Jsslack

Well-Known Member

And 1 is on the left of both pictures - should it not go 1 - 2 - 3 on the front but 3 -2 - 1 on the back? as in the pale ale on tap 1 is flowing through hose 3?

Agreed

And 1 is on the left of both pictures - should it not go 1 - 2 - 3 on the front but 3 -2 - 1 on the back? as in the pale ale on tap 1 is flowing through hose 3?

Agreed

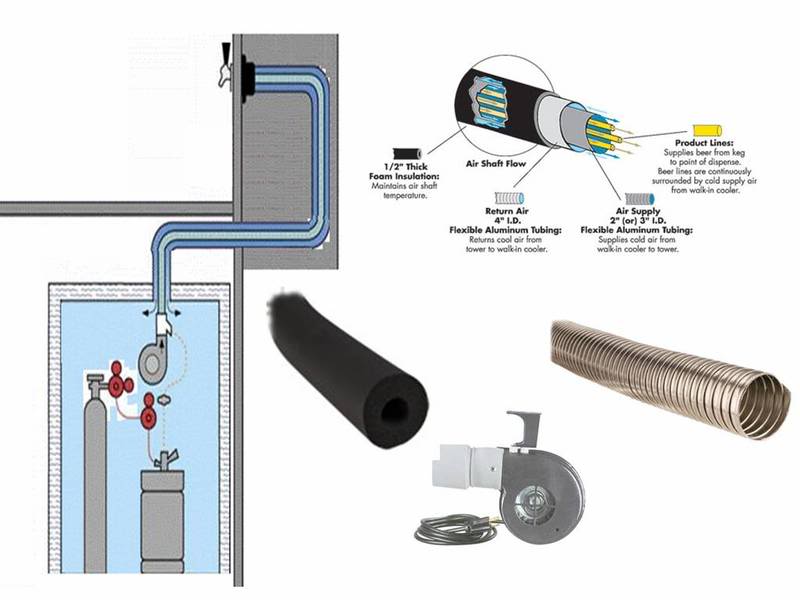

So, which way is the fan blowing on the non-beer-line PVC pipe? Is that supply air or return air? I would imagine it is supply air, but just curious.

Love your setup here and would like to incorporate this into the house I am in the process of buying. I had a couple questions for you.

- What type of latches did you use to secure the back of the box?

- Did you just silicone around the co2 hose that you ran through the side of the freezer?

- I'm far from an electrician, but how did you go about hooking up the computer fan?

Thanks for the help and great work

Thanks for the reply. Your "coffin box" is made out of plexi glass then? I guess I was assuming it was all wood lined with foam.

Sent from my iPhone using Home Brew

I copied your design of the box (airflow) as well as ran the piping higher to help distribute the cold airflow.

Works awesome! Thanks for the guidance!

Looks awesome!

I am in the process of a similar type of setup... What size collar / pvc did you go with? I'm debating between how large to get maximum air circulation.

Thanks!

Great build. Is there any way you can snap a pic of inside your keezer now that you are finished? I am looking at doing something essentially exactly the same. I am wondering where your fan is mounted on the inside of your keezer. I have a pretty good temp differential from the top and the bottom of my keezer as I haven't installed a fan yet (I don't have foaming issues so it hasn't been a priority). Unless I extend the 3" down into my keezer, I will be pulling pretty warm air into the box. Do you have a separate fan system inside your keezer or did you extend the 3" down into the keezer?

The warping problem you mentioned is great info for folks trying to do a similar build. Have there been any other things you have seen that have either been a problem or that you would improve? Any condensation problems anywhere? I did notice you installed some additional insulation inside the box compared to when you first built it. Was that to reduce the amount of airspace in the box? Thanks for the input.

Really nice setup.

I see four fans total, do you think that's overkill? I'm just wondering. I have one fan in my keezer, although it's a bit smaller than yours, I think it's plenty to move air.

I would add another fan if you think it's really doing something. Does it help with condensation? or is it just moving air?

I am not using that fridge as part of the setup anymore. I needed more taps. I was however using a few fans inside the keezer. I found that having them mounted to the collar with an alternating pattern of pushing and pulling air at a angled horizontal approach to work best. Make sure you use bearing fans and not bushing types for horizontal mounting, bushing fans wear out quickly when horizontal. You can use metal angle L brackets to mount the fans.

I did get a little condensation in the bottom of the keezer, but no more than most. To stop the pvc pipes from dripping I wrapped them in Hvac foil backed pipe wrap insulation. This really helped.

The extra insulation in the box was for the extra airspace, there was no need to have. The block in the middle was a piece of Styrofoam that I wrapped in foil tape. It helped reduce airspace and direct the incoming cold air right over the tap shanks.

I would recommend that anyone who builds this seals the area where the pipes go through the collar with silicone. I found a little mold on the wood when I pulled it apart.

See the pictures attached for info about the fans.

Hope this helps. Feel free to ask more questions.

Use 2 pipes, the airspace inside is cramped with the lines already, fitting the air hose inside would be a pita. Also getting good air flow through the small house in guessing is difficult without a higher power fan. Just my .02