Hi!

I'm brand new to this! You guys have the best hobby!

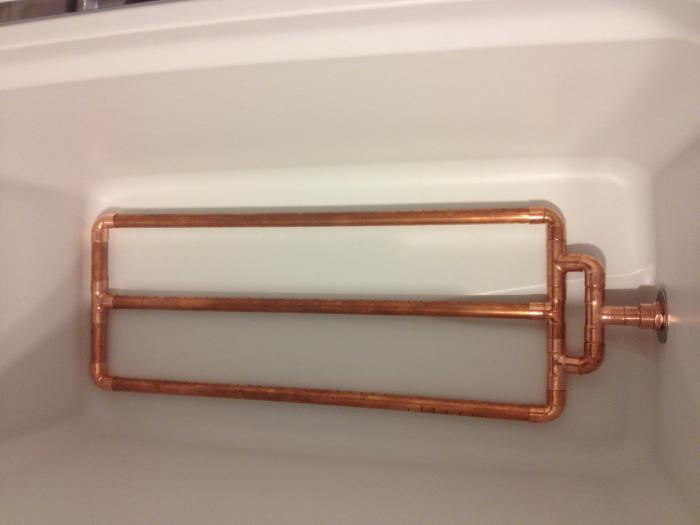

I'm designing my manifold for mash tun right now. I came across this design:

This would work for my cooler but I'm a little unsure about the arm that shoots out to the right? Can I get some veteran thoughts on this design? Also, would the slots only go on the longitudinal pipes?

This would work for my cooler but I'm a little unsure about the arm that shoots out to the right? Can I get some veteran thoughts on this design? Also, would the slots only go on the longitudinal pipes?

Thanks a lot for all your help.

I'm brand new to this! You guys have the best hobby!

I'm designing my manifold for mash tun right now. I came across this design:

Thanks a lot for all your help.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)