase the flow and more easily cool the product lines.

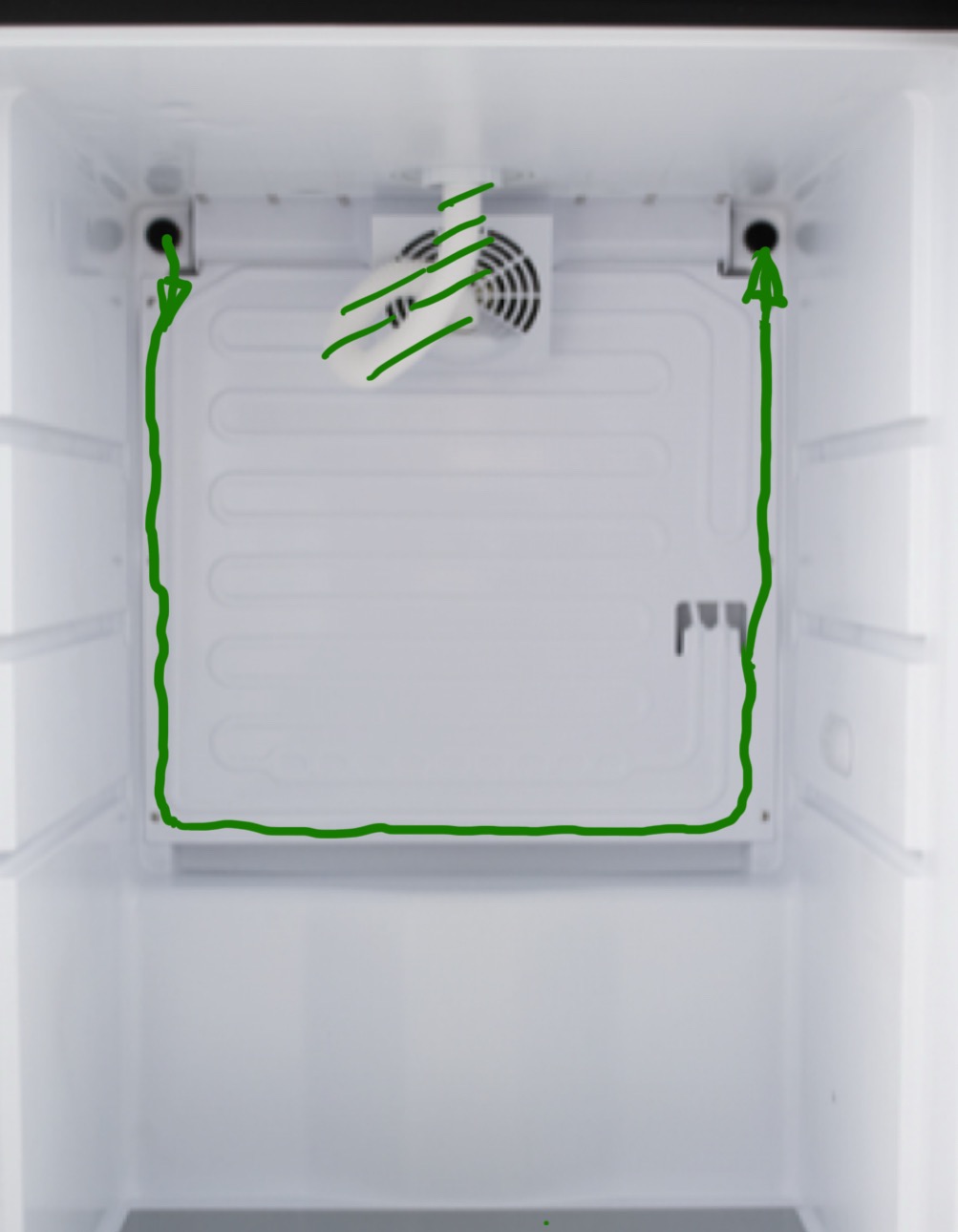

Any other ideas? The kegerators are under a 2" concrete bar top so cooling the tower using cold kegerator air is not an option.

Paul

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)