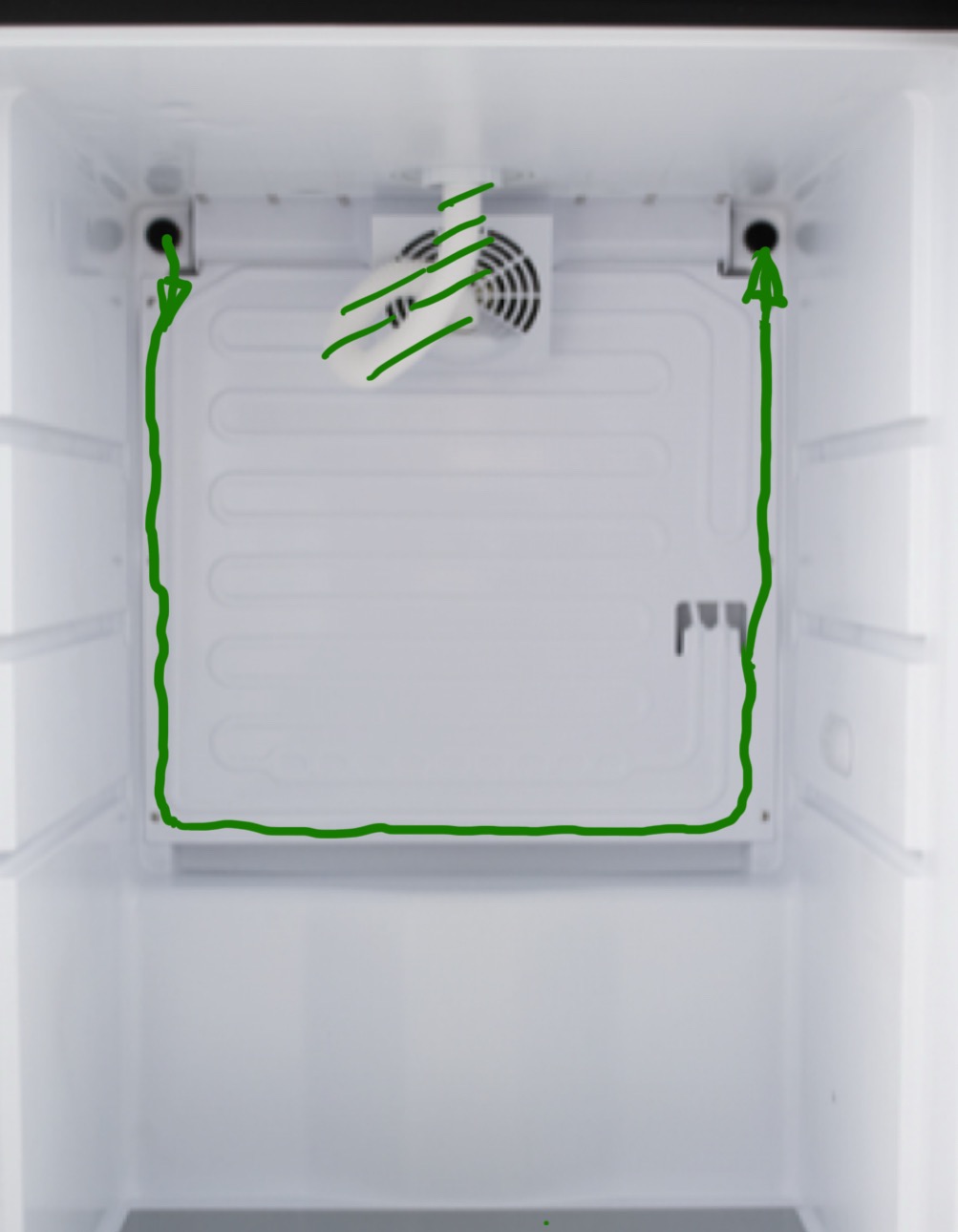

Before doing this, any ideas on how you could fasten the copper coil to the plate, to ensure there's close contact, without compromising the cooling system?

I am thinking that the input & output of the copper tube will be held by P-clips under the head of two of the screws that hold the Evap plate. If I straighten the malleable copper tube, it should be in contact with the plate or within a couple of mm. I could get some of that heat conducting foam tape that is used for 3D printer beds or under-floor heating. The Evap plate itself is not flat as it has passageways molded in it for the refrigerant. I could put a slight set on the tube so that when the screws are cinched down the tube is in contact with the plate.

I could drill through the Evap plate in between the pipes and hold the copper tube in place with zip-ties but that seems risky. I could also JB Weld the tube in place but that could get messy.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)